10 things you didn’t know about the trade moulding service from Cubis Systems

At Cubis Systems, we’re known for manufacturing infrastructure solutions here in the UK. What many don’t realise is that we also offer a full trade moulding service.

You could be:

- Developing a new component

- Looking for rapid prototyping

- In need of large-scale manufacturing with tight tolerances

Either way, our end-to-end trade moulding service has you covered. Here are 10 things you probably didn’t know we could do for you.

1. We help you shape the idea

Our support starts with collaborative ideation. We can engage with your team early-on for an initial kick-off. So, for example, we can help with defining the concept, exploring use cases, selecting materials, and evaluating feasibility.

Importantly, this all happens before any tooling begins – helping shape a commercially viable product from day one.

2. We manage the whole project, not just the moulding

We assign a dedicated team and run every project through our New Product Introduction (NPI) and Advanced Project Management (APM) frameworks. That means clear timelines, traceable progress, and one point of contact from concept to completion.

3. We stress-test your design before it’s made

We use Finite Element Analysis (FEA) and mould flow simulations to assess your design’s performance and manufacturability. For you, this means no costly surprises. Our analysis and simulations accurately predict how materials will behave under real-world pressures.

4. We deliver working prototypes fast

Need to test fit, function, or form before full production? Our rapid prototyping service gets you physical samples quickly. So, it’s ideal for stakeholder approvals, on-site fit trials, or design tweaks.

5. We have trusted toolmakers in the UK & Asia

Once you're ready for custom tooling, we manage the process through our long-standing partners – with a strong toolmaker network both here in the UK and in Asia. You’ll also receive pre-production samples for sign-off before the final tooling goes live. At every stage, communication and quality assurance are paramount.

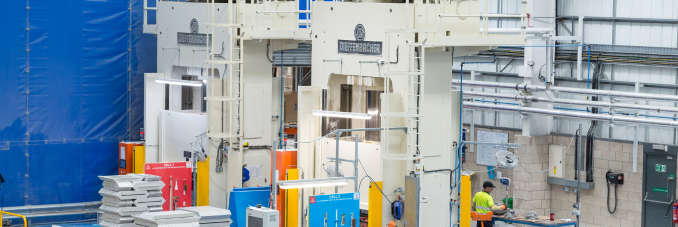

6. We offer multiple moulding technologies

Our UK facilities include:

- 8 injection moulding machines (130t–1350t)

- 1 gas-assisted low-pressure machine (up to 76kg shots)

- 27 compression moulding presses (150t–1200t)

From precision parts to large enclosures, we’ve got the machinery and flexibility to handle your needs.

7. We’re a multi-material manufacturer

We work with multiple materials across our trade moulding facilities, including:

- LDPE, Nylon 6, Acetal

- Fire-resistant SMC and BMC composites

- Recycled polymers where required

We even produce BMC in-house, giving us control over formulation and performance.

8. We build custom jigs & fixtures for assembly

If your part needs secondary assembly, we’ve got it covered. We design and manufacture bespoke jigs and fixtures to ensure efficient, repeatable builds. And, if required, we’ll deliver you fully assembled units.

9. We’re ISO Certified for Quality and Environmental Management

Every product we manufacture follows a strict quality control process, backed by ISO certifications:

- BSI 9001 – Quality Management

- BSI 14001 – Environmental Management

You can trust us to meet the highest standards, batch after batch.

10. We’re an end-to-end manufacturing partner

Working with Cubis Systems means you get more than just parts. You get a strategic partner who understands manufacturing complexity, who de-risks development, and who supports your growth. All with British-based production and global reach.