Rail Communications and Signaling Upgrade (SEPTA)

Case Study Details

Client

SEPTA

Location

Pennsylvania, USA

Product

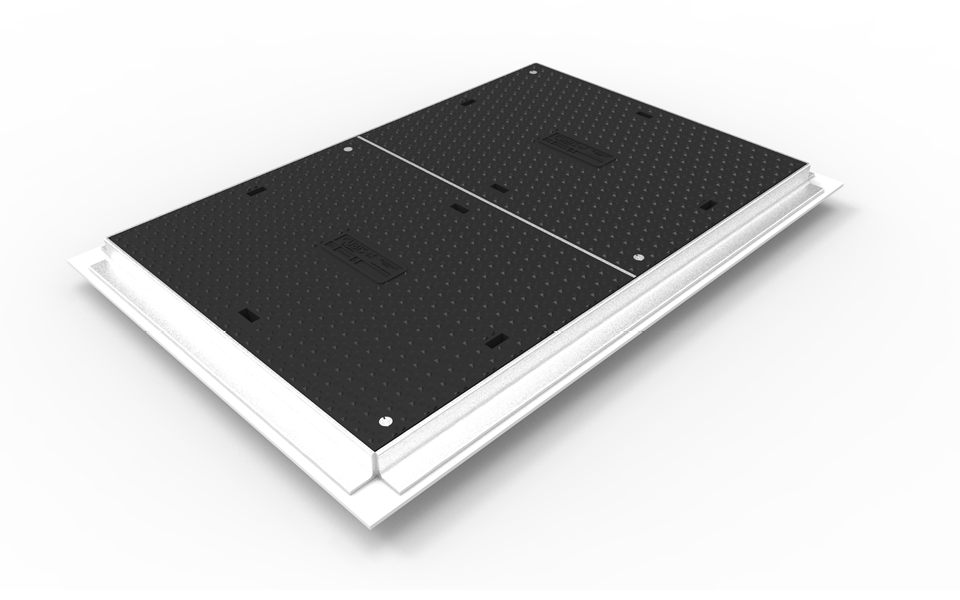

STAKKAbox™ ULTIMA Connect, AX-S™ Composite Cover

Sector

Rail

Case Study

The Cubis STAKKAbox™ ULTIMA Connect chamber provided SEPTA with an outstanding combination of durability, customisation, and ease of installation for protecting sensitive railway components.

Project Challenges

Commuter rail lines in densely populated areas rely on intricate communications and signaling systems for efficient and safe operations. The infrastructure that protects those systems must be durable, reliable, and easy to configure for ongoing upgrades.

The Southeastern Pennsylvania Transportation System (SEPTA) was in search of an alternative to their existing polymer concrete chambers to support the need to add capacity to the system (including additional fiber cables). In the Philadelphia area typically polymer concrete boxes are used along with cable trench and ducting to protect transit signal and communications wiring.

The standard polymer concrete boxes are difficult to modify without compromising strength, especially when a large number of ducts must interface in a single chamber. SEPTA needed a solution that could accommodate a higher quantity of 150mm holes (cored-out duct access holes or square cut-outs in the field) while maintaining the structural integrity of the access chamber.

Cubis Solution

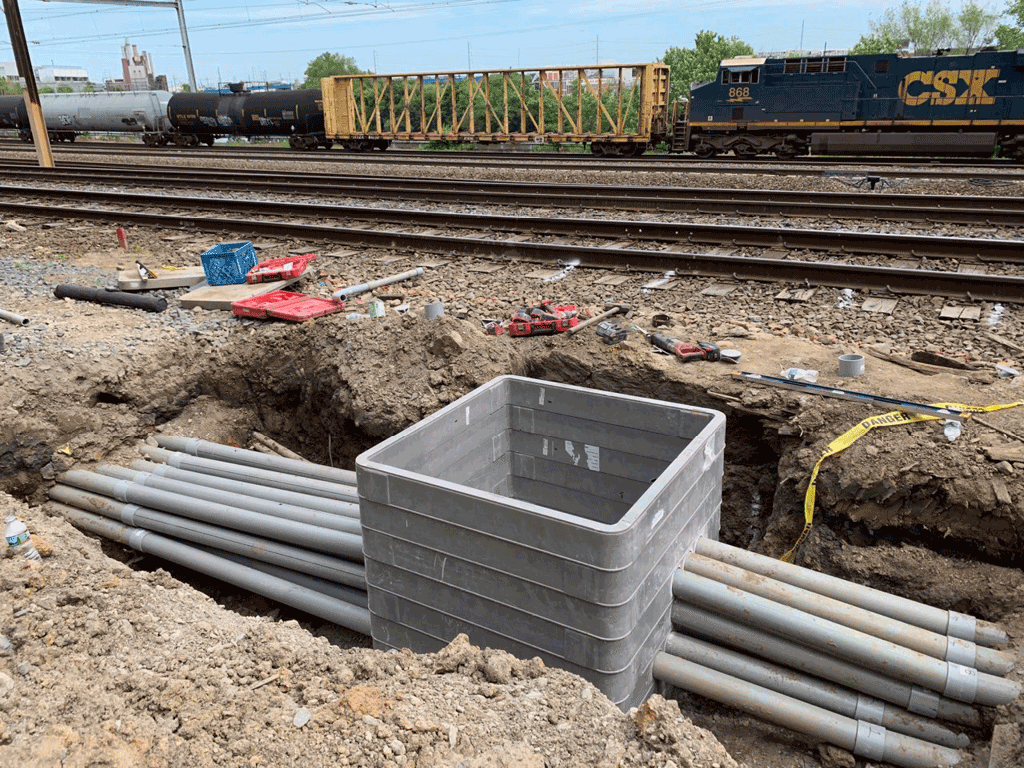

Cubis provided SEPTA with one 1000mm x 1000mm x 1000mm ULTIMA Connect with steel frame and AX-S™ Composite Covers, configured so the duct to chamber to vault transition holes could be drilled on site.

Installation was simple and straightforward:

- An excavator was used to dig a hole in the ground.

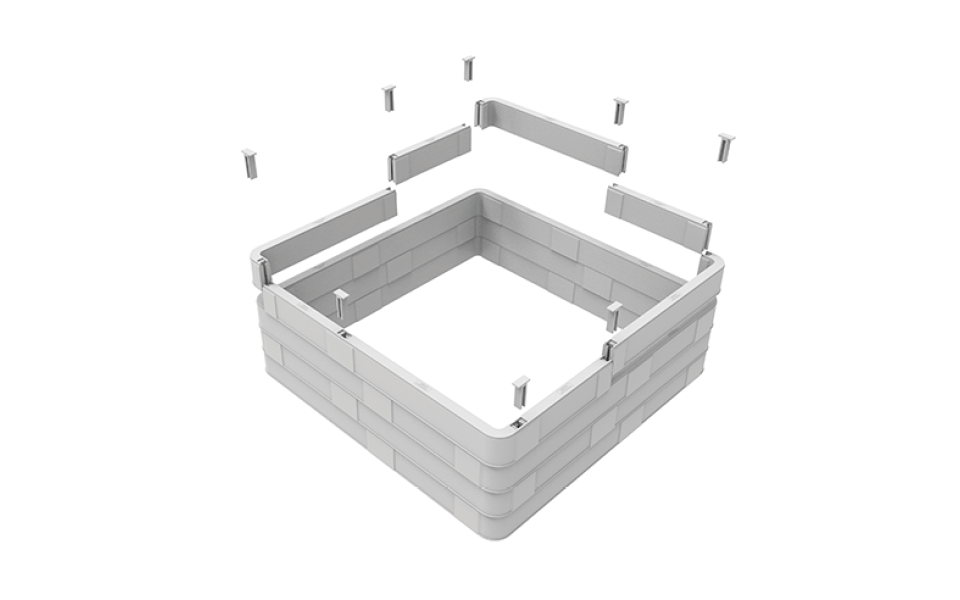

- The excavator then lifted and set half of the chamber (a total of 5 sections), followed by the balance (an additional 3 rings) to create an entirely assembled chamber. (Note: This configuration could also be built directly in the hole, one ring/layer at a time).

- Holes were drilled out on opposite sides of the chamber (15 on one side, 8 on the other) and ducting access extensions were inserted.

- The area around the chamber was backfilled.

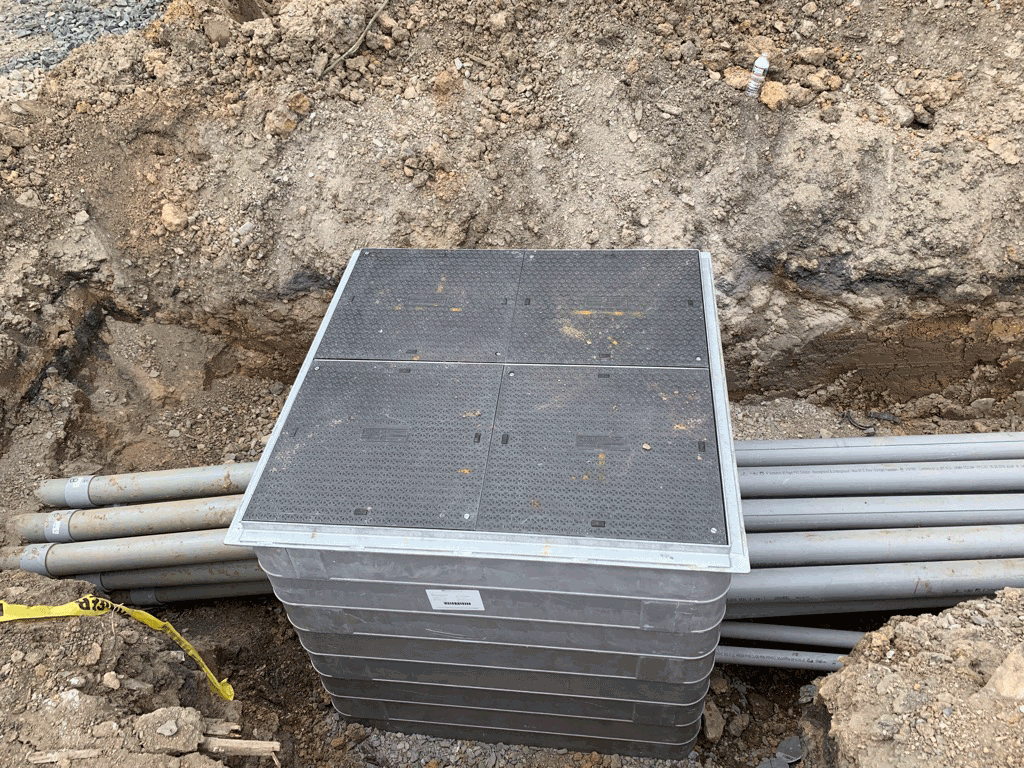

- The frame was placed on the body, and composite covers were secured to the frame with screws.

Total time for installation was approximately 3 hours.

Everyone was extremely impressed with the ease of installation and accessing the conduit through the body. - Cort MacLean, Transit Account Manager

The Cubis ULTIMA Connect chamber proved an outstanding solution for SEPTA requirements:

- Openings for cable trench or ducting can be prefabricated or cut on site without compromising the chamber’s strength and performance.

- Rings can be added or removed to reach a customised final depth as dictated by the site conditions, due to the ULTIMA’s innovative layered design.

- The Glass Reinforced Polyester Resin (GRP) components offer more durability and will not crack when placed closed to vibrating rails.

- The body components and covers are lightweight, making it safer for the personnel installing the cables and providing easier access to the cables in the future.

Gold Standard Durability: The ‘Track Test’

After all tests, the Cubis ULTIMA connect Chamber met all form and function requirements. In fact, no sidewall flexure was observed in the chamber even with 150mm diameter holes cut on one side for ducting access. The box was left in a SEPTA main maintenance way next to the rail and will undergo a performance review for a period of 3-6 months.

The installation crew was extremely impressed with the ease of installing the chamber and accessing the ducting through the body. A second unit (ULTIMA Connect chamber) is scheduled to be installed within the next few months.