Telecoms Access Chamber Replacement Project

Case Study Details

Client

Rogers TV

Location

Ottawa, Canada

Product

STAKKAbox™ ULTIMA Connect

Sector

Telecoms

Case Study

The Cubis STAKKAbox™ ULTIMA proved to be a natural fit for a telecommunications infrastructure replacement, owing to its ease of installation, flexibility to site conditions, and the ability to install the chamber without outages to in-place fiber cable.

Project Challenges

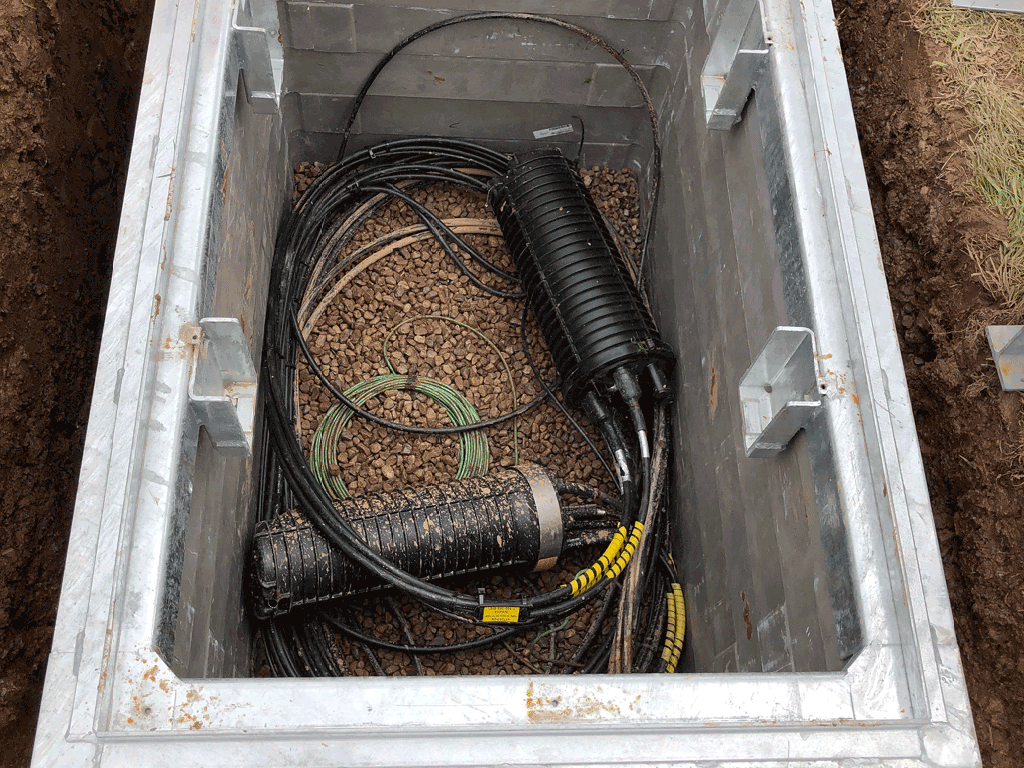

Telecommunications providers use draw pits to splice fiber optic cables and store additional cable slack. Over time, pull boxes deteriorate and need replacing both to protect components and to allow more room for cable storage and additional fiber lines to meet ever increasing demand.

In this replacement project for Rogers TV in Ottawa, Canada, existing fiber optic lines and ducting were running through three sides of a splice box. Typically, to replace such a box without a break in service, a large “mouse-hole” must be cut into the new box on any side where it is being placed over existing cable. Adding these large holes usually compromises the integrity of the access chamber and causes it to fail prematurely.

In addition, such projects frequently come with a degree of uncertainty, since it is often not known exactly how deep the replacement box will need to be—creating the need for guesswork.

Cubis Solution

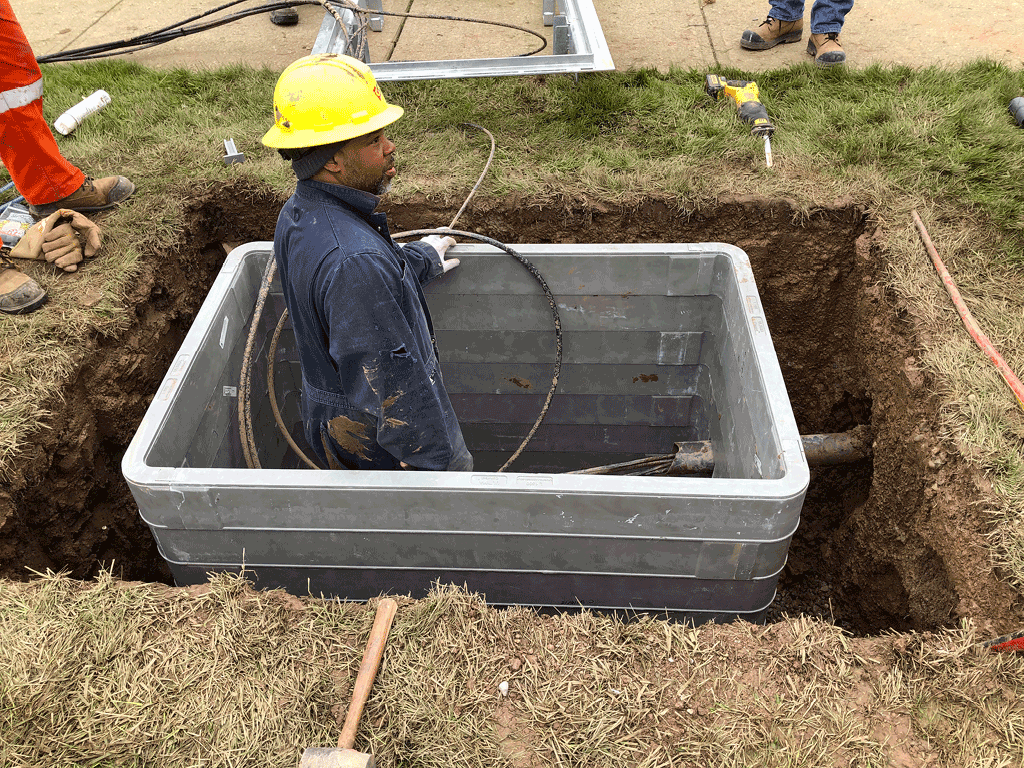

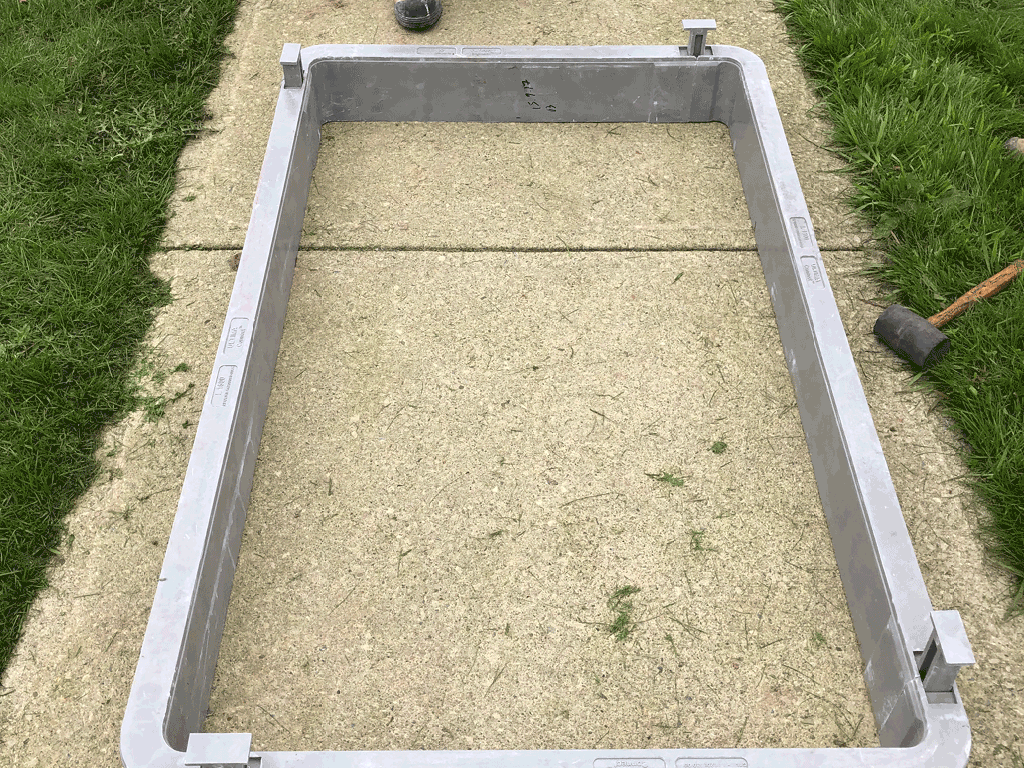

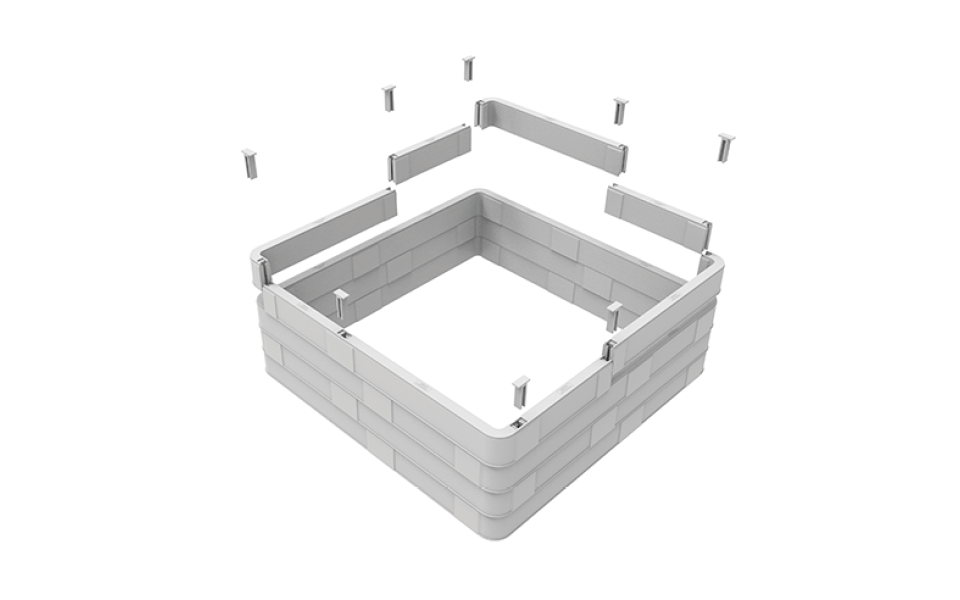

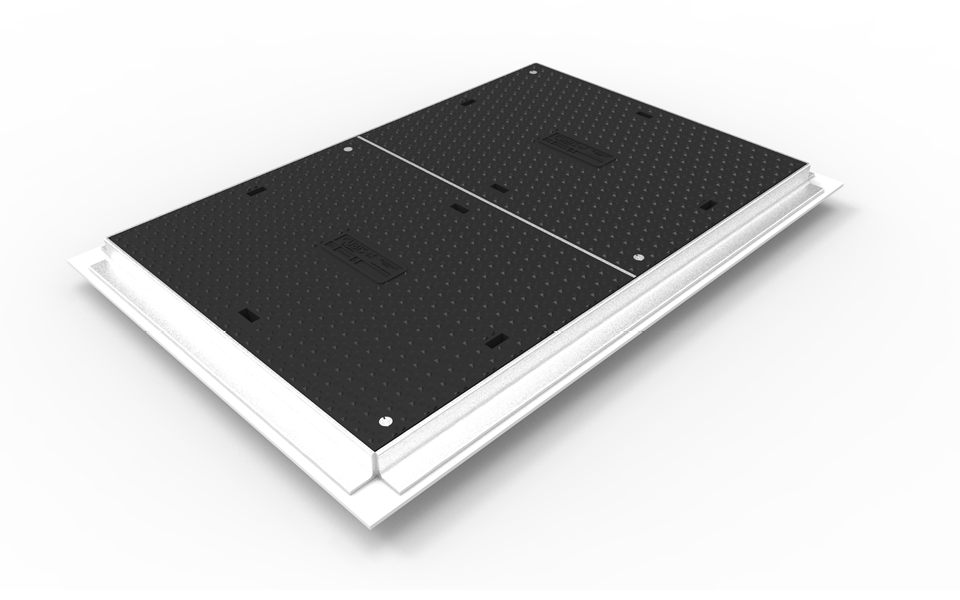

For this effort, Oldcastle Infrastructure provided one 915mm x 1500mm x 1370mm STAKKAbox™ ULTIMA unit with AX-S™ Composite Covers. The unit was delivered flat-packed (unassembled) and then constructed on site.

Installation was extremely straightforward:

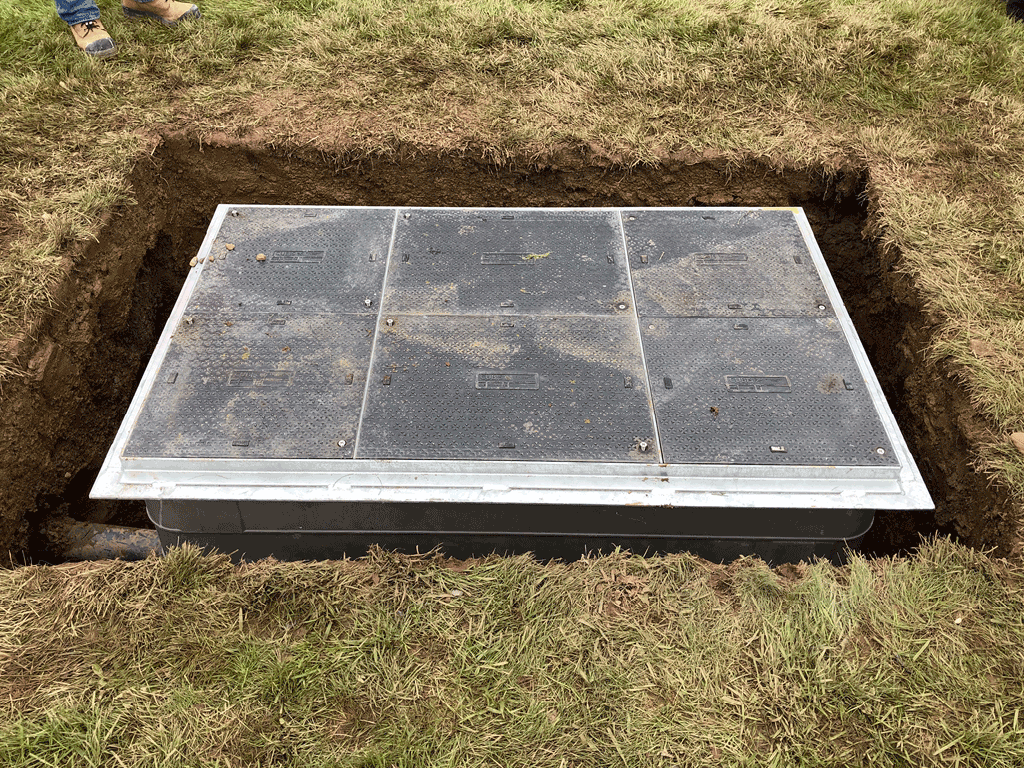

- An excavator was used to dig the hole and remove the existing access chamber.

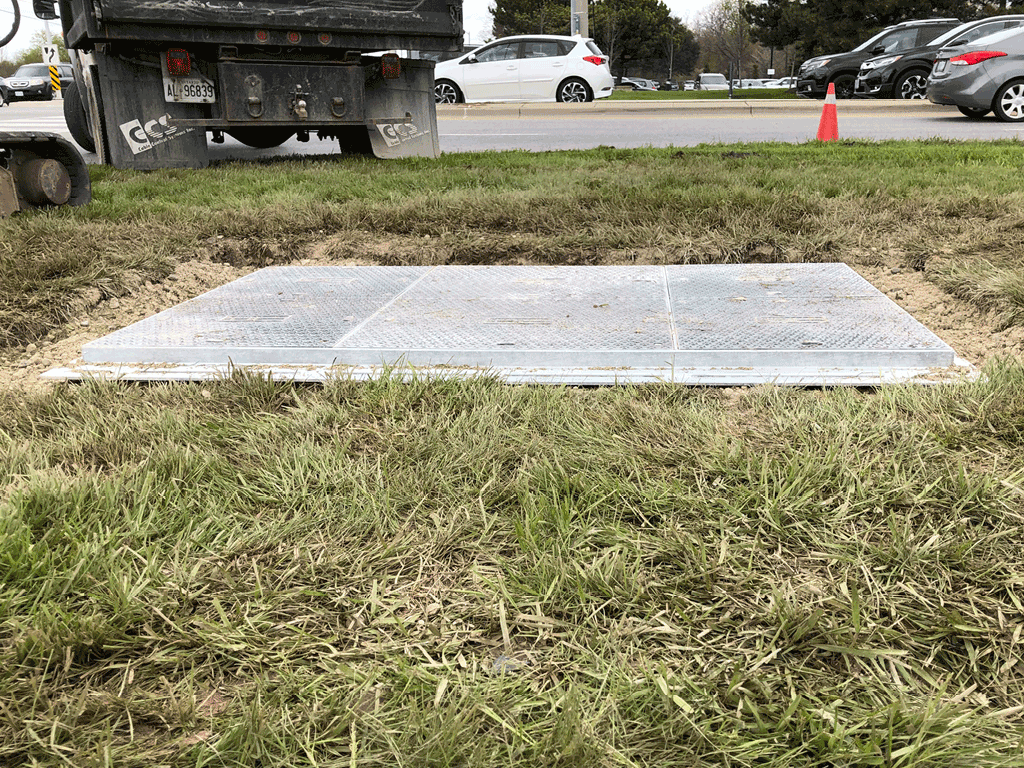

- The ground was leveled for placement of the new chamber assembly.

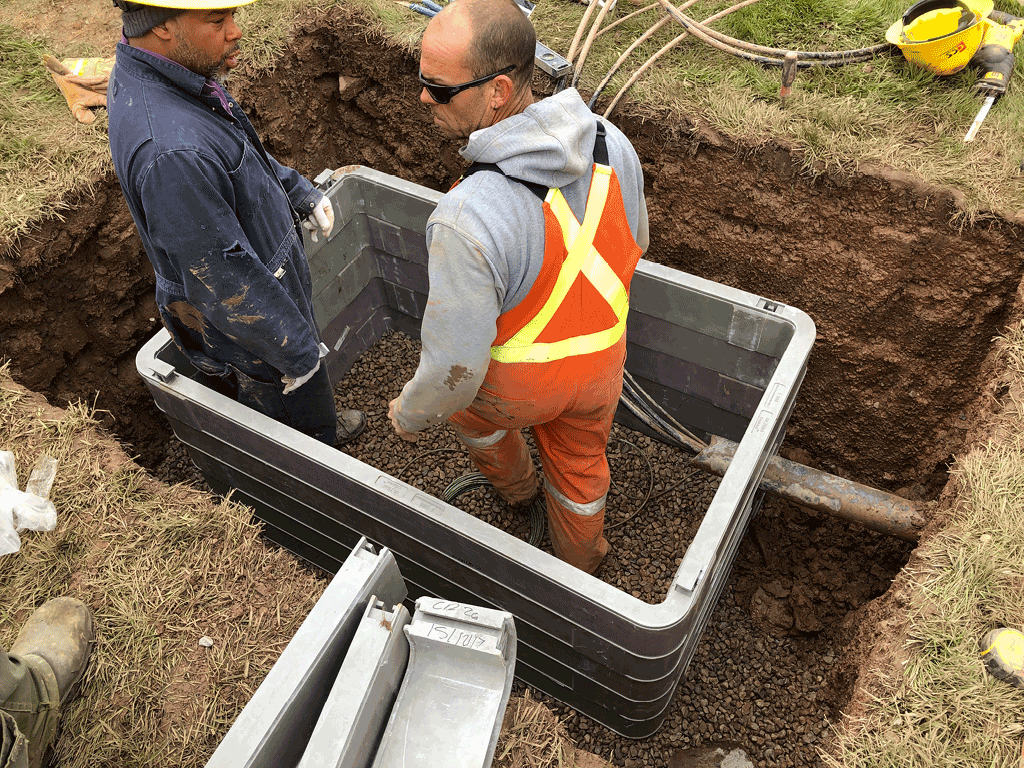

- The ULTIMA chamber was built from the ground up, using components and connecting pegs, one layer at a time.

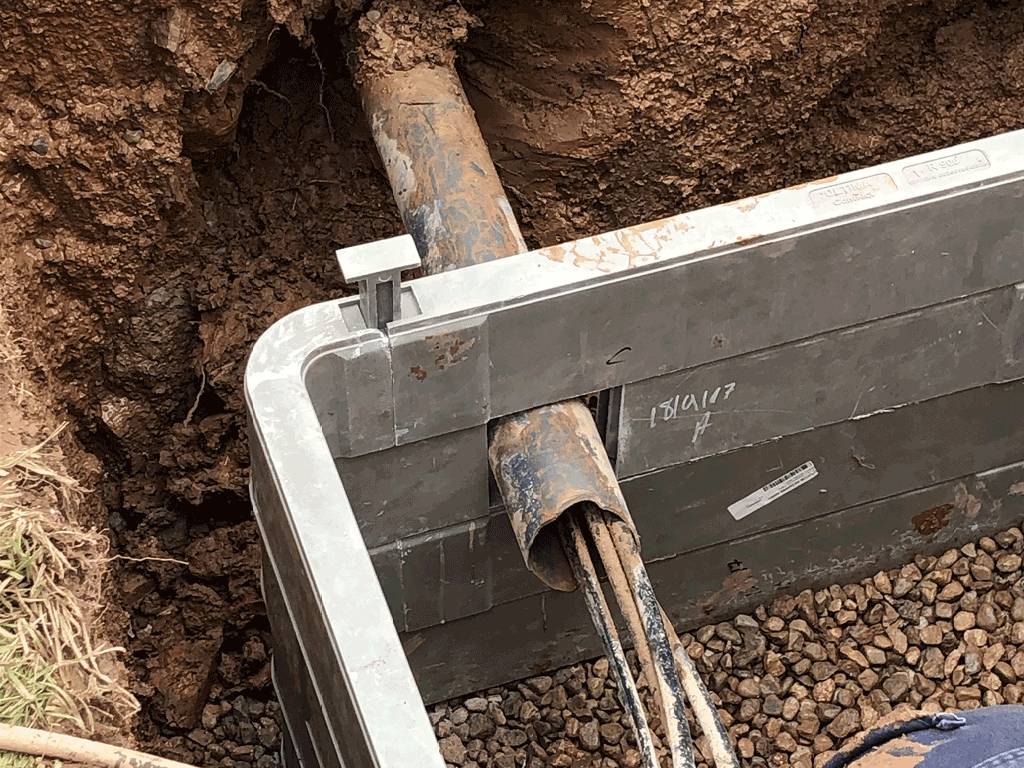

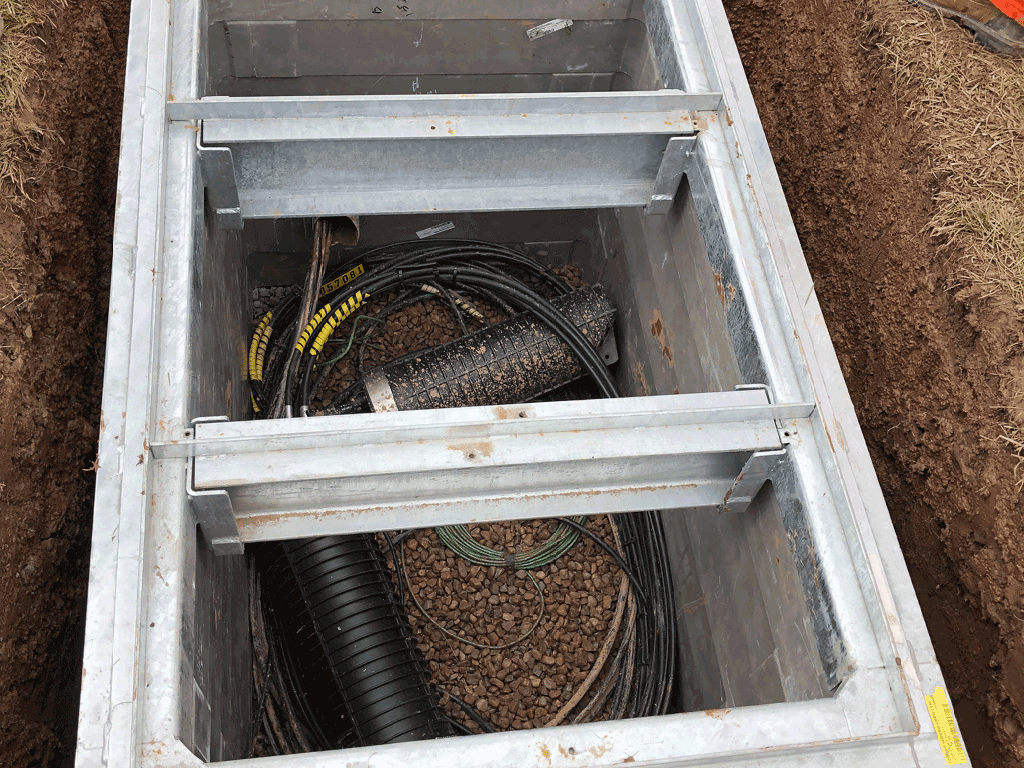

- As the rising walls of the chamber approached ducting or fiber optic lines, the chamber components were easily cut with a saw to allow for building around the obstructions.

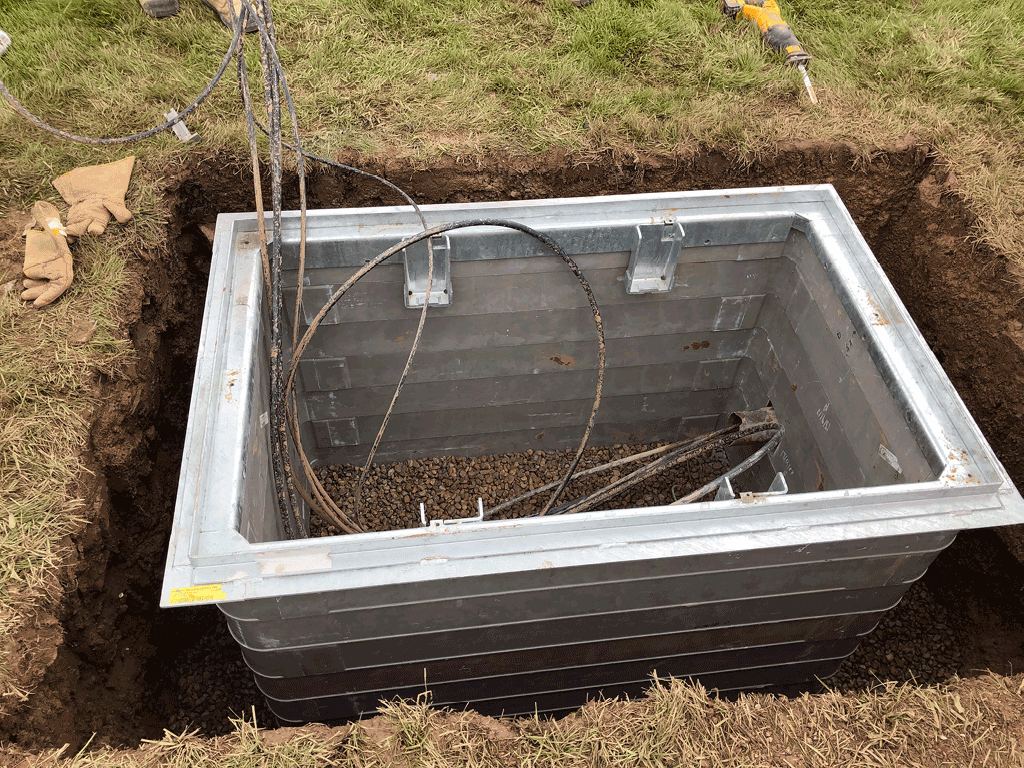

- The layers were built to the required final grade.

- The frame was placed and screws were used to secure the composite covers to it.

The total time for installation was approximately 4 hours (one half-day).

We foresee substantial time and cost savings when replacing or upgrading pull/splice boxes—quickly and with

minimal impact. - Chris Schultz, Product Manager

Customised Depth

The Cubis STAKKAbox™ ULTIMA Connect system gave Rogers TV the flexibility to dig the hole and place the chamber as deep as necessary without concern for the chambers ultimate height. During the building process, the number of layers could be easily adjusted to bring the chambers final height to grade level—a huge advantage over the typical installation.

No Interruption in Service

Because the Cubis STAKKAbox™ is constructed around the existing infrastructure, it minimizes outages when upgrading/replacing a current draw pit.

Workers simply drill or cut holes in the ULTIMA Connect layers where necessary as the box is built. This process allows existing fiber optic cable and ducting to pass through the sides without affecting any lines currently in service.

This feature is especially important in confined urban environments that often have both deteriorating equipment/ infrastructure and high demand due to the population density.

No Impact on Chamber Integrity

The Cubis layered system for integrating existing cable does not impact the integrity of the chamber, unlike the large holes that must be cut in typical replacement boxes. The STAKKAbox™ can be customized to meet the unique site requirements while ensuring a load resistance well above the ANSI/SCTE Tier 22 standard.

Speed & Cost-Effective Installation

The Cubis STAKKAbox™ ULTIMA provides huge advantages in installation time, ease, and labor effort. In as little as four hours, the chamber can be built and installed on site with lightweight components following a straightforward assembly process.

The Rogers TV crew was extremely impressed with the innovation of the STAKKAbox™. They foresee substantial time and cost savings when replacing or upgrading pull/splice boxes—quickly and with minimal impact.