Is GRP a more sustainable concrete alternative?

Concrete vs. plastic-based access chambers

As sustainability becomes an essential pillar of infrastructure planning, the materials we choose for underground systems are under greater scrutiny than ever. At Cubis Systems, one question regularly comes our way:

“How are your plastic-based products any more sustainable than the concrete alternative?”

It’s a fair challenge, and one we’re glad to tackle.

Concrete and the carbon problem

Traditionally, bricks and concrete had long been the default for access chambers. The materials are strong, widely available, and well understood. But concrete construction comes with a hidden cost.

- Concrete production is responsible for around 8% of global CO₂ emissions

- If the cement industry were a country, it would be the third largest carbon dioxide emitter in the world

- Concrete uses up almost a 10th of the world’s industrial water

- Source

Without diving into excess detail, concrete is one of the most carbon-intensive building materials on the planet.

At Cubis Systems, we offer a faster, greener, and more efficient way to build underground infrastructure. Instead of carbon-intensive and inflexible methods like bricks and concrete, we manufacture sustainable plastics incorporating intelligent design features.

Our access chamber materials

-

High Density Polyethylene (HDPE)

- Largely composed of high-grade recycled material, and recyclable at end of life

- Used in: STAKKAbox™ JMF, STAKKAbox™ Fortress, MONObox™ POLYvault™, MONObox™ Carson

-

GRP (Glass Reinforced Polyester Resin)

- Provably low-carbon footprint compared to traditional materials

- Used in: STAKKAbox™ ULTIMA Connect, STAKKAbox™ ULTIMA, STAKKAbox™ RapidSTACK™

-

Polypropylene (PP)

- Composed of up to 100% recycled materials, and recyclable at end of life

- Used in: STAKKAbox™ Modula, STAKKAbox™ Hydrant, STAKKAbox™ Utility, STAKKAbox™ Toby

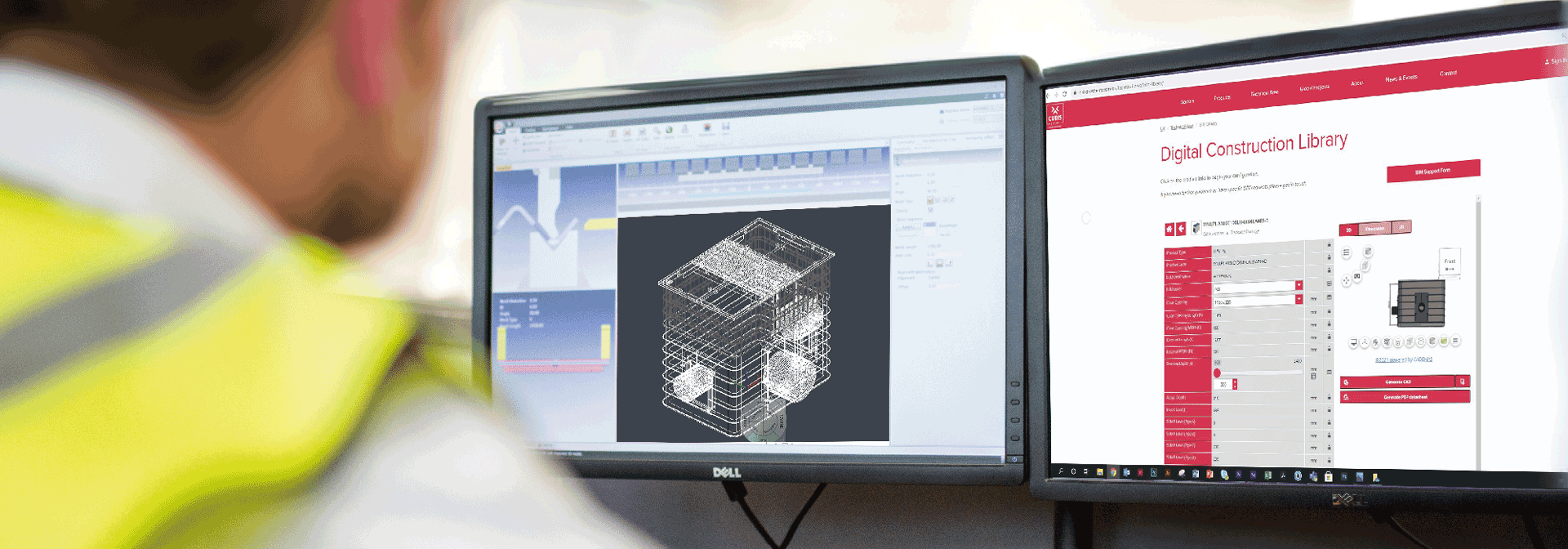

As a recent example, one client saved £235000, 282 tonnes of carbon, and 30% fewer chambers with our BIM-powered redesigns.

The overall impact

These benefits are tested and proven. Together, they add up to create a potential 80.7% carbon reduction across your project. (When using our modern solutions over the traditional concrete alternative.)

That’s a tangible reduction in your environmental impact, and a powerful tool for meeting regulatory targets and stakeholder expectations.

With carbon reporting, planning requirements, and sustainability KPIs under the microscope, the case for smarter material choices is clear. Our sustainable access chambers deliver on performance, installation efficiency, and long-term environmental responsibility.