STAKKAbox™ ULTIMA Connect:

The smarter alternative to concrete access chambers

When it comes to underground utility access chambers, traditional concrete solutions have long been the industry standard.

However, reliance on concrete access solutions comes with significant challenges.

For contractors, common pain points include heavy manual handling, long installation times, and limited flexibility. Meanwhile, for asset owners and designers charged with overseeing the sustainability of infrastructure projects, the inherently high carbon footprint of concrete only compounds these practical issues.

Enter STAKKAbox™ ULTIMA Connect – the smarter alternative to concrete access chambers. Here’s a look at how our innovative, modular, and sustainable solution is transforming the way infrastructure projects are completed.

The problem: traditional concrete chambers come with significant drawbacks

In the time it takes you to read this sentence, the global building industry will have poured more than 19,000 bathtubs of concrete.

Unfortunately, defaulting to concrete solutions can lead to major environmental, physical, and operational detriments.

To look specifically at underground concrete access chambers, just some issues include:

-

Slow installation

Concrete chambers take 1-2 days to install, delaying projects and increasing labour costs

-

Heavy manual handling

A single 150mm deep section weighs around 44kg, requiring multiple workers or heavy lifting equipment

-

Limited size flexibility

Pre-cast concrete chambers come in fixed sizes, restricting customisation

-

Structural wear and tear

Over time, concrete is prone to cracking and chemical degradation, leading to costly repairs and replacements

-

High environmental impact

Concrete production is energy-intensive and has a large carbon footprint

For asset owners, contractors, and engineers alike, these issues contribute to multiple headaches. Their projects cost more, take longer to complete, involve more risk, and can miss key environmental goals.

Fortunately, as innovation sweeps through the construction industry, there is no longer the need nor the justification to default to concrete for every project.

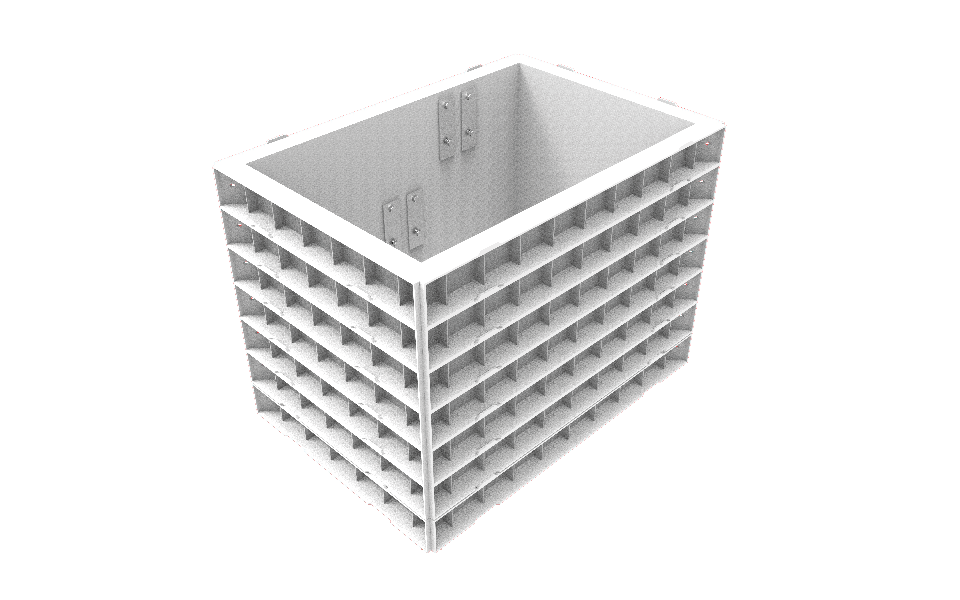

The solution: STAKKAbox™ ULTIMA Connect

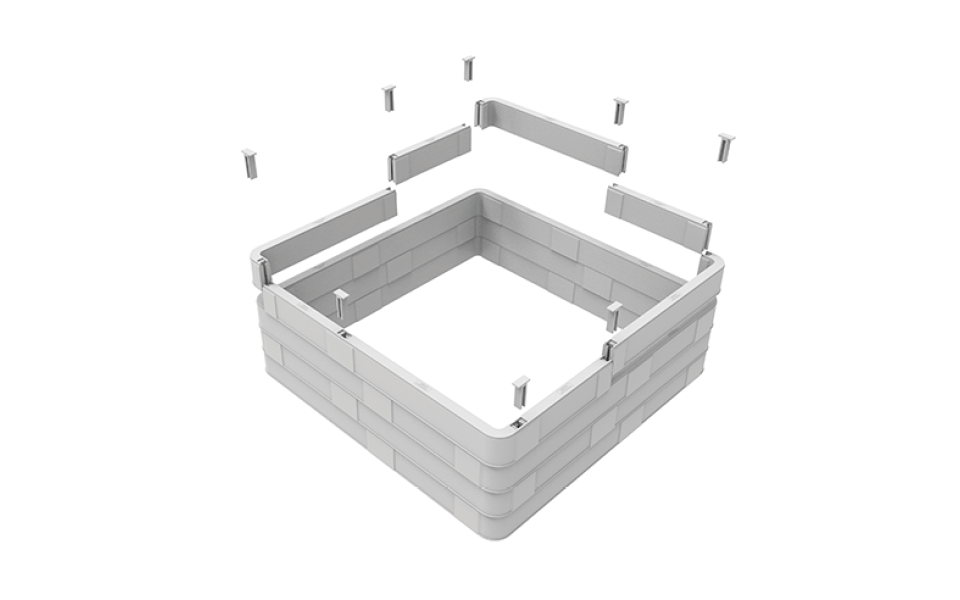

STAKKAbox™ ULTIMA Connect is a modular, high-performance alternative to concrete chambers. Not only does the solution eliminate all of the above issues, it delivers a more efficient, cost-effective, and sustainable network access solution. Here’s how:

1. Faster, simpler installation

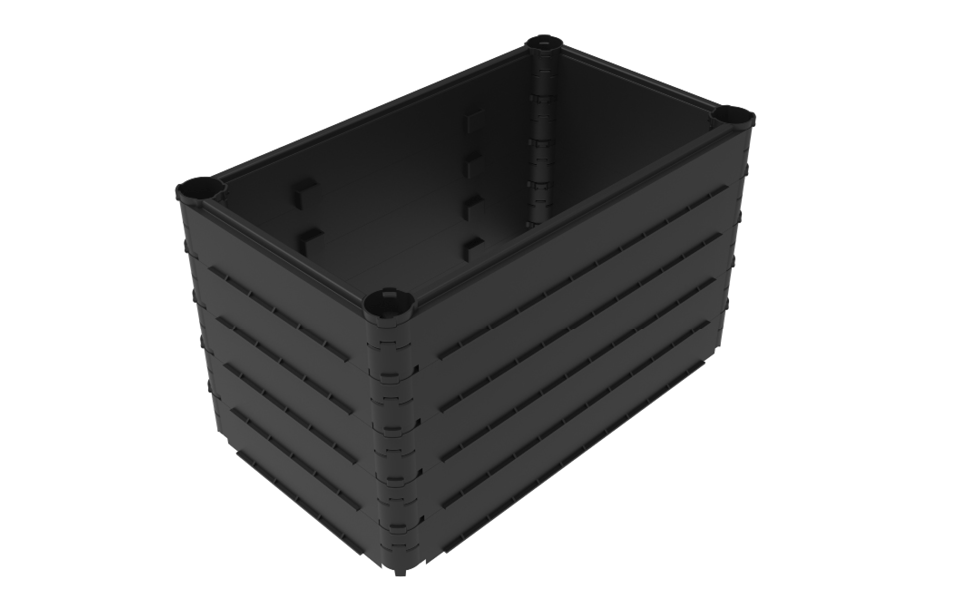

ULTIMA Connect can be fully installed in just one hour – a fraction of the time required for traditional concrete chambers. The modular design allows for rapid assembly, minimising site disruption and reducing labour costs.

2. Lightweight and easy to handle

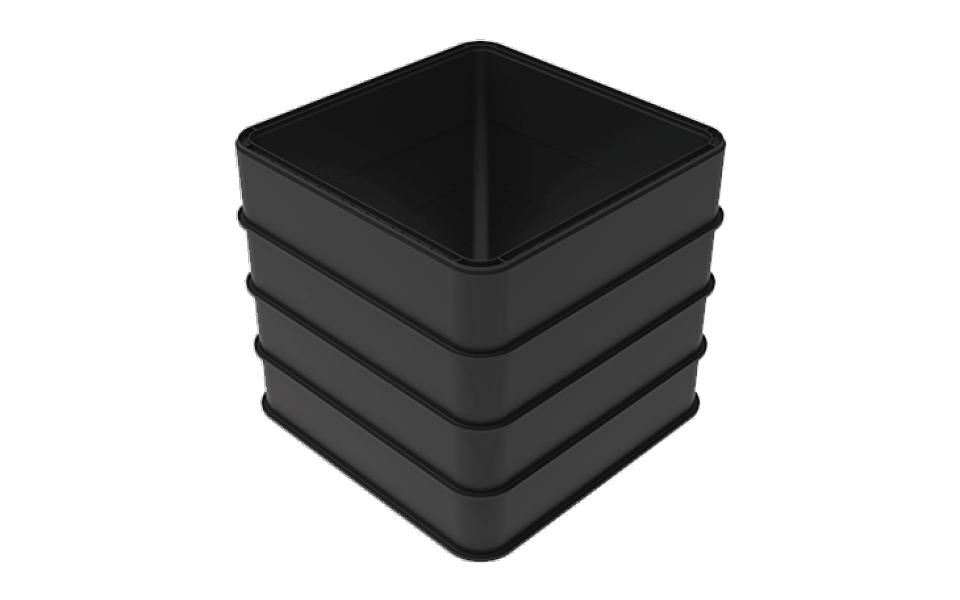

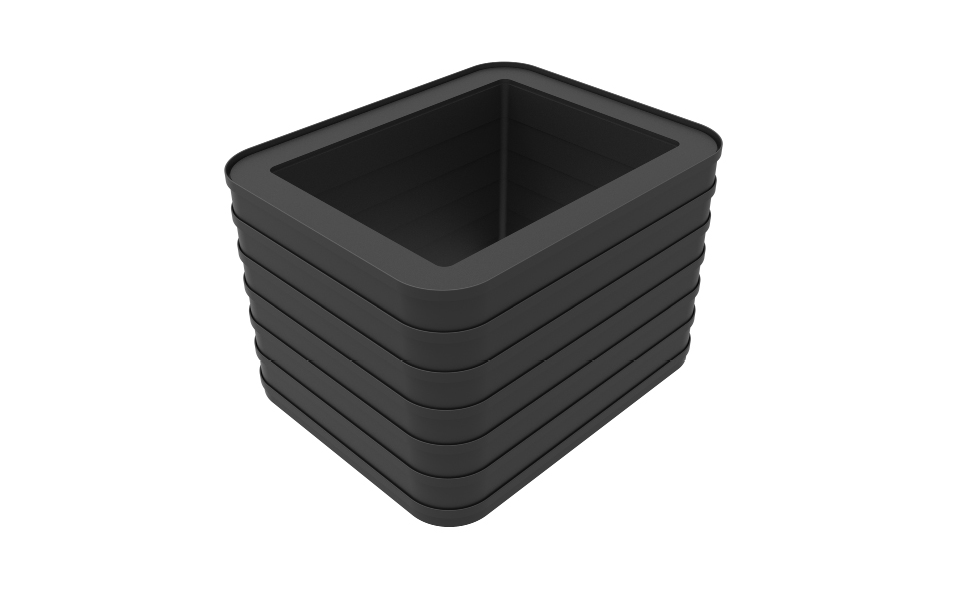

Each 150mm deep section weighs less than 10kg, making it a safe single-person lift. This reduces manual handling risks, eliminates the need for specialist lifting equipment, and simplifies transportation.

3. No limits on size – fully scalable design

Unlike fixed-size concrete chambers, ULTIMA Connect can be built to any required size. The system’s modular components provide complete flexibility, making it easy to create custom-sized chambers that meet specific project needs.

4. Strength without the weight

Despite being lightweight, ULTIMA Connect delivers exceptional strength and durability.

- Meets and exceeds F900 load ratings under EN124, making it suitable for high-load environments such as docks and airfields

- Interlocking twin-wall design enhances sidewall strength, outperforming conventional concrete chambers

5. Enhanced chemical resistance for long-term performance

Traditional concrete is highly susceptible to chemical attack, leading to structural degradation. ULTIMA Connect’s Glass-Reinforced Plastic (GRP) construction is highly resistant to chemical exposure, extending the product’s lifespan and reducing maintenance costs.

6. A more sustainable choice

Concrete is one of the largest contributors to global CO₂ emissions due to its energy-intensive production. ULTIMA Connect is a more sustainable alternative:

- GRP production has a significantly lower carbon footprint than concrete manufacturing

- Flat-pack delivery reduces transport emissions by optimising space and reducing the number of shipments required

- Longer lifespan means fewer replacements, leading to less waste and lower long-term environmental impact

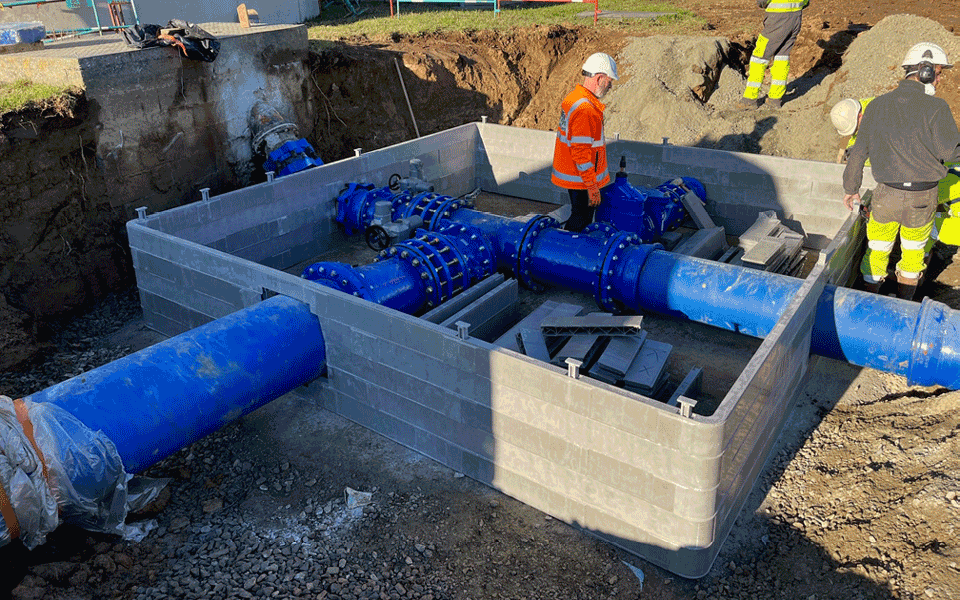

Real-world success stories

These benefits aren’t simply speculative.

Major projects across the UK have already benefited from the advantages of ULTIMA Connect. In locations such as Canary Wharf and the Queen Elizabeth Olympic Park, contractors have leveraged the system’s speed, flexibility, and strength to complete installations faster and more efficiently than ever before.

As dozens of Cubis case studies show, modular, lightweight access chambers are rapidly making a difference to how our world is built.

A smarter investment for future infrastructure

By switching to STAKKAbox™ ULTIMA Connect, asset owners and contractors can solve the persistent challenges of traditional concrete access chambers. The benefits are clear:

- ~75% faster installation time

- ~80% reduction in manual handling risks

- Fully scalable to meet any project requirement

- Unrivalled strength and chemical resistance

- A more sustainable, eco-friendly choice

If you’re looking for a more efficient, cost-effective, and sustainable alternative to traditional concrete chambers, STAKKAbox™ ULTIMA Connect is the solution you need. Contact the Cubis team today to learn how ULTIMA Connect can improve your next project.