STAKKAbox™ Hydrant

The STAKKAbox™ Hydrant range has been specifically developed for the water market to house hydrant valves, air and sluice valves, metres, and washout chambers. The Hydrant chamber system has been designed to significantly reduce the costs of installations through time savings. Due to their twinwall design, individual sections are lightweight, meaning they can be easily stacked on top of each other to reach the specified depth with flexibility onsite with hand tools. The Hydrant system offers an effective replacement for concrete sectional chambers that don't break when dropped.

Features & Benefits

Fast and Easy to Install

STAKKAbox™ chambers are significantly faster to install than conventional alternatives, with complete installations typically taking less than one hour, resulting in reduced costs for the installer.

Flexible During Installation

Chambers can be adapted to suit on-site conditions with standard tools to overbuild over existing networks, Introduce duct entries for cable entry and for top-section fine adjustment.

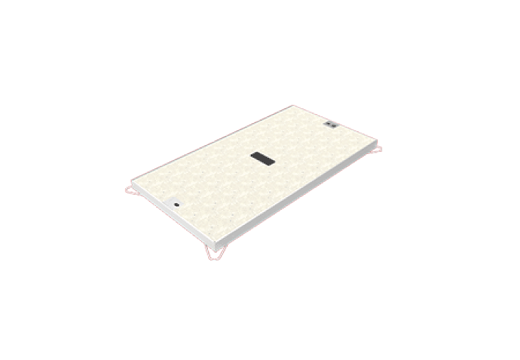

Sectional & Twin Wall Design

Chambers are built to required depth by adding 25mm or 75mm stackable sections. Due to the twinwall design, individual sections are light meaning that entire chambers can be manually lifted. Each access chamber possesses vertical and horizontal ribs, resulting in a product that is strong vertically and on the sidewall.

Manufactured from Recycled Material

Specifying STAKKAbox™ Hydrant helps end users reach sustainability targets due to the material being largely composed of high-grade recycled material. In addition, Hydrant is completely recyclable at the end of its life.

Complete System Offering

Can be supplied with D400 surface box or B125 Concrete Infill access cover.

Robust Material

No breakages and therefore lost product when in use and in transit.

Smooth Outer Walls with Lip to ‘Key In’

Gaps in the outer wall will negatively impact the effectiveness of compaction around the chamber. STAKKAbox™ chambers have smooth outer walls and an outer lip which keys into the backfill.

Material

STAKKAbox™ Modula from Polypropylene (PP) which possesses excellent strength to weight properties.

How it's Built

As part of our STAKKAbox™ range of preformed access chambers, the system is easy for one person to lift and is strong, supporting a minimum of 40 tonnes vertical loading. Each chamber section locks with the section above and below it, which provides exceptional sidewall stiffness. The STAKKAbox™ chamber can be installed in less than 20 minutes, meaning footways and roads can be re-opened quickly.

Materials

The STAKKAbox™ Hydrant chamber system is moulded from Polypropylene (PP) which possesses excellent strength to weight properties. Each section is ribbed internally to improve loading performance.

Available Sizes

STAKKAbox™ Hydrant chambers are formed by combining interconnecting ring sections with either a 25mm or 75mm profile in order to achieve the correct depth. Hydrant is available in two clear opening sizes and can be fitted with an LDPE base in a number of options.

Download our product size guide for chambers in order to gain more information on available sizes.

Load Rating

STAKKAbox™ Hydrant has been extensively tested to ensure that it meets the loading requirements up to D400 in a variety of installation environments.

The loadings match the vertical loading categories recognized by EN124 gully tops and access tops for vehicular and pedestrian users.