MULTIduct™ offers innovative solution at new train depot in Feltham

Case Study Details

Client

South Western Railway

Location

Feltham, UK

Product

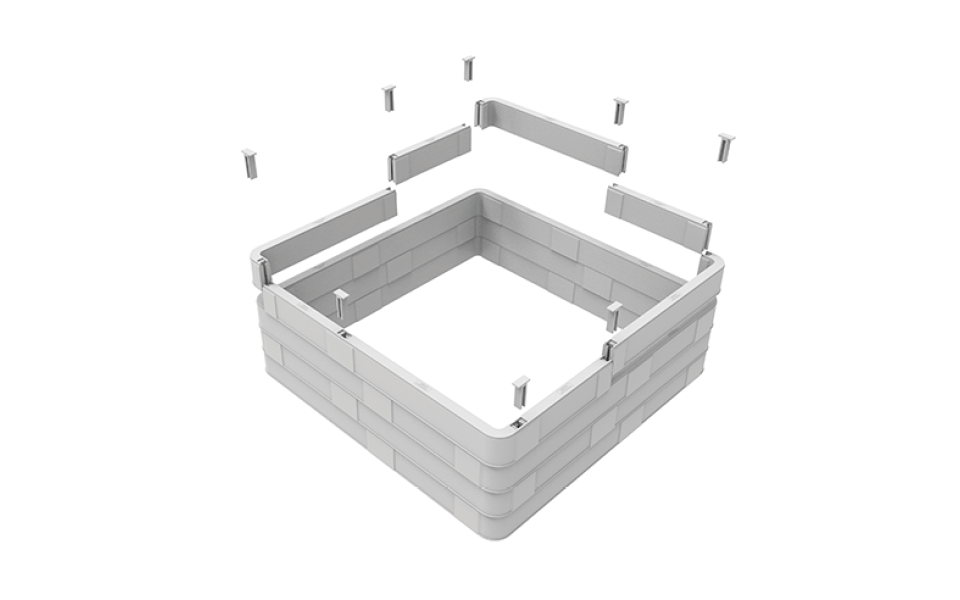

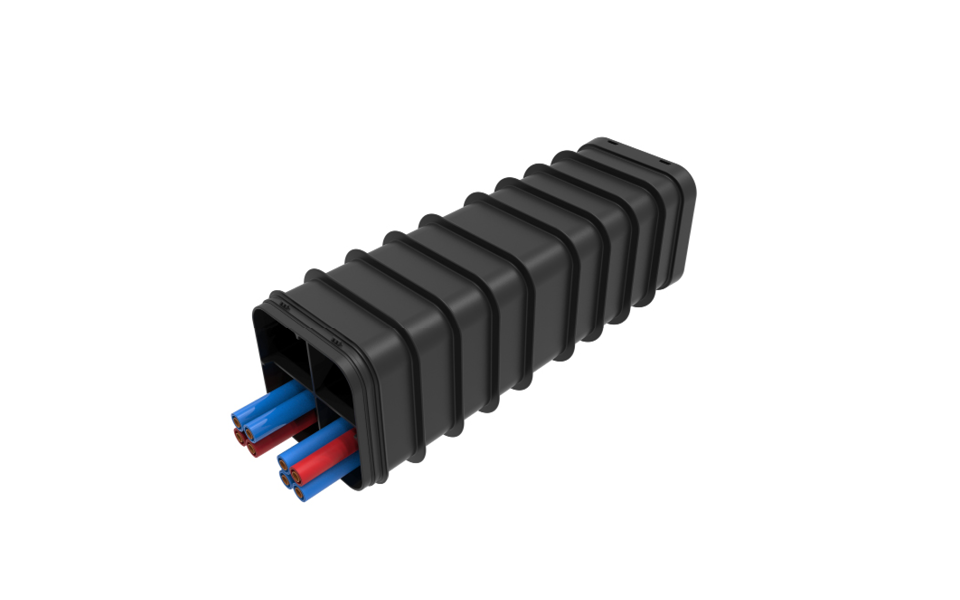

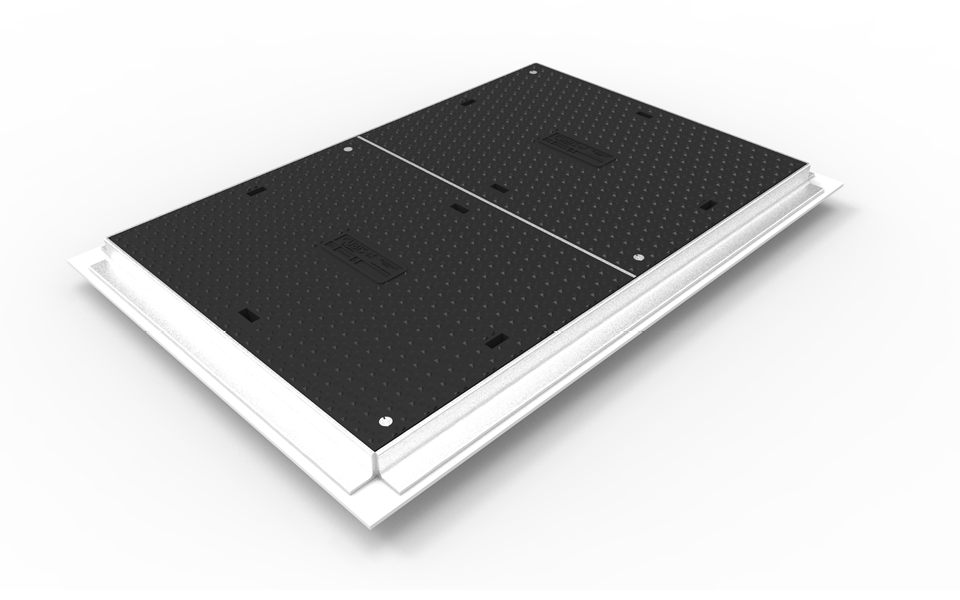

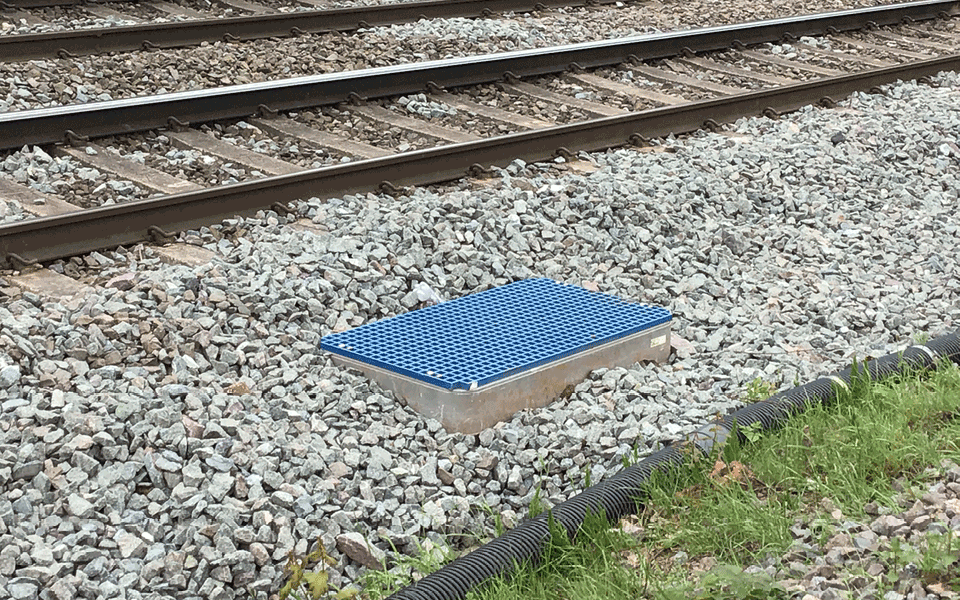

STAKKAbox™ ULTIMA Connect, MULTIduct™, AX-S™ Composite Cover

Sector

Rail

Case Study

Cubis Systems worked with the principal contractor, VolkerFitzpatrick and the design team at Arcadis to offer an innovative solution for the network access chambers and ducting system, on the brand new South Western Railways £60m flagship depot in Feltham.

The depot will not just be housing the trains but will also be used to maintain them both mechanically and for cleaning them both inside and out every night using specialised train washing facilities.

The new train depot will bring huge benefits of service reliability and frequency to those that need it most when commuting to and from the surrounding areas into central London.

The project has been designed to meet the highest level of standards expected by BREEAM and the services and products supplied by Cubis have gone towards achieving that standard. From value engineering the design to providing contractor-friendly and lightweight system solutions such as MULTIduct™ made from recycled material has helped at every stage.

Using MULTIduct™ in combination with the STAKKAbox™ ULTIMA Connect chambers enabled contractors to seamlessly integrate the systems with one another throughout the depot construction.

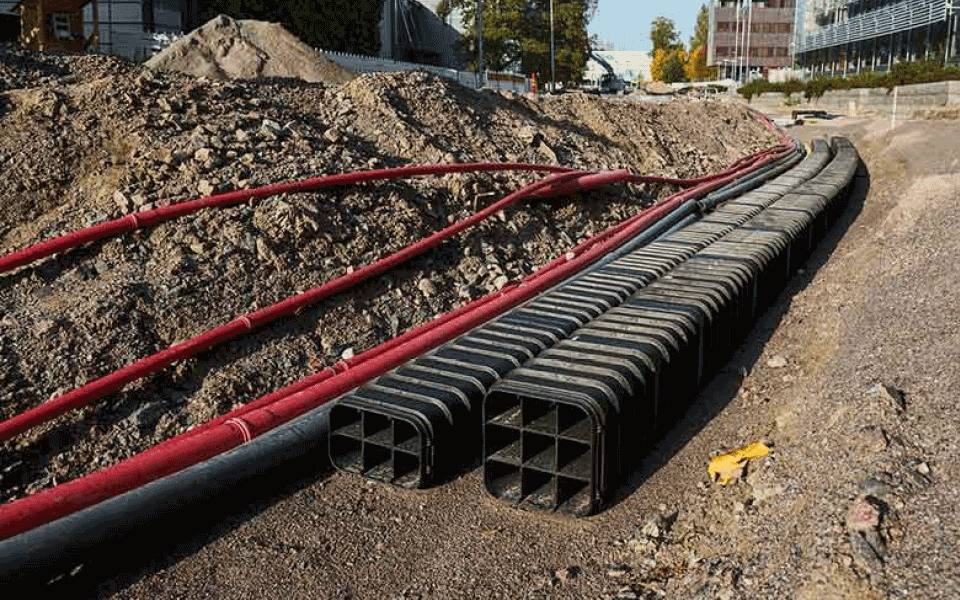

Cubis worked with the design team at Arcadis to use MULTIduct™ to its full potential, installing it with only 600mm of cover material. This reduced depth allowed for a shallower chamber to be used, resulting in a quicker installation of both ducting and chambers. By using these products together as a system Cubis removed the need for concrete as backfill for the GRP chambers or as a surround for the MULTIduct™ that would normally be used with other products.

Cubis offers carbon-friendly solutions by utilising 3rd party reviewed data gained from extensive testing. Cubis can also provide calculations to Eurocodes for verification and peace of mind.

These advantages were integral in creating the huge Under Track Crossing (UTX) across the 10 tracks that are going to stable the new fleet of 10 Car, Class 701 trains.

The overall reduction in excavation of material due to the shallower burial of the MULTIduct™ and network access chambers provided the contractor with an overall decrease in dig across the site. This lead to far less spoil removal, less excavator movements and fewer lorries moving to and from site.

This in turn provided a reduction in carbon emissions and disruption to the surrounding residential areas.