Queensland Rail: Corinda and Roma Street Station Signal Upgrade

Case Study Details

Client

Queensland Rail

Location

Queensland, Australia

Product

STAKKAbox™ ULTIMA Connect, Concrete Cover Slab

Sector

Rail

Case Study

As part of the Queensland Rail (QR) Signal Upgrade Project taking place between Corinda and Roma Street Station, Cubis Systems were approached to provide an innovative chamber solution, ensuring reliable long-term protection of underground electrical and communication services.

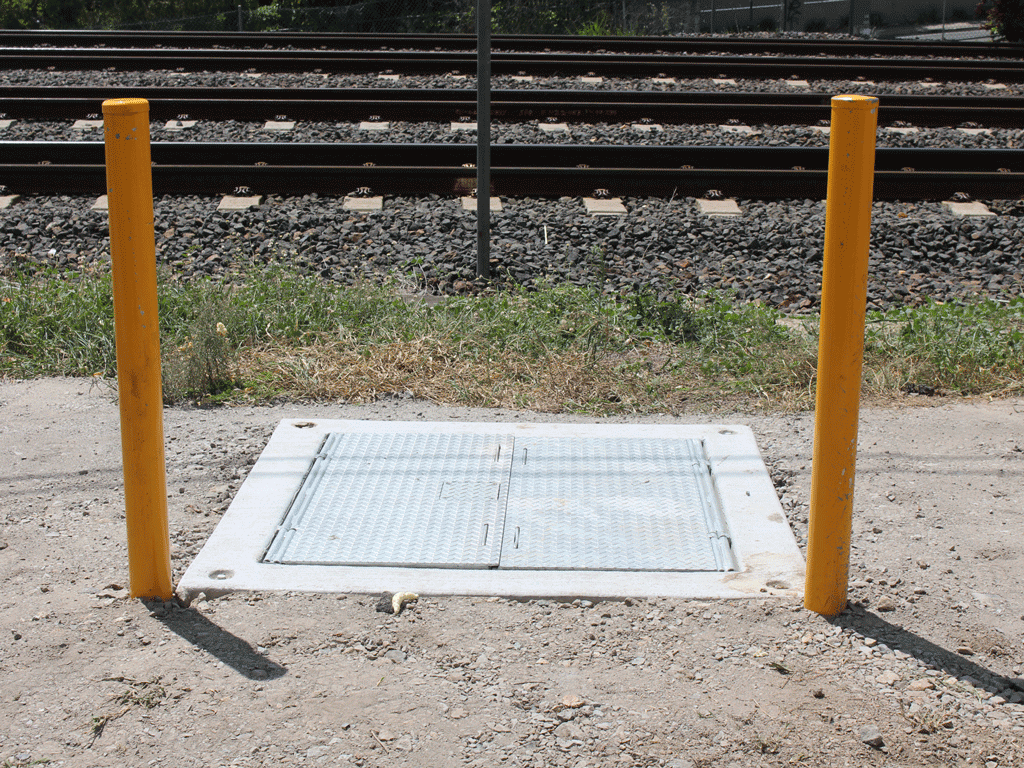

Located at the Indooroopilly site in Queensland, Australia, the upgrade took place within 4 meters of the live rail network. Challenges presented by the QR project were quickly overcome utilising the versatility of STAKKAbox™ ULTIMA Connect.

Project Challenges

- Close proximity to a live rail network

- Existing live services to be incorporated within the new chamber

- Time restricted site access

- Remote location with no power on site

Of particular significance was the elimination of any WHS risks, a fast, cost-effective installation and minimal use of heavy-lifting machinery.

Traditional chamber options could not successfully meet all QR project objectives. A pre cast concrete chamber would require extensive, costly, and time consuming chamber modifications to be performed on site, while pouring an in-situ chamber would also take a considerable amount time, requiring additional machinery and specialist builders. Both options would therefore lead to overall increased installation costs.

Cubis Systems Solution

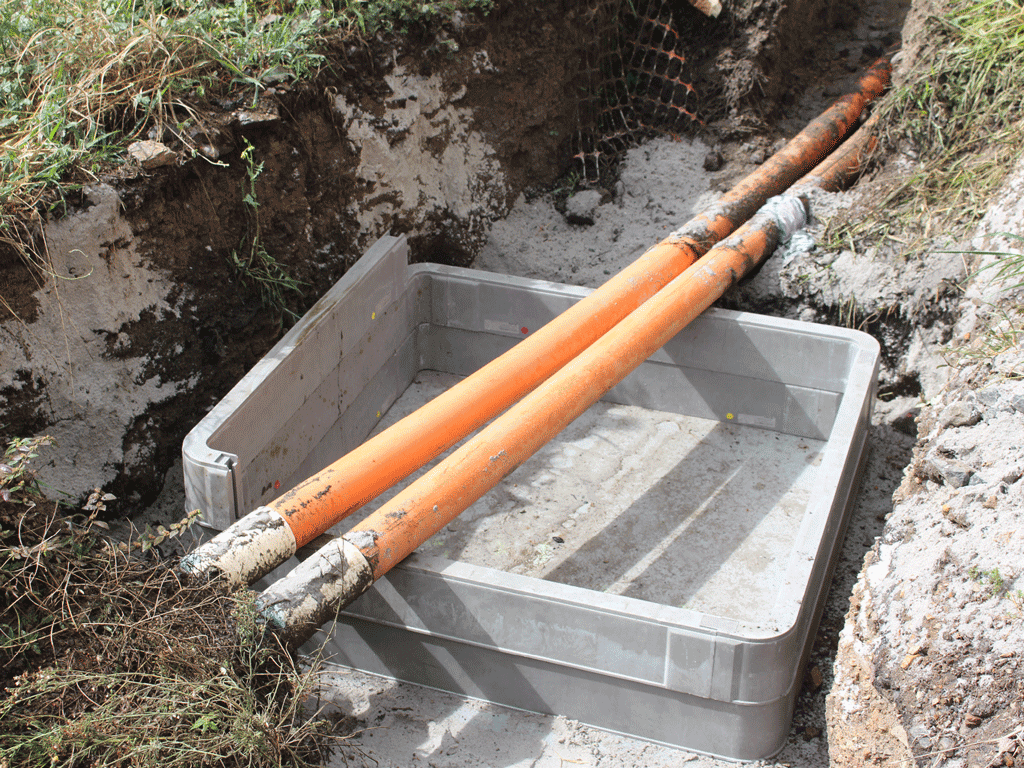

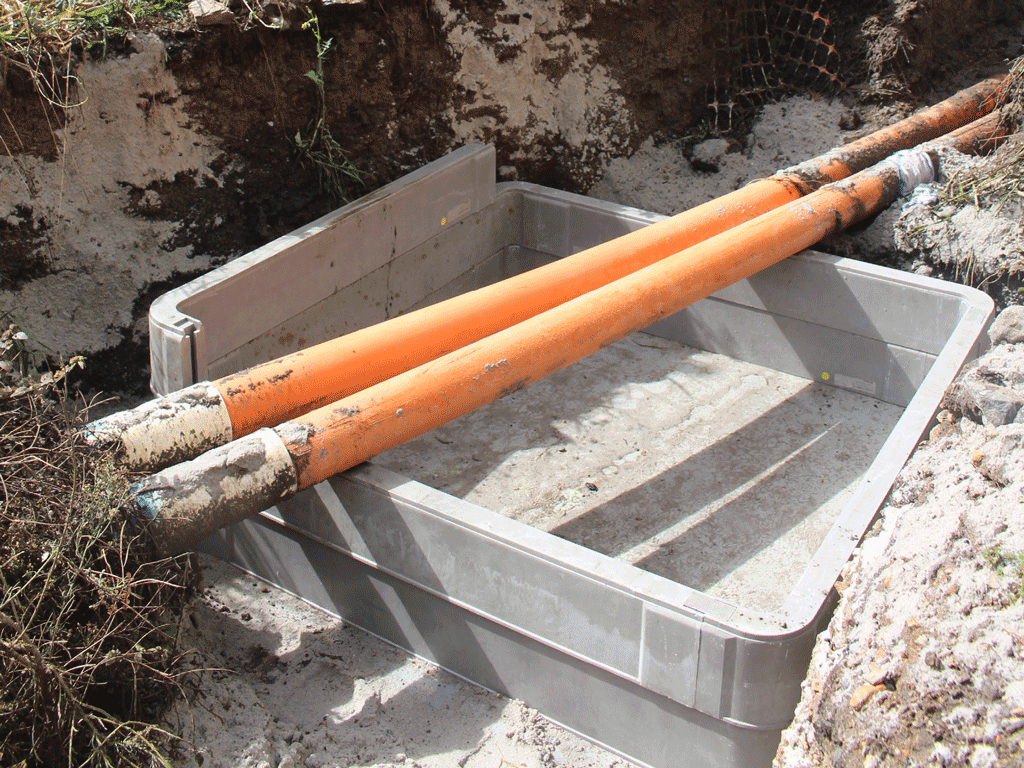

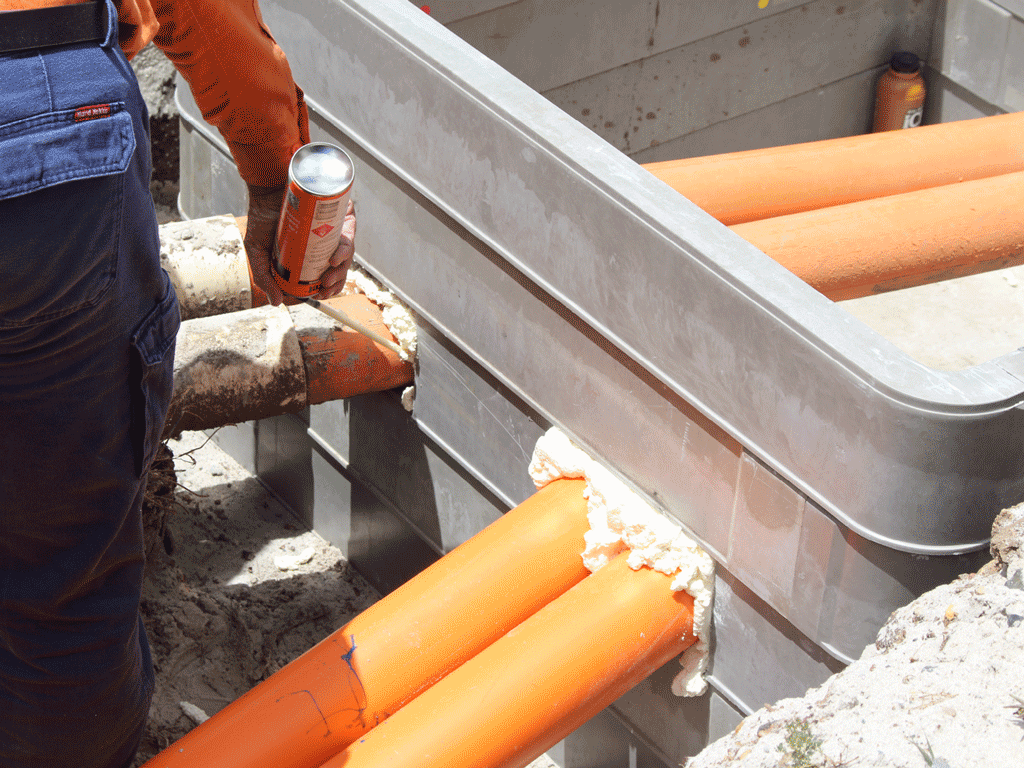

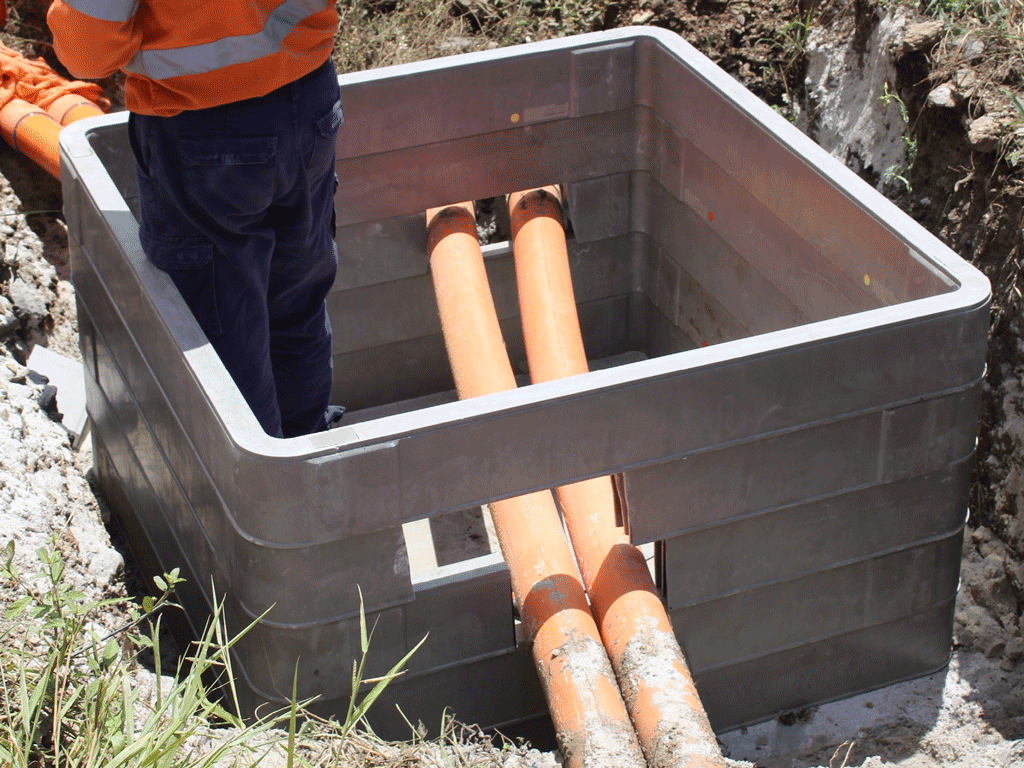

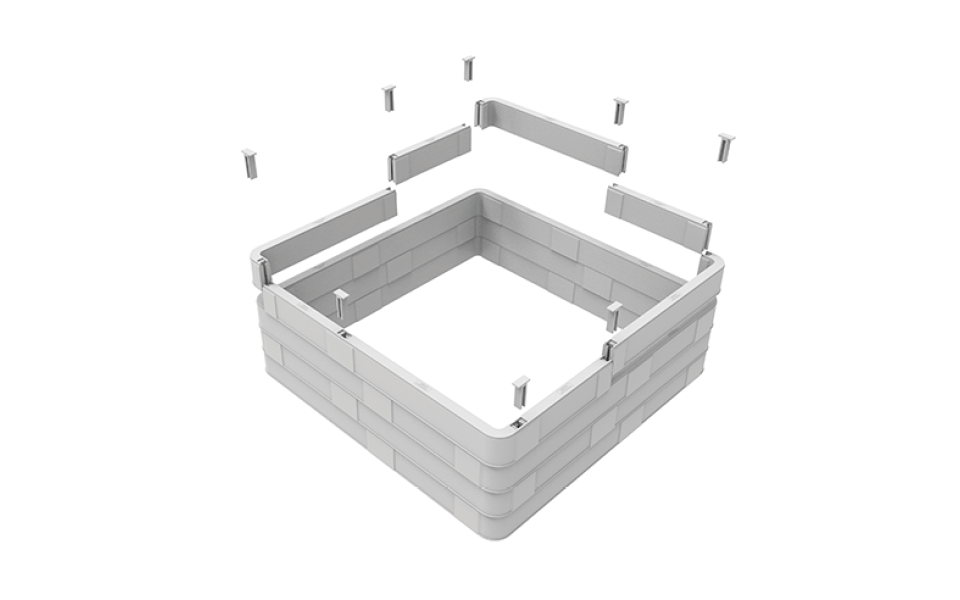

The modular structure of the STAKKAbox™ ULTIMA Connect allowed for easy onsite installation around two (2) existing live 100mm conduits and the inclusion of seven (7) new additional 100mm Conduit ducts running directly through the chamber, connecting to the existing network system. A pre cast concrete floor was installed as a base for the ULTIMA Connect chamber which reduced build time and increased efficiency, avoiding the need to cast a base floor on site.

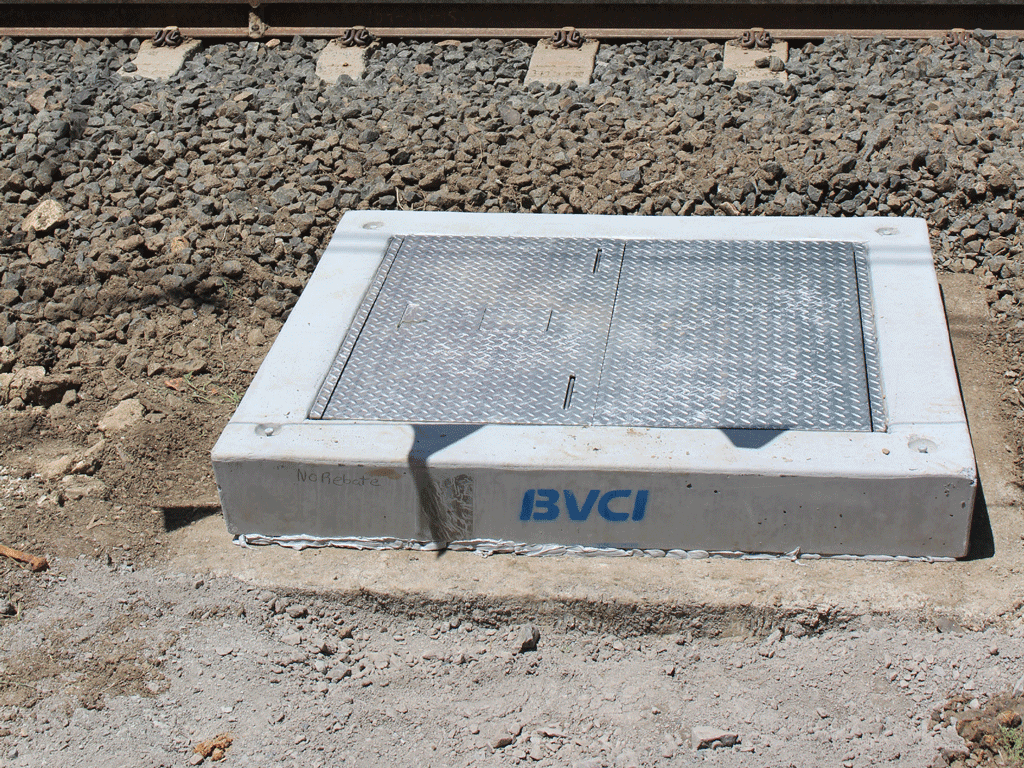

QR also completed upgrades to a secondary existing cast in-situ chamber, which required the installation of a QR approved standard access cover, while also increasing the finished surface level by 200mm to meet changing site conditions. A custom preformed roof encasement and access cover were also provided by Cubis.

Project Outcomes

Successful installation around the existing and new infrastructure networks were carried out in a safe, cost-effective, and timely manner due to the modular structure of the STAKKAbox™ ULTIMA Connect. Modifications to the chamber were conducted using both standard battery powered and hand tools. The ULTIMA’s lightweight properties enabled efficient transportation and assembly on site, with no skilled builders or heavy machinery required to quickly construct the STAKKAbox™ chamber.

STAKKAbox™ ULTIMA Connect’s high strength properties ensured Queensland Rail’s standard load classification was achieved, eliminating the need for additional deliveries and increased costs associated with concrete or specialised backfill materials.