Track Drainage Solutions at the Pioneering Werrington Grade Separation Project

Case Study Details

Client

Morgan Sindall

Location

Peterborough, Cambridgeshire

Product

STAKKAbox™ ULTIMA & FLEXI-Pit™

Sector

Rail

Case Study

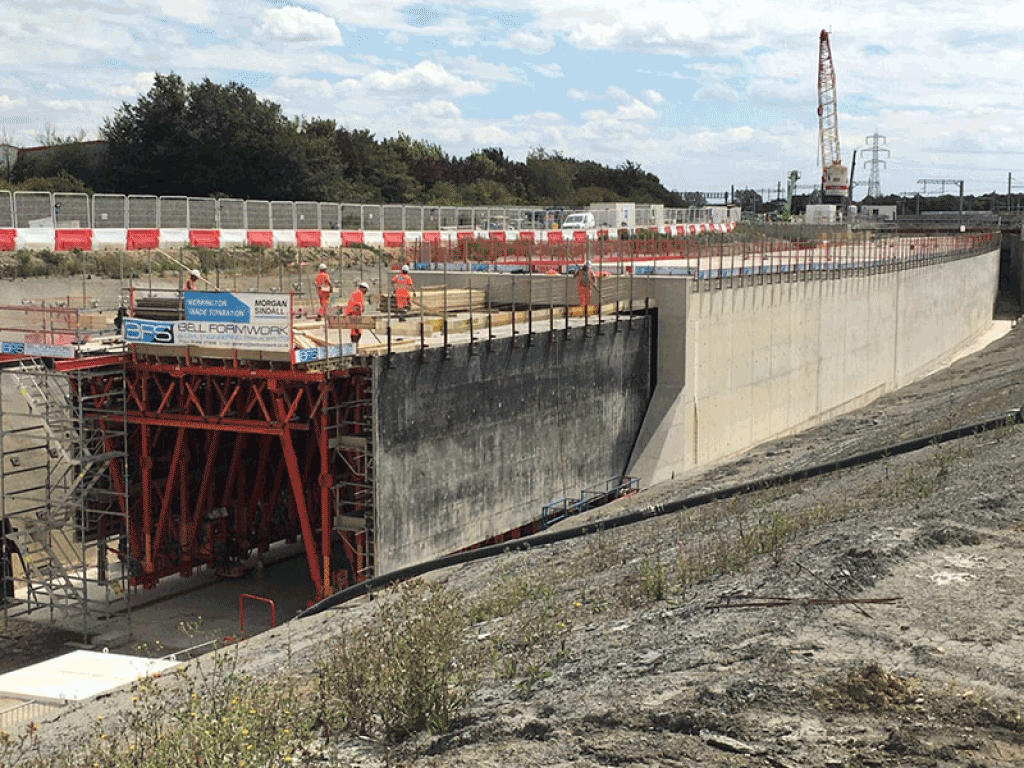

Working with Principle Contractor Morgan Sindall and Designers Mott Macdonald, Cubis’ were selected to support the trackside drainage system of the new dive under project on the East Coast Main Line (ECML).

The dive under was designed to increase capacity of passenger trains by creating an alternative route for the slow freight trains that historically have had to cross the busy main line at a flat crossing, causing passenger timetable constraints on the Great North Great Eastern (GNGE) and East Coast Main Line routes.

A new two track railway was designed to run underneath the East Coast Main Line, through the dive under, separating the freight trains from high speed passenger traffic

removing any stoppages for either services and increasing capacity for passenger trains in the future.

The dive under structure for the new track was the UK’s first “Curved “Box”, an industry-leading engineering technique that saw nine, interconnected sections pushed under the East Coast Main Line. The structure was 155m long, 9.5m wide and 5.1m high, with 1m thick walls, weighing over 11,000 tones.

With the site situated on a flood plain, drainage was a major concern. Cubis’ was approached early in the design stage by Mott Macdonald with a key focus on the range of drainage catchpit sizes available, to suit minimum internal dimensions required to satisfy Network Rail standards and to give the structural integrity required across the project with there being varying amounts of locations and applications that would require bespoke installations.

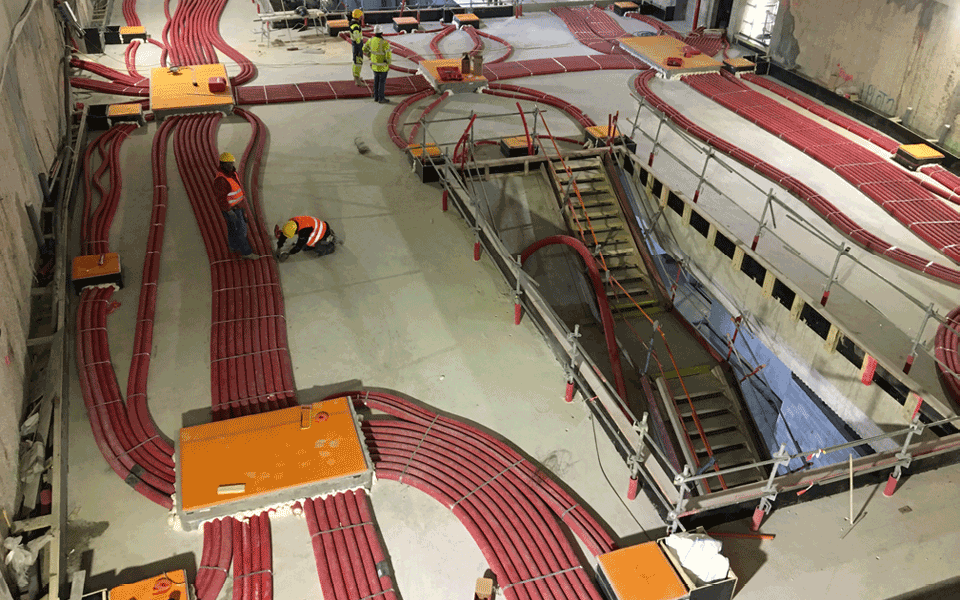

Cubis’ specification and technical teams worked closely with Morgan Sindall’s engineering team to provide a suite of detailed technical drawings to act as a library to choose from for the more standard chambers making the selection and ordering process much easier.

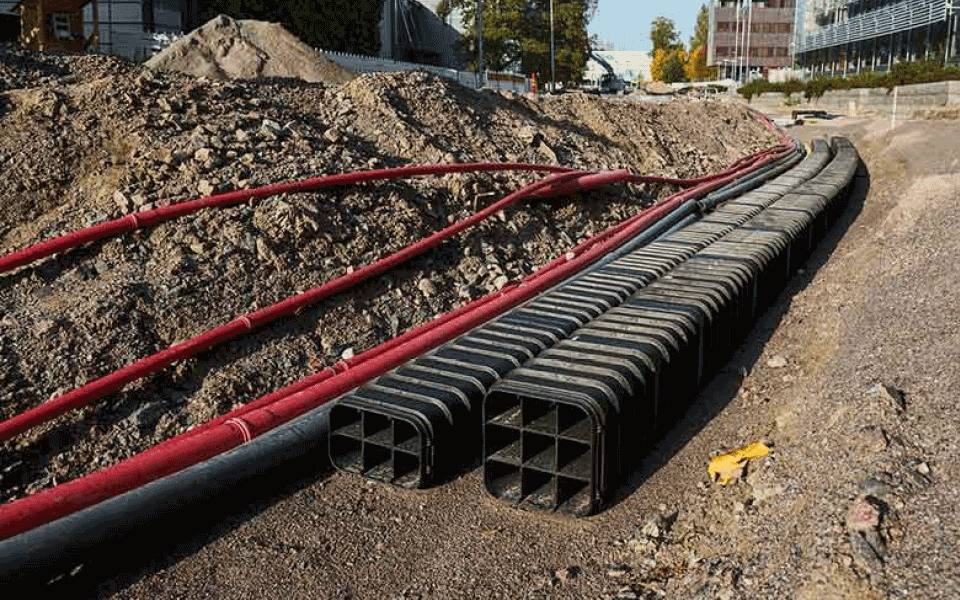

The Rail team at Cubis worked closely with Morgan Sindall throughout the project especially in regards to the more intricate design elements. Cubis’ FLEXI Pit drainage catchpit system was installed in a range of sizes from 1200 x 675mm to 1350 x 1350mm.

The lightweight modular and structural access chamber system allowed for a quick and easy installation with its unique sliding backfill barrier enabling easy adjustment to inlet and outlet pipe levels on-site. This provided time and cost savings for the contractor and the STAKKAbox™ chamber system removed any need for a concrete surround that would normally be required by other products.

Cubis’ Rail team supported Morgan Sindall throughout the design, specification, delivery and installation ensuring a carbon-friendly trackside drainage system was installed for the 1.2 billion East Coast upgrade.