A Range of Cable Protection Solutions used Across Northern Ireland’s Railway Renewals Project

Case Study Details

Client

Northern Irish Railways

Location

Lurgan, Northern Ireland

Product

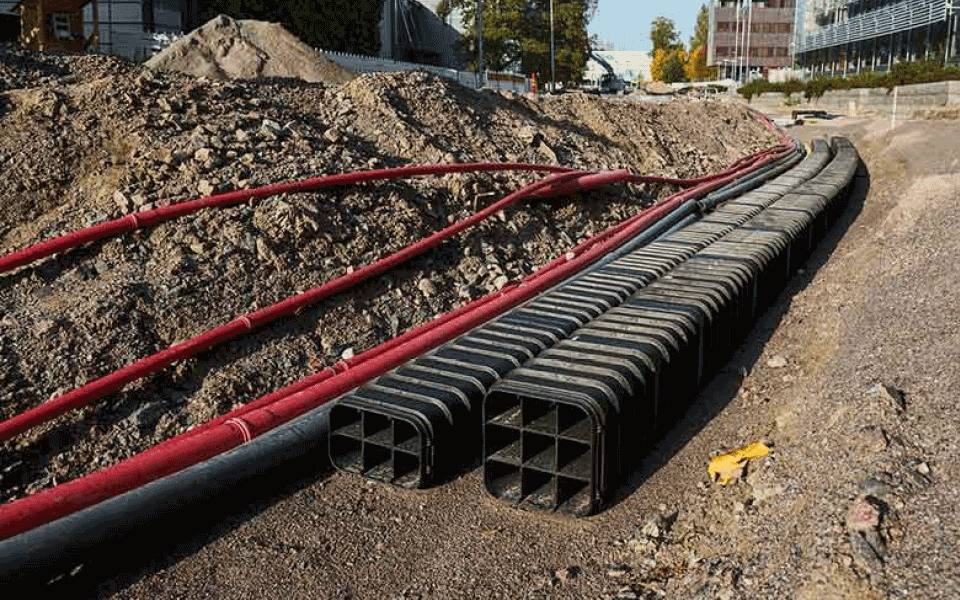

MULTIduct™, PROtrough, STAKKAbox™ ULTIMA Connect, AX-S™ Concrete Infill Cover

Sector

Rail and Light Rail

Case Study

Although operating worldwide, the current railway renewals taking place across Northern Ireland have afforded Cubis the opportunity to work on several local projects, one of which is located less than two miles from their Head Offices and manufacturing site in Lurgan, Northern Ireland.

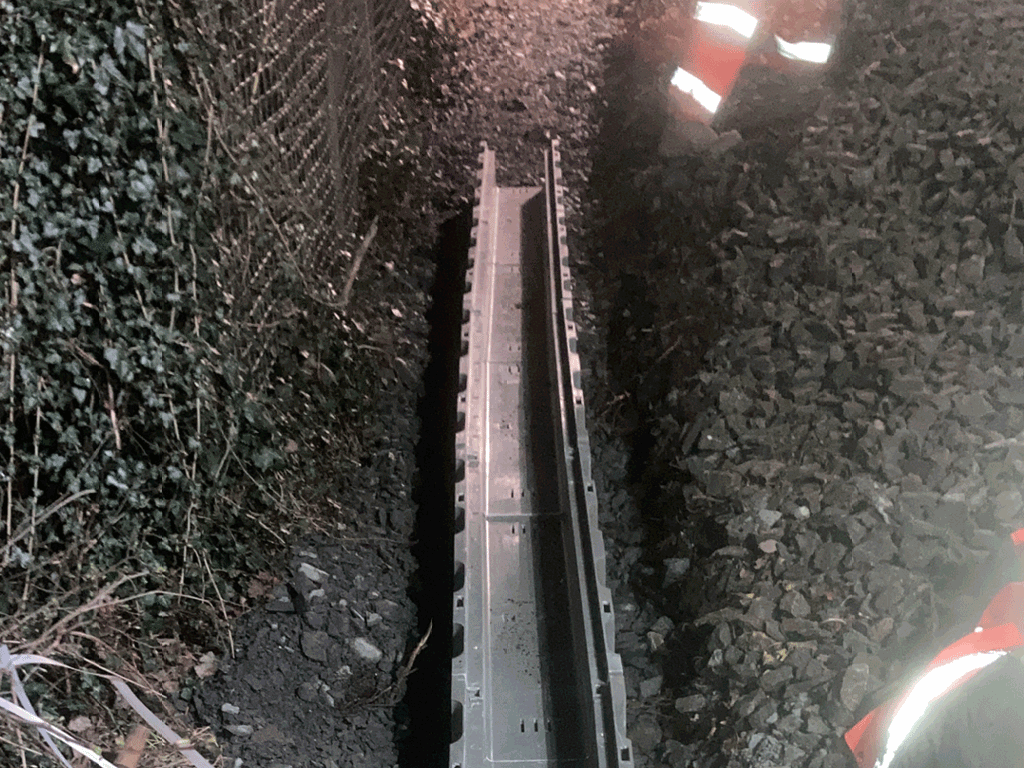

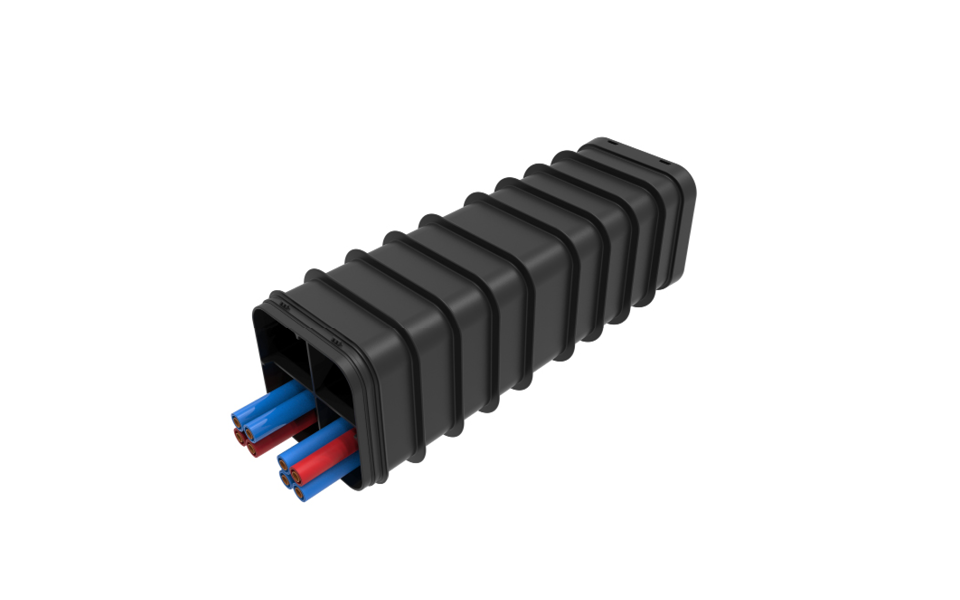

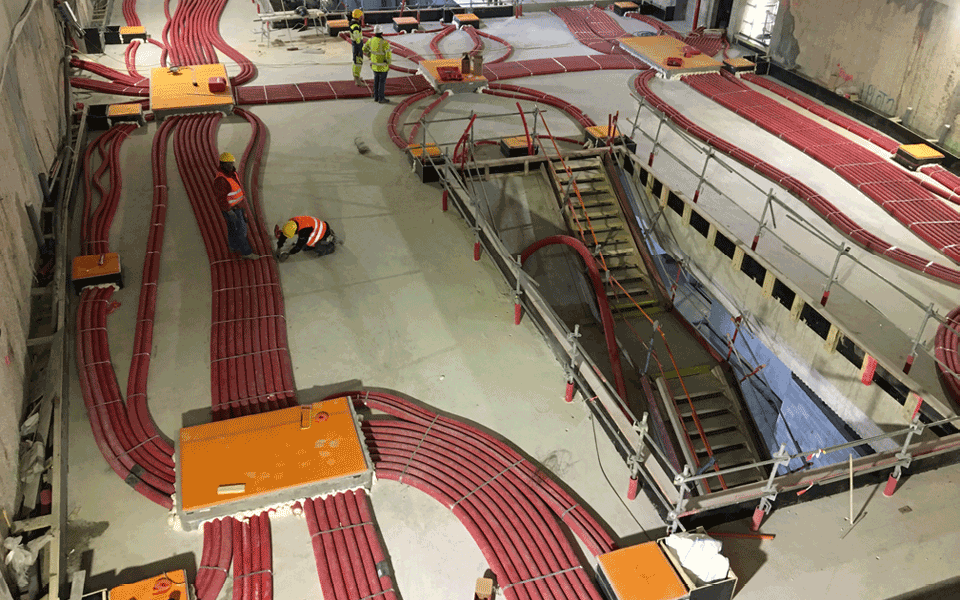

The railway renewals in Lurgan had projected a construction period of eight months, between 4th January 2022 and 1st August 2022. One of the lead engineers involved with the Lurgan project commented, “…what sets Cubis’ products apart is how easy they are to work with. Based on a T3 possession (when working hours are between 00:30- 04:45) on average we were able to install over 66 units of Cubis’ 6-way MULTIduct™ and at least one chamber per shift.” For projects with time constraints, Cubis’ products provide the best solution due to being lightweight, fast to install and easy to transport.

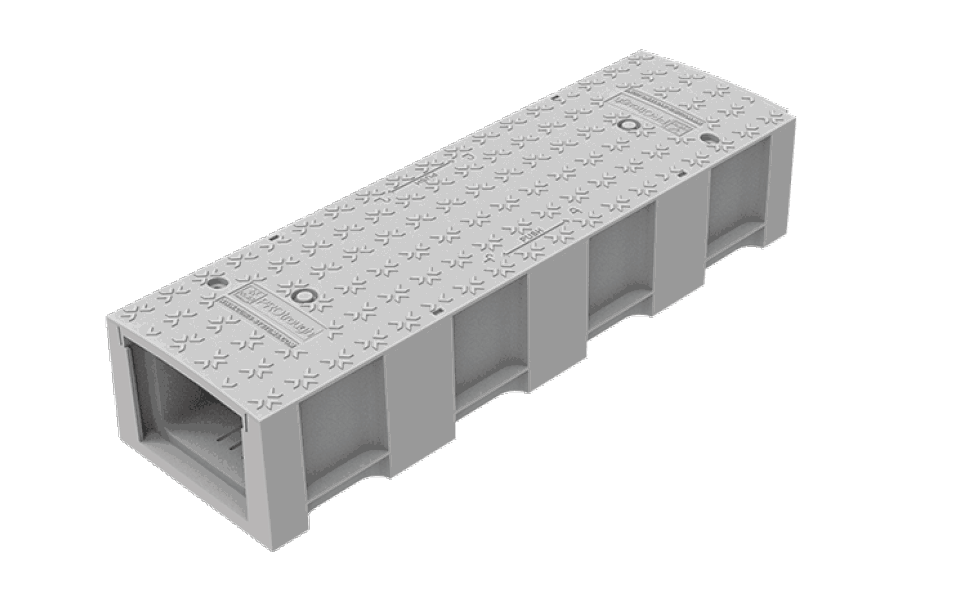

In a recent study conducted by Network Rail, the transportation of concrete cable troughing was compared to that of a polymer trough alternative. Results from the study of concrete cable troughing show that the transportation of 10,000 complete units (lids and bases) required 110 lorries to move the product from Manufacturer to Site. In comparison, under the same circumstances, the lightweight version only required 20 lorries, resulting that PROtrough reduces the required transportation by more than 80%. Like many other Cubis products, PROtrough is also 100% reusable, further helping to reduce the environmental impact of your infrastructure project.

Cubis’ products are intelligently designed with the user in mind. As well as reduced transport costs and environmental impact, PROtrough also helps to reduce the risk of injury to your workers. During the installation process of polymer cable troughing, each worker is required to support only 6kg, in contrast to concrete cable troughing which requires each worker to support 27kg. PROtrough can be easily unloaded manually and requires no heavy plant on site, it is also stackable and can be easily stored.

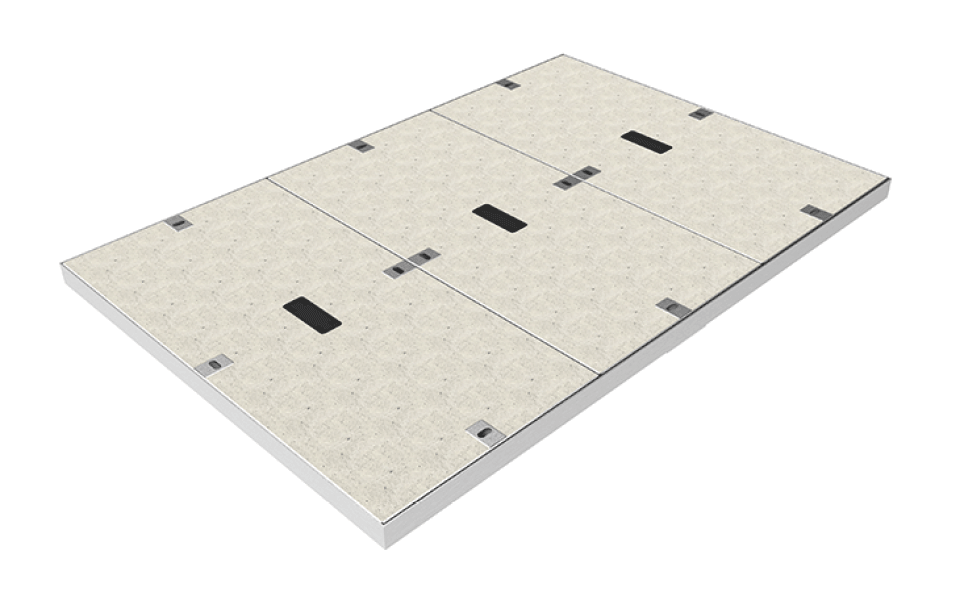

The project that is currently underway in Lurgan will deliver vital renewals and upgrades of nearly 9km of existing signalling and telecoms infrastructure, including the construction of retaining walls in several locations, a new continuous duct route and full lineside cable renewals. Cubis has continuously supported the project through the supply of their innovative network access chamber system STAKKAbox™ ULTIMA, their cable protection system MULTIduct™, and their lightweight troughing system PROtrough.

When the Lurgan Line Railway Renewals are complete, NI Railways will benefit from an improved overall performance of the rail network, reduced levels of maintenance needed in the long term, and their high safety standards upheld. Perhaps you are currently involved with a project that has the same end goals? We would love to connect with you and help you achieve success with your specific infrastructure projects.

To follow updates on Northern Ireland’s Railway Renewals, visit our website and follow us on LinkedIn. If you are interested to learn more about how Cubis’ products can benefit you, please contact a member of the team, or alternatively contact Danielle Devlin; Area Manager for Ireland.