PROtrough selected globally by contractors looking for smart, time-efficient and sustainable solutions.

Case Study Details

Client

Evolent AB

Location

Mora, Sweden

Product

PROtrough

Sector

Rail

Case Study

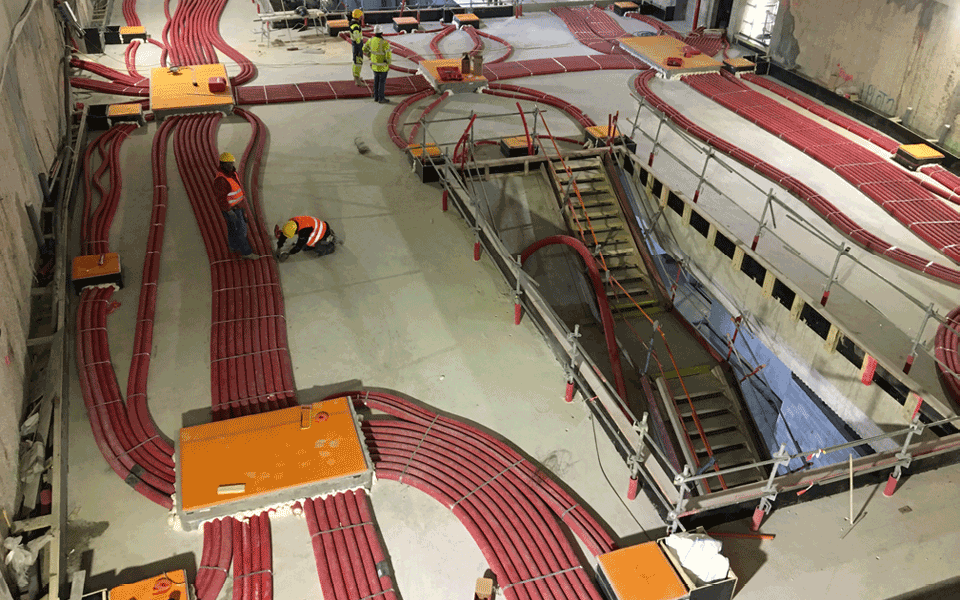

With over 100 years of experience in consulting and contracting, Swedish company Evolent AB looks to partner with companies who share their same values of working sustainably, managing tight project deadlines and minimising costs. In Mora, Sweden, Cubis Systems’ partner Melbye (working in Sweden, Denmark and Norway) collaborated with Evolent AB to provide advanced infrastructure solutions for a complex bridge application.

Tobias Göransson, one of the main project managers, stated that the railway upgrade project was initiated to, “control the train traffic through Mora remotely, instead of using local control systems.” To achieve what they had set out to do, the project would involve installing new trackside troughing for electricity, IT, telecommunications, and signalling.

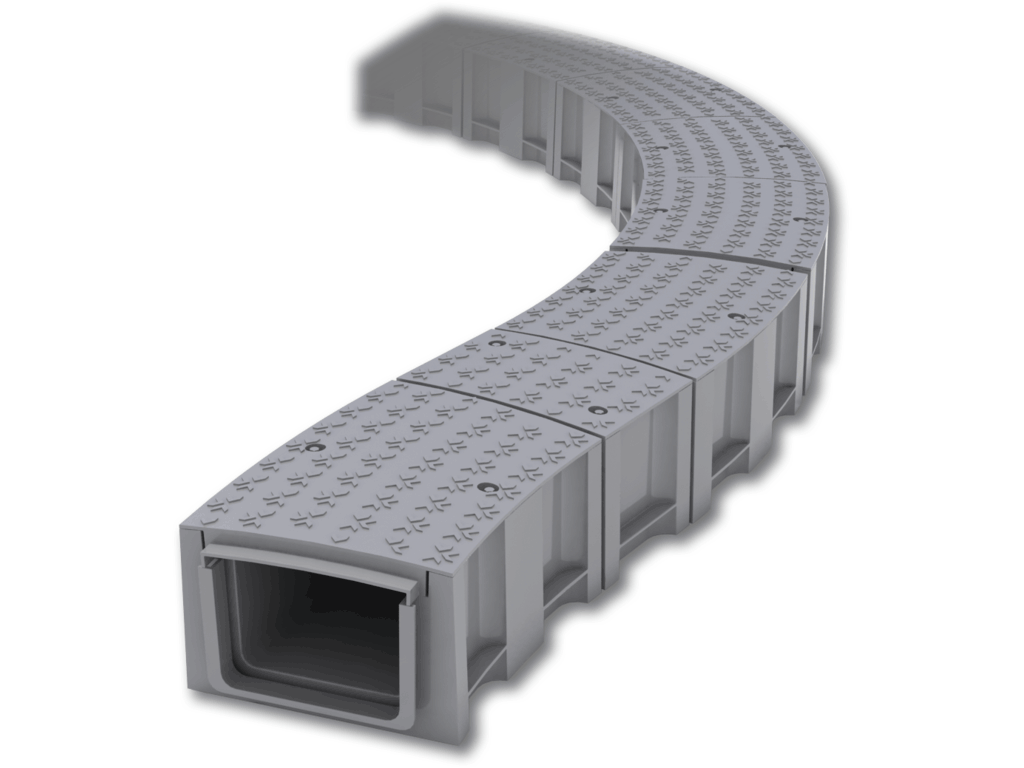

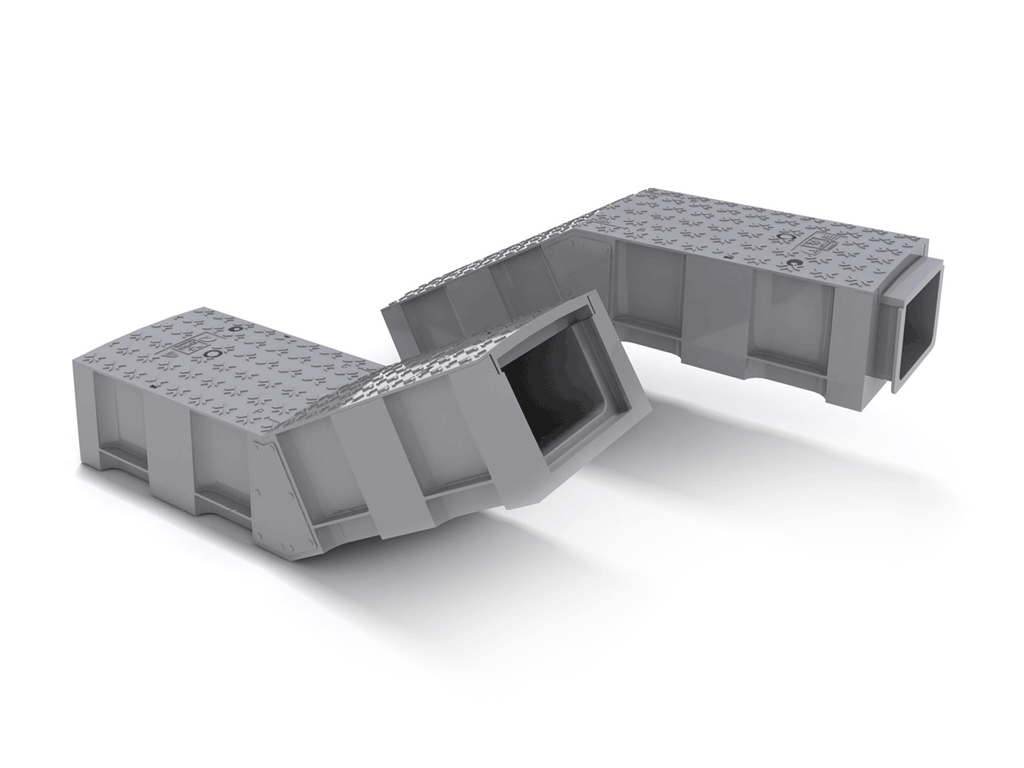

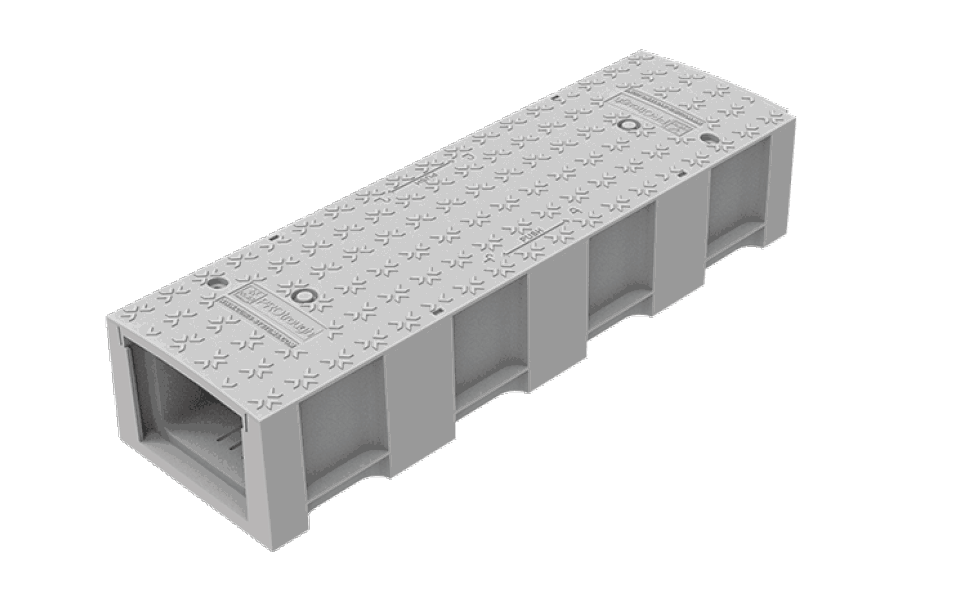

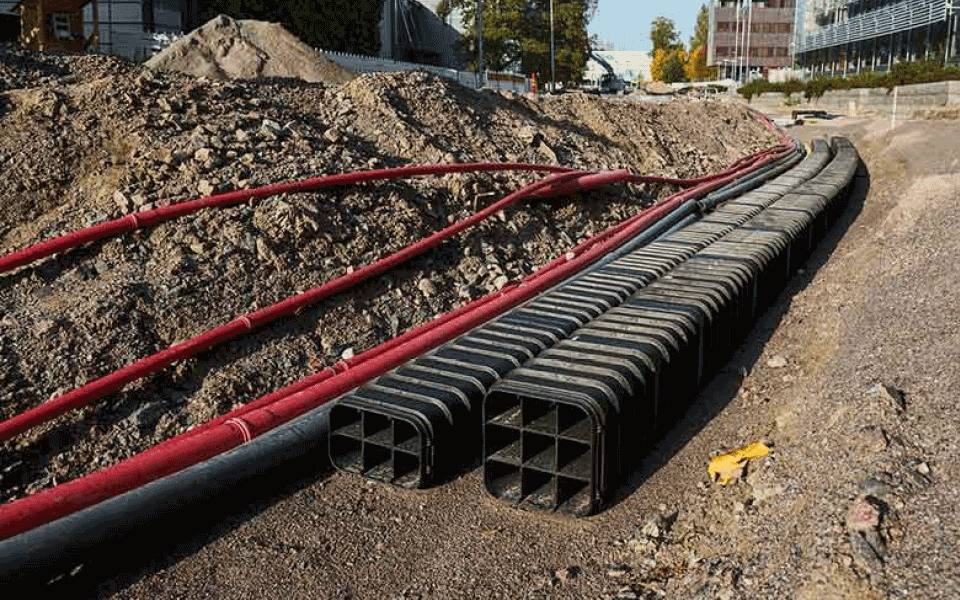

When the project was assigned to Evolent AB, Melbye quickly highlighted Cubis’ PROtrough as the ideal product for the Swedish Transport Administration’s railway upgrade. PROtrough is made of fiberglass-reinforced plastic (GRP) and consists of lightweight, 1-meter-long sections that are easily assembled manually. This means that product handling is significantly smoother and more efficient than that of concrete cable trough alternatives.

In Mora, the team was impressed with how efficient the installation process was. “The lightweight, modular product has been very easy to handle, and it could even be placed on the inside of the bridge. It has really helped to facilitate the work with cable management” said Göransson.

With a weight of less than 20 kg, PROtrough provides significant health and safety benefits compared to traditional concrete troughing, which can easily weigh over 90 kg. PROtrough can even be lifted and installed by one person in accordance with the regulations for manual handling. The frame is easily assembled with interlocking connections. Also, the cover has a unique coupling protection which is easily connected thanks to a sliding mechanism and a click system.

For project Mora one of the biggest advantages of Cubis’ PROtrough was its adaptability. “Where traditional alternatives are often laid on the outside of the bridge, it was a big plus that PROtrough could be placed on the inside. This has resulted in a more efficient working time” commented Göransson. “By using a cable trough that can be laid on the inside of the bridge, we minimised the need for work platforms, and everything became more time effective. This also made our work easier for future projects because the cable trough is much easier to open when it is placed on the inside.”

Melbye had suggested Cubis’ products understanding they are able to perform regardless of the complexity of the project. Their collaborative approach and technical expertise meant that they could provide the most advanced solutions, engineered to accommodate for the unique challenges of project Mora.

Working directly with our customer, Melbye offered Cubis’ products to provide a safer, more sustainable, and more cost-effective solution. Do you have questions about PROtrough, or do you want to know more about our other concrete-free solutions? Please contact us! We help you find the best solutions and are happy to demonstrate our products. Alternatively, explore some of other other Case Studies.