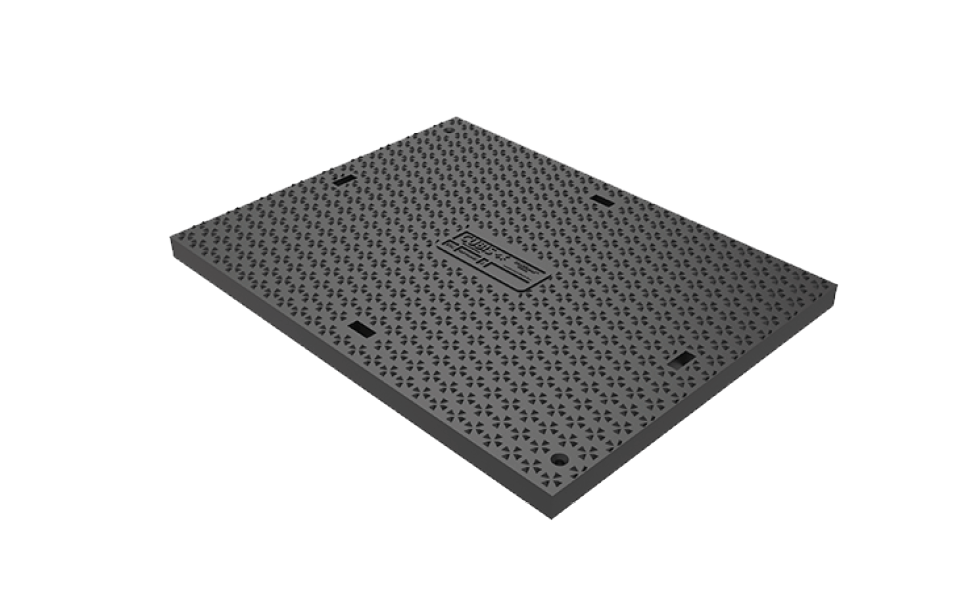

Composite Cover

Composite covers offer a lightweight cover with no reduction in loading performance. A wide range of sizes can be manufactured utilising multi-cover frames and there are options for bespoke customer badging.

Features & Benefits

Bespoke Sizes Available

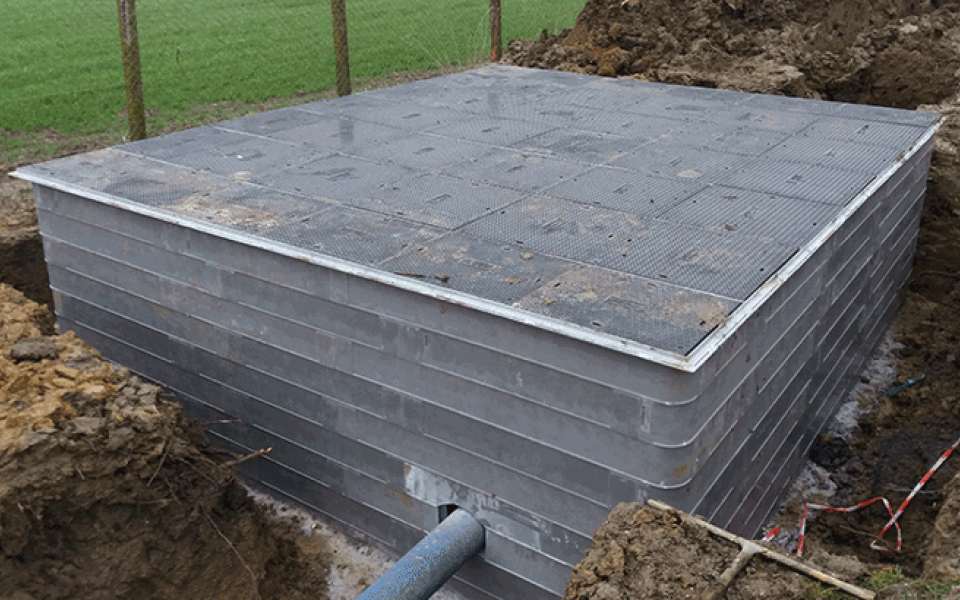

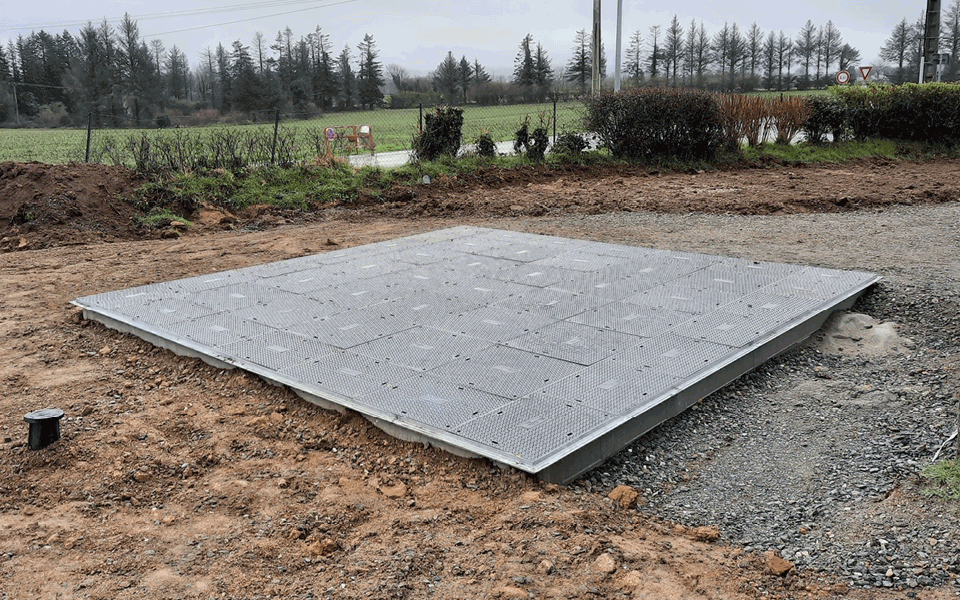

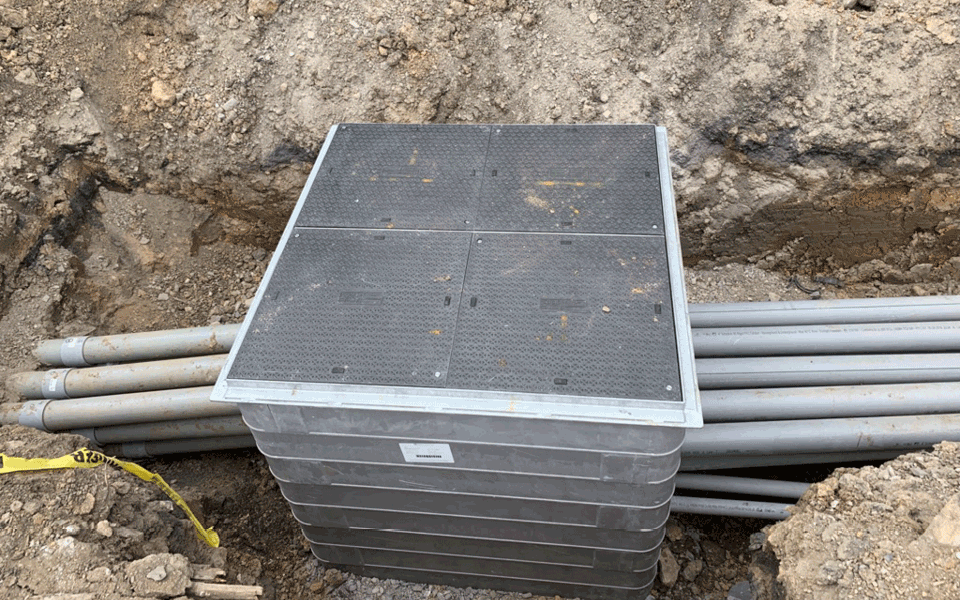

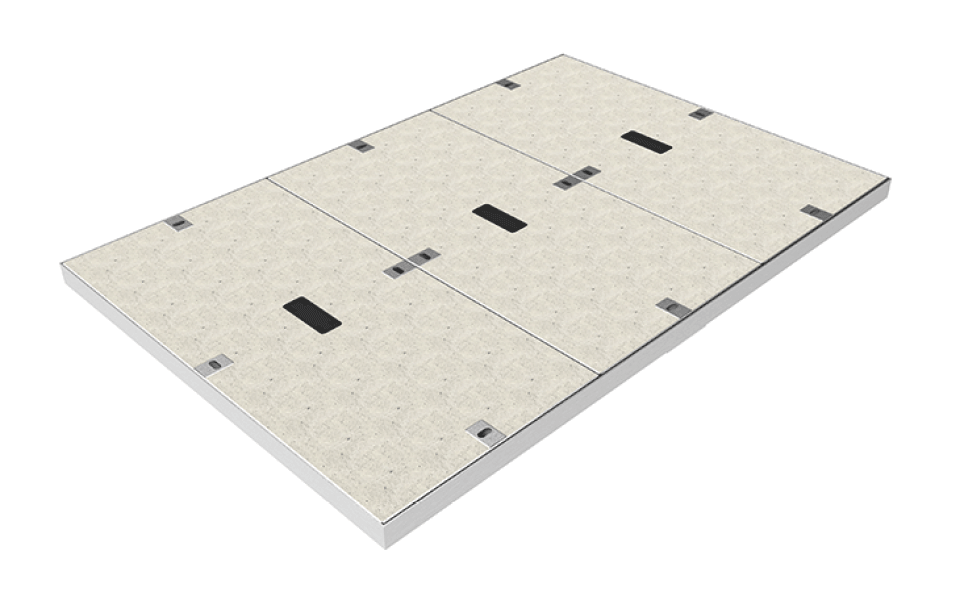

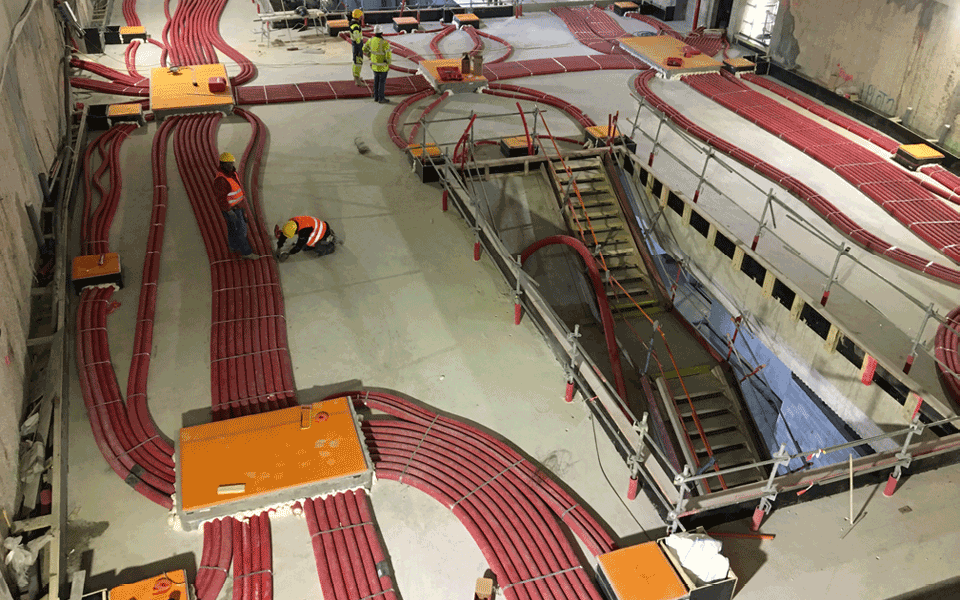

Can be manufactured in a large size range, using cross-beams and cross-pieces to build multi-cover units.

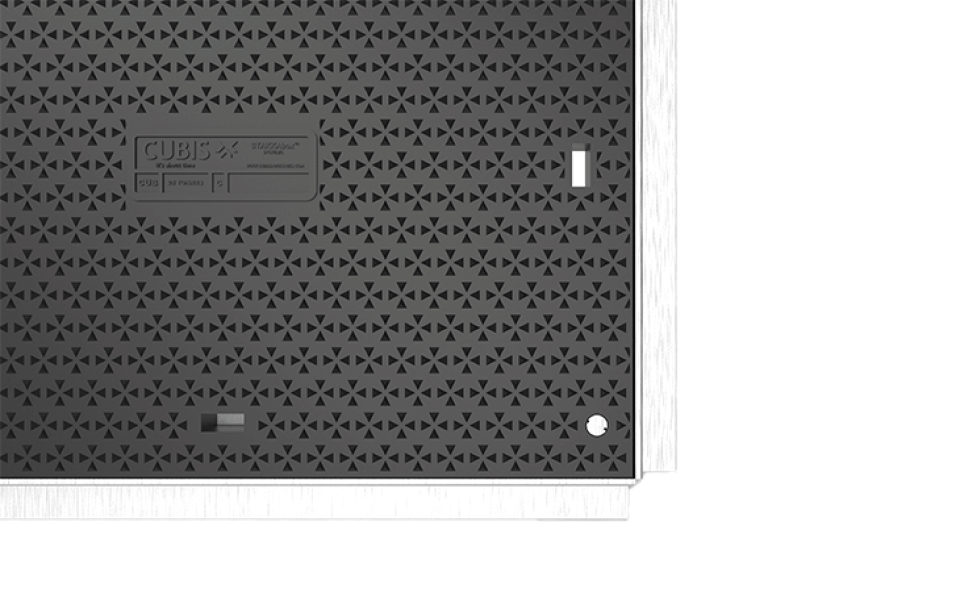

Badged with Customer Information

Covers can be badged with information to allow for identification by operatives.

No Inherent Scrap Value

Covers are not attractive to thieves. Stolen covers mean costs of replacement and of guarding open access chambers.

Long Lifespan

Composite access covers have long service life when installed, providing lower total life costs for the end user.

Anti-Slip Design

The tread pattern on the cover is non-slip, exceeding a Slip Resistance Value (SRV) of 80.

Lightweight

Composite access covers weigh less than 30kg, allowing the covers to be easily removed.

Locking Options

Composite access covers are fitted with bolt-down locking which can be specified to the end user’s requirements. This prevents access to the infrastructure network below.

Permeable to Radio Waves

Composite access covers do not block radio waves, allowing telemetry readings to be taken without removing the access cover.

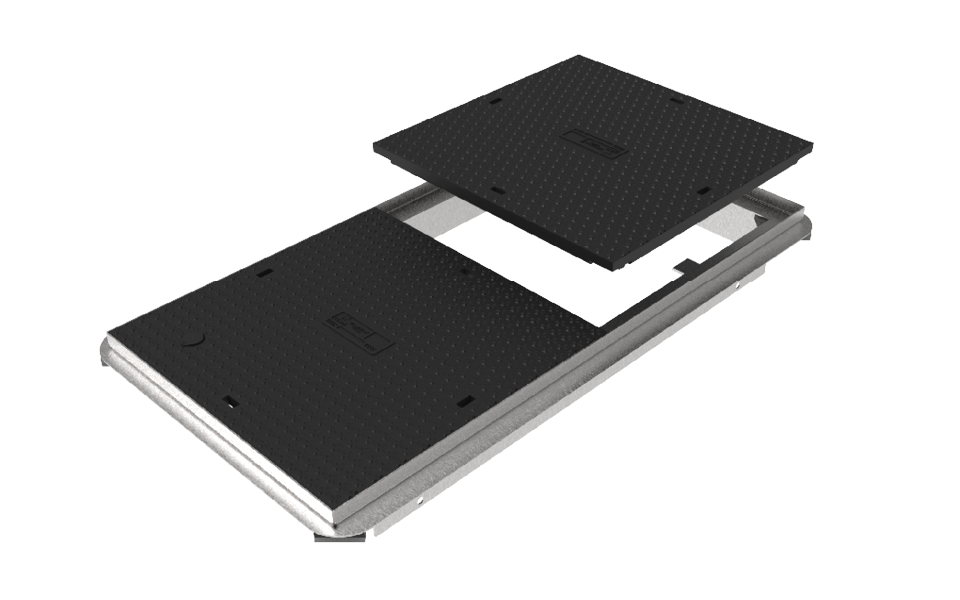

How it Works

A suitable frame with additional cross pieces (where applicable) are fitted to the chamber top. The Composite cover(s) are then placed carefully into the frame. Grommets are added in the lifting points and the cover secured using supplied screws.

Materials

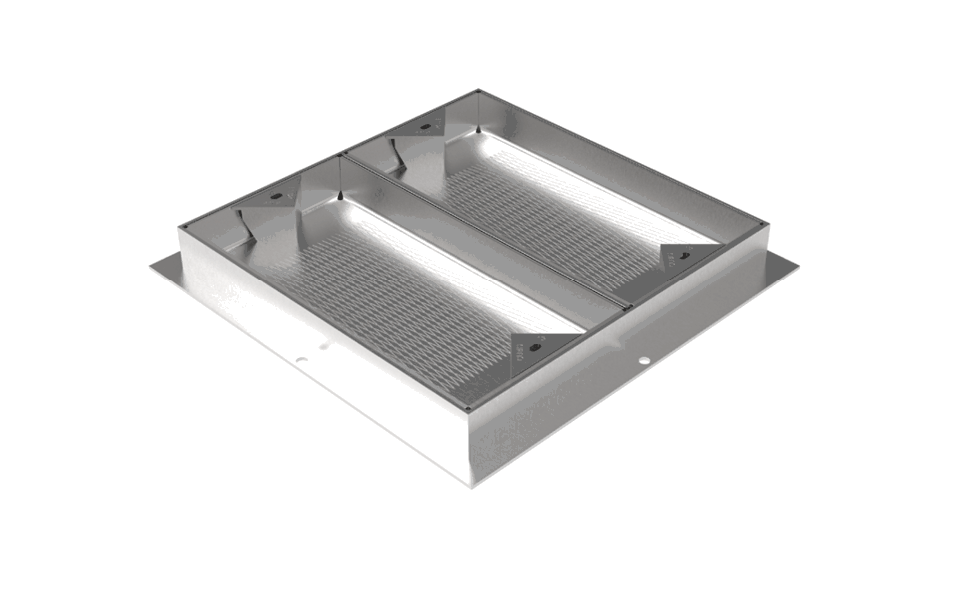

Rolled Steel & GRP

The frames, covers and cross pieces are manufactured from rolled steel section in compliance with BS1449 and galvanised in compliance with BS EN ISO 1461. Covers are manufactured from Glass Reinforced Polyester Resin (GRP). 'A' rated covers are manufactured from BMC (Bulk Moulding Compound). 'B' and 'C' rated covers are manufactured from SMC (Sheet Moulding Compound).

Available Sizes

Composite covers are available in a range of standard sizes as well as available as bespoke covers using cross-beams and cross-pieces to build multi-cover units with options in security and badging.

Load Rating

Composite covers meet the vertical load classes of A15, B125 and C250 set by EN124.

A15: Suitable for: pedestrians only areas B125: Suitable for: footways, pedestrian areas and comparable areas, car parks or parking decks. C250: Suitable for: kerbside channels