Built in Britain, trusted wordwide

Ready to specify for your next infrastructure project? Start with the best of British.

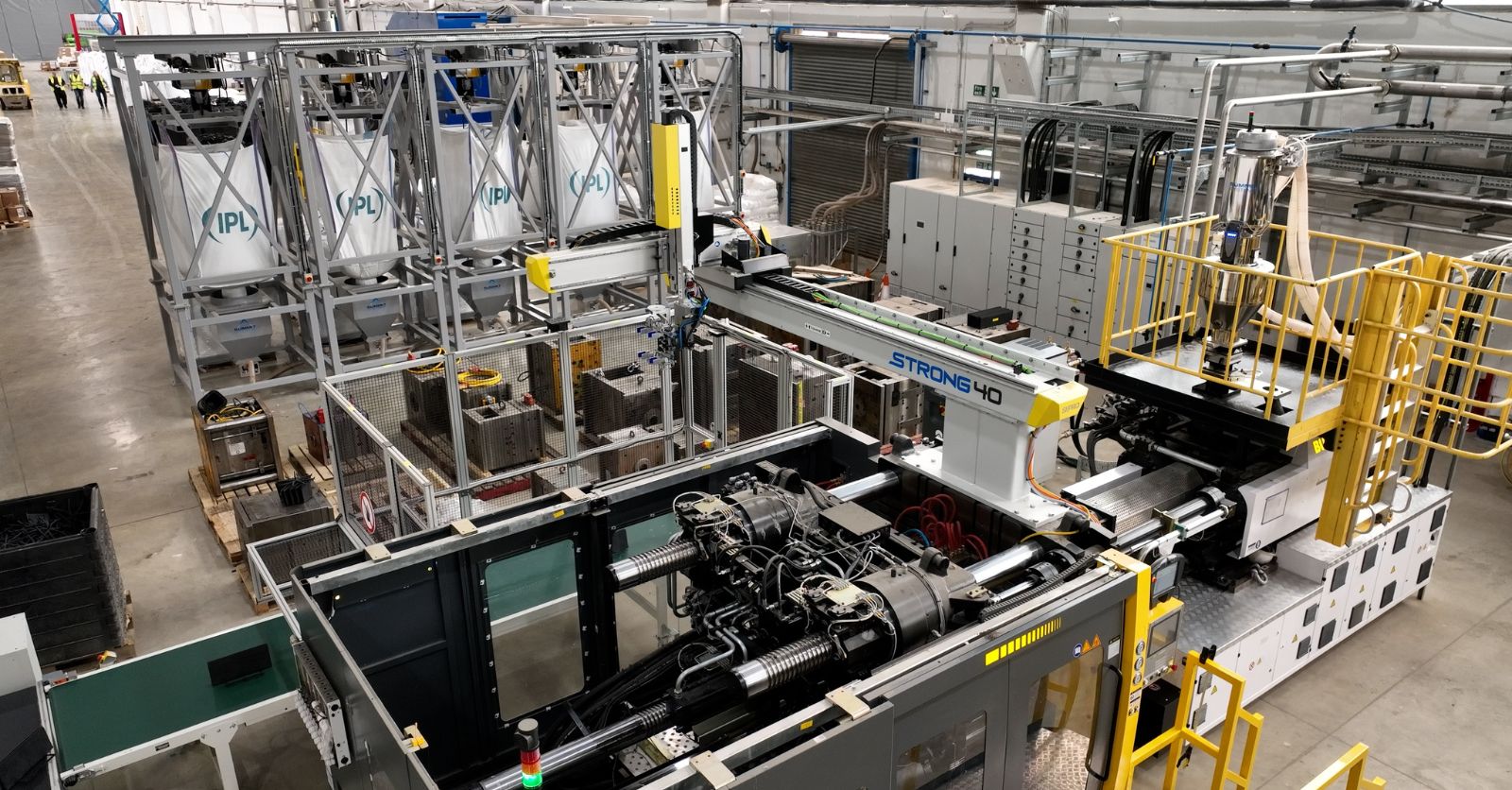

Cubis Systems manufacturing is proudly British. The “Made in Britain” logo you'll see on our products confirms you’re getting a piece of craftsmanship made in one of our five GB or Northern Ireland manufacturing facilities.

Why choosing a British manufacturer makes a difference

When you specify Cubis Systems, you're working with a manufacturer committed to delivering premium, UK-made products to support your underground infrastructure projects.

Our products are the sustainable alternative to traditional, carbon-intensive materials. They offer a carbon reduction of up to 80.7% compared to brick/mortar solutions.

But, as well as this inherent sustainability, you also gain clear green supply chain and project advantages by choosing a UK and Ireland manufacturer:

🚚 Reduced transport emissions and shorter logistics routes

🏗️ Faster delivery to site and improved programme certainty

🏭 Support for local jobs, skills, and supplier ecosystems

♻️ Lower embodied carbon vs imported heavy materials

📋 Compliance with UK safety, quality, and environmental regulations

✅ Approvals and endorsements from major UK utilities asset owners

🔎 Immediate, expert, and in-house testing and quality control at each site

🗺️ A mark of origin providing confidence in ethical sourcing and product quality

In short, Cubis Systems help you build faster, greener, and safer - all while supporting British manufacturing.

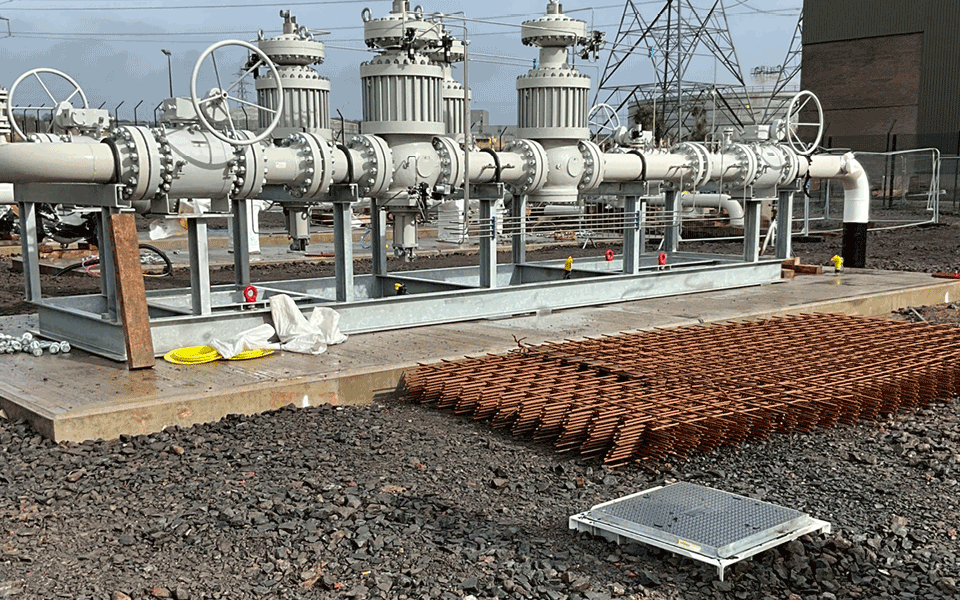

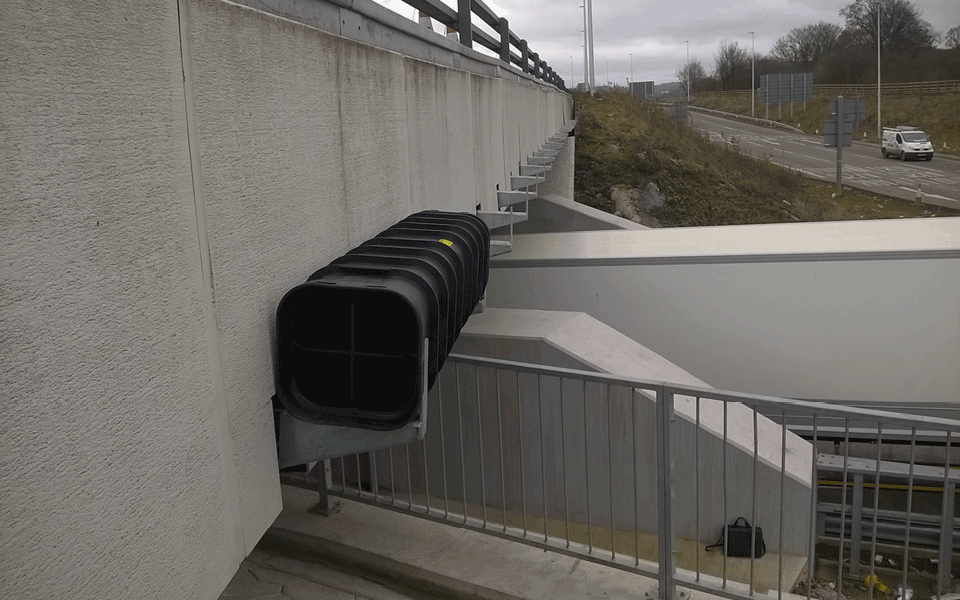

British-made systems for critical infrastructure

The "Made in Britain" mark spans our core product families, supporting critical networks across the UK and beyond. From our world-leading STAKKAbox™ range to our industry-changing cable troughing solutions, the below Cubis Systems products are certified Made in Britain.