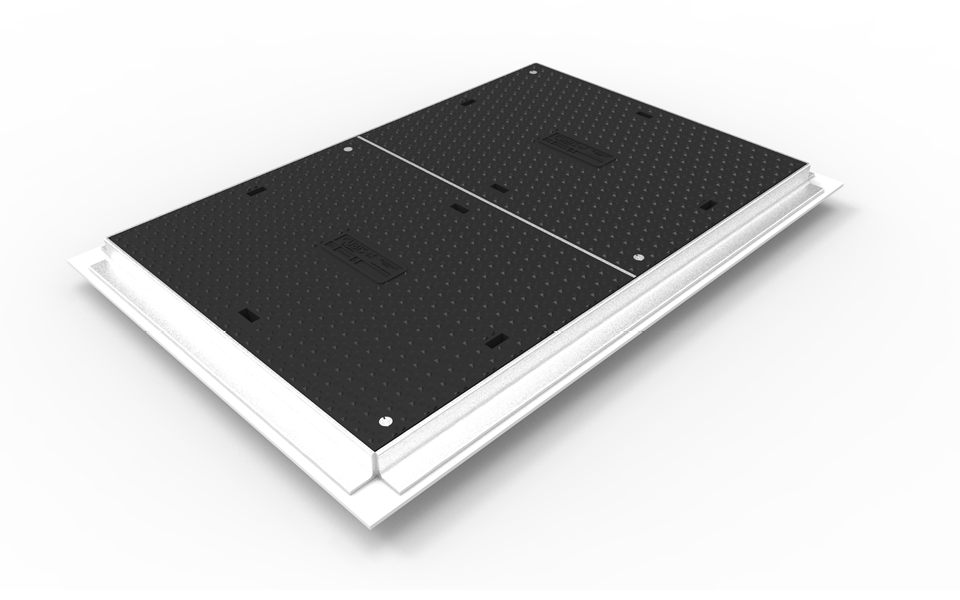

STAKKAbox™ ULTIMA

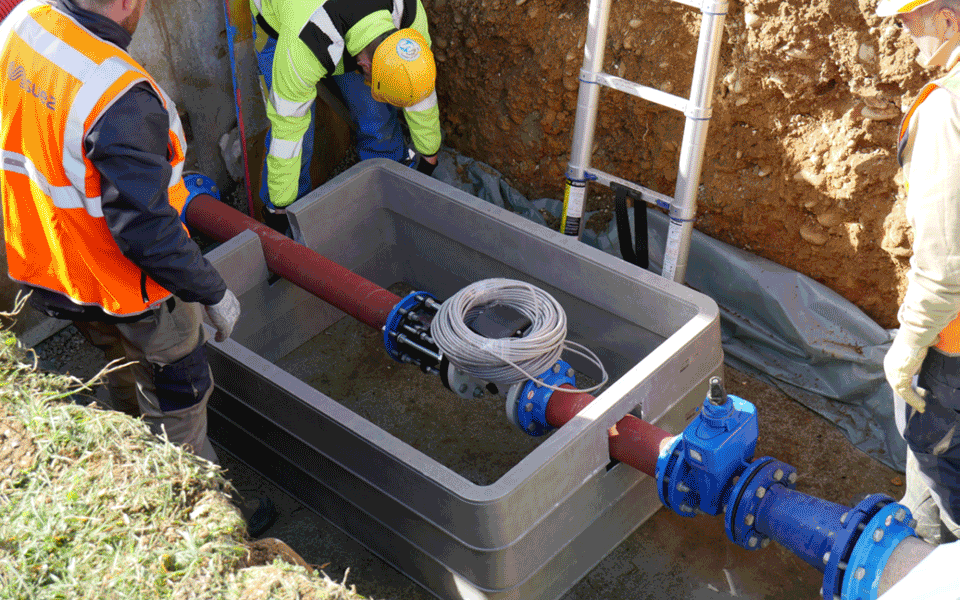

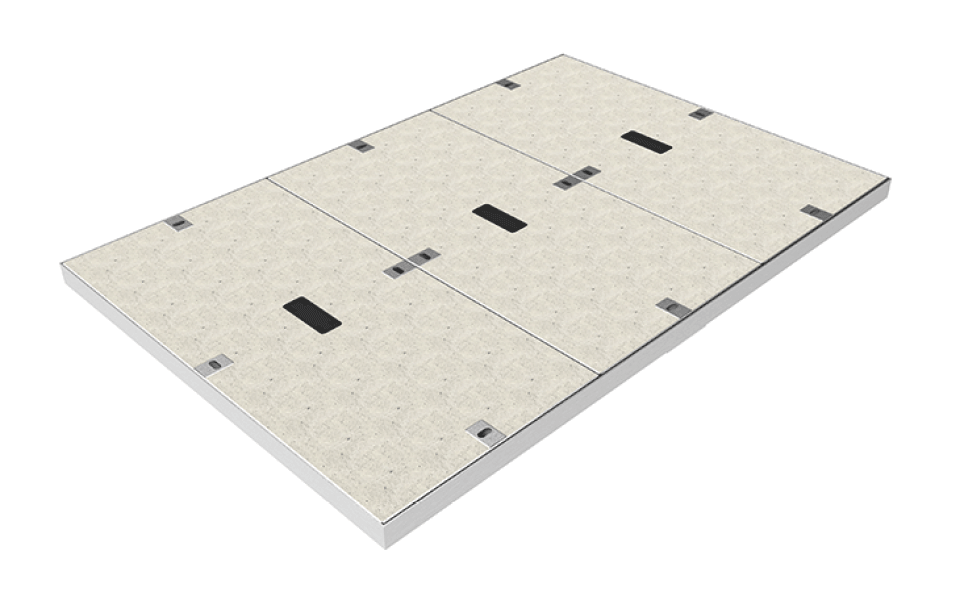

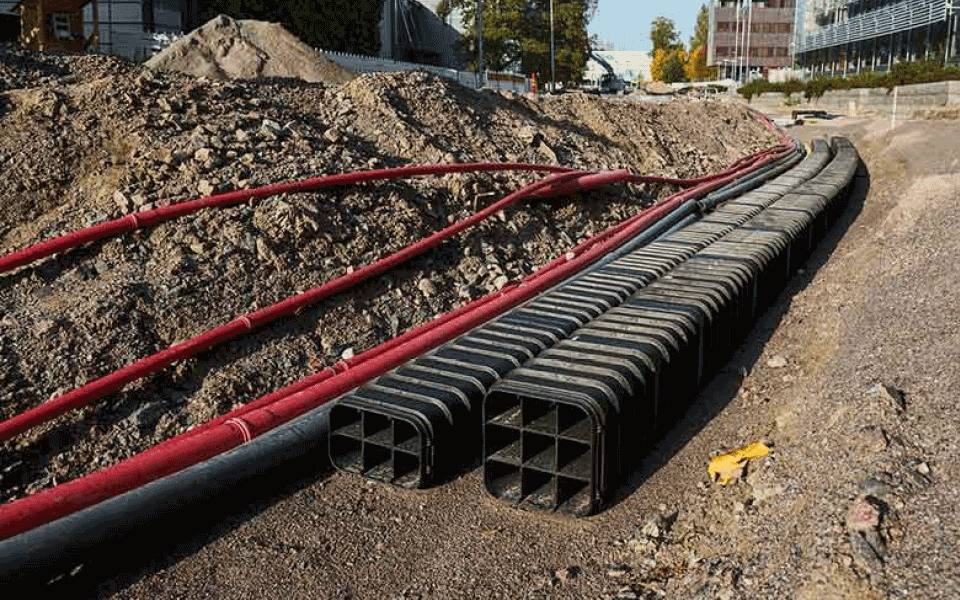

STAKKAbox™ ULTIMA offers a flexible access chamber system without compromising on strength. Due to its design and the material used (GRP), the ULTIMA chamber can be used anywhere where side wall loading is a concern, such as highways or railway tracks. Its range of accessories and access cover options makes it the most versatile solid ring chamber system that can meet F900 loadings.

Features & Benefits

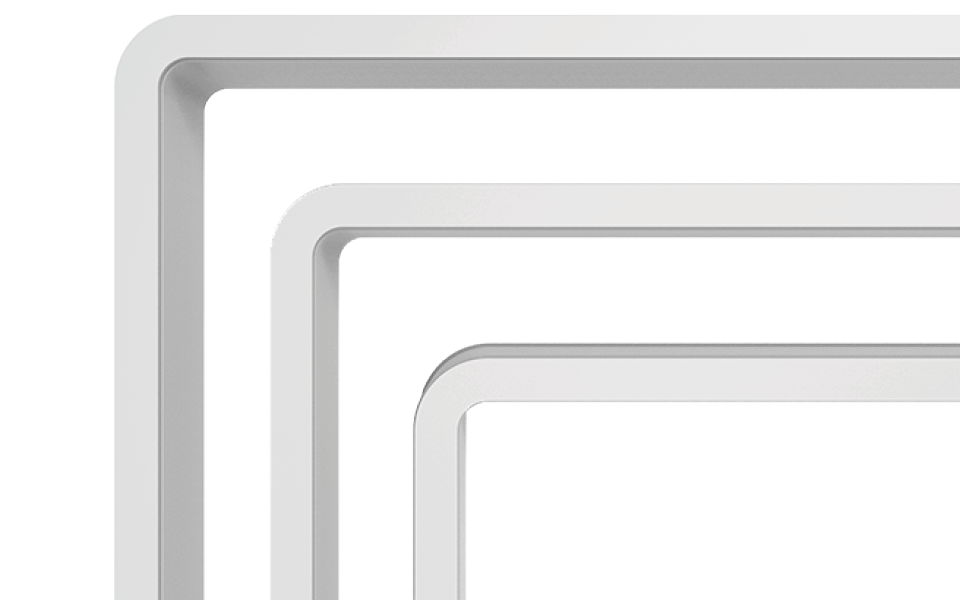

Variability in Size

ULTIMA chamber sizes have been designed to be reflective of the most commonly used access chamber sizes. This makes ULTIMA the ideal retrofit solution for existing networks, minimising site disruption and installation costs.

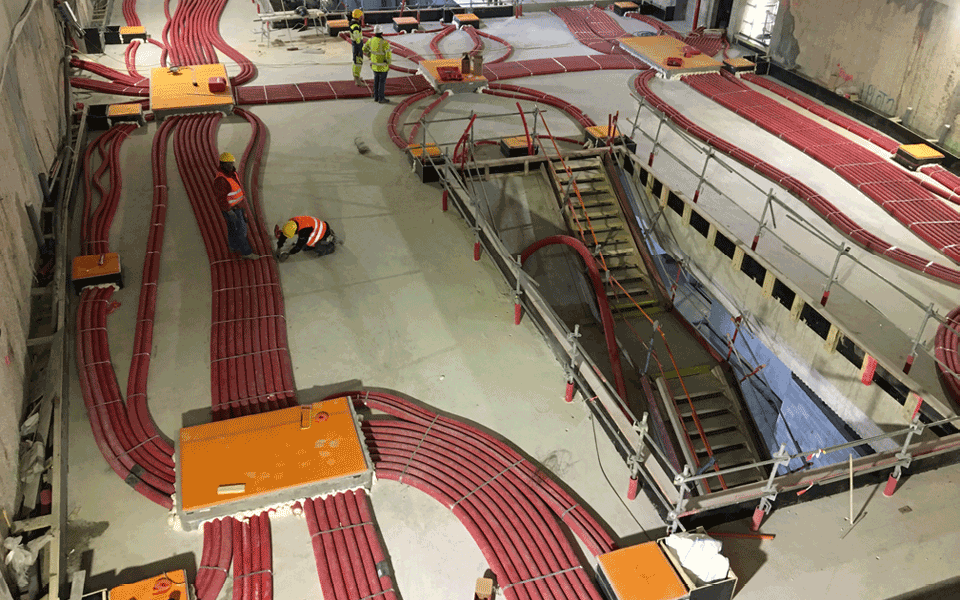

Fast and Easy to Install

STAKKAbox™ chambers are significantly faster to install than conventional alternatives, with complete installations typically taking up to one hour. This results in reduced costs for the installer. Only the largest sizes in the range require specialist equipment or plant in order to install the chamber.

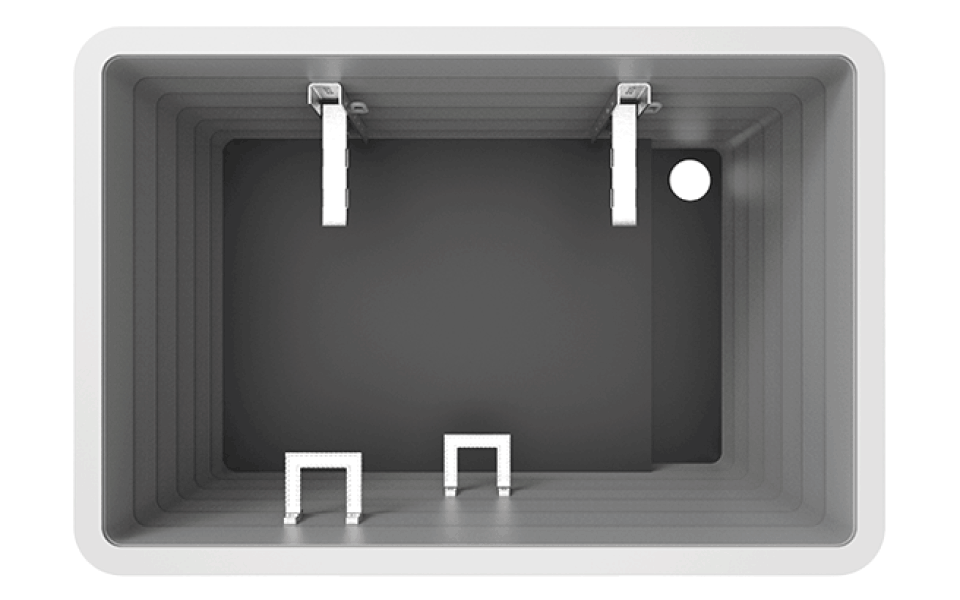

Flexible During Installation

Chambers can be adapted to suit on-site conditions with standard tools to overbuild over existing networks, Introduce duct entries for cable entry and for top-section fine adjustment

Fire Retardancy

ULTIMA won't catch fire and has low smoke properties. This means the product can be used in enclosed areas such as tunnels and underground transport.

Smooth Outer Walls with Lip to ‘Key In’

Gaps in the outer wall will negatively impact the effectiveness of compaction around the chamber. STAKKAbox™ chambers have smooth outer walls and an outer lip which keys into the backfill.

High Strength to Weight Ratio

The material is significantly lighter than other conventional materials that can provide the same inherent strength.

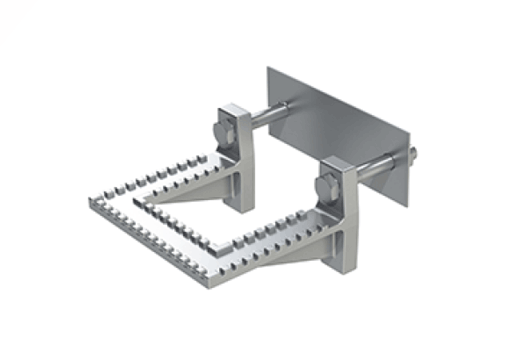

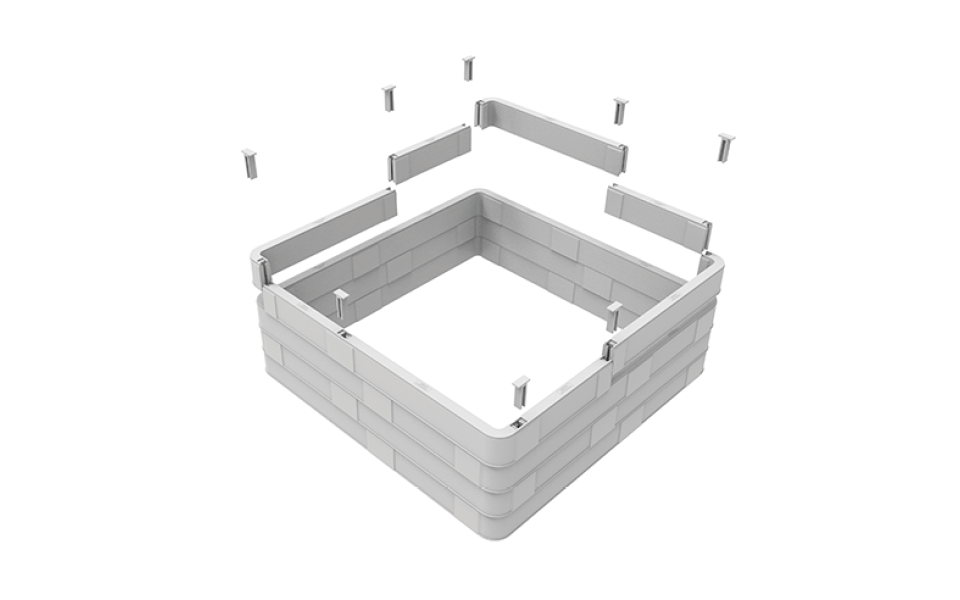

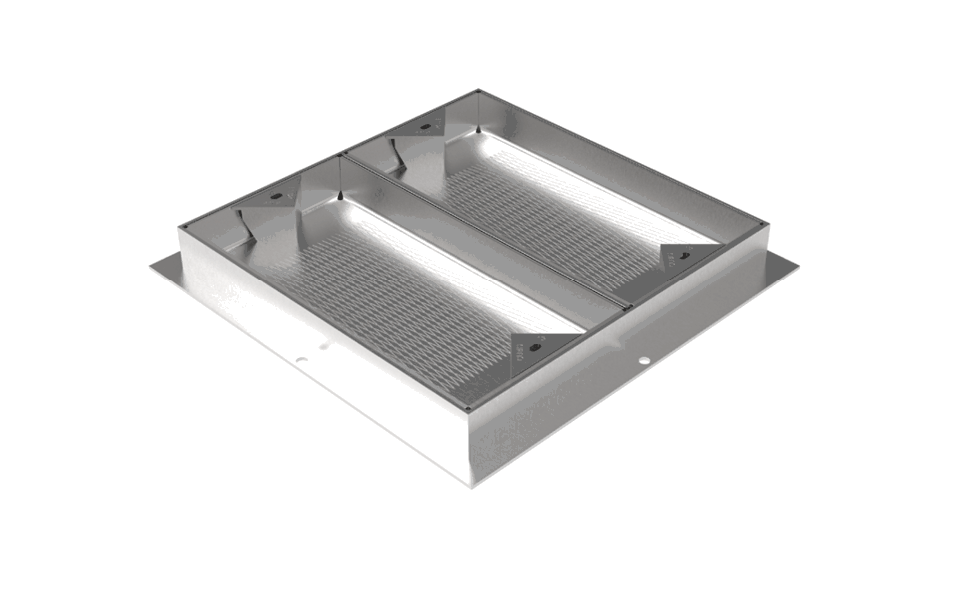

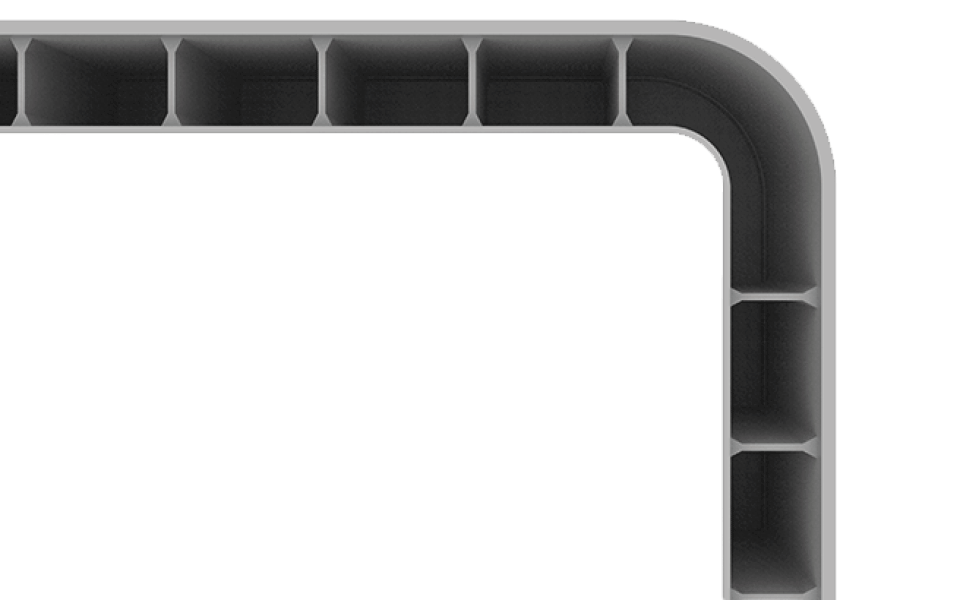

Sectional & Twin Wall Design

Chambers are built to required depth by adding 150mm sections. Due to the twin wall design, individual sections are light meaning they can be manually lifted. Each access chamber possesses vertical and horizontal ribs, resulting in a product that is strong vertically and on the sidewall. For most applications, ULTIMA doesn’t require specialist backfills, reducing installation costs.

How it's Built

ULTIMA chambers are constructed by stacking 150mm deep ring sections to reach the desired height. Each ring section is castellated to positively interlock with the units above and below. Due to the sectional twinwall design and the GRP material, most ULTIMA 150mm deep sections fall under 25kg in weight, making them suitable for a single person lift under manual handling regulations.

Materials

Manufactured from Glass Reinforced Polyester Resin (GRP) material for long-lasting toughness, durability, and strength.

ULTIMA chambers can achieve and exceed F900 vertical load test results. Side loads are comparable to that of concrete chambers, with the added benefit of being twin walled complete with both horizontal and vertical ribs.

Available Sizes

ULTIMA chamber sizes have been designed to be reflective of the most commonly used access chamber sizes. This makes ULTIMA the ideal retrofit solution for existing networks, minimising site disruption and installation costs.

Download our product size guide for chambers in order to get more information on available sizes and see our STAKKAbox™ ULTIMA Connect chamber solution, which can be scaled to any size you require.

Load Rating

STAKKAbox™ ULTIMA is suitable for meeting and exceeding installation environments rated to F900 under EN124.

Ideal for areas imposing high wheel loads, such as docks and airfields whilst still enabling adaptability to varying underground utilities.