HS2 Rail Infrastructure Upgrade

Case Study Details

Client

Skanska UK

Location

London, UK

Product

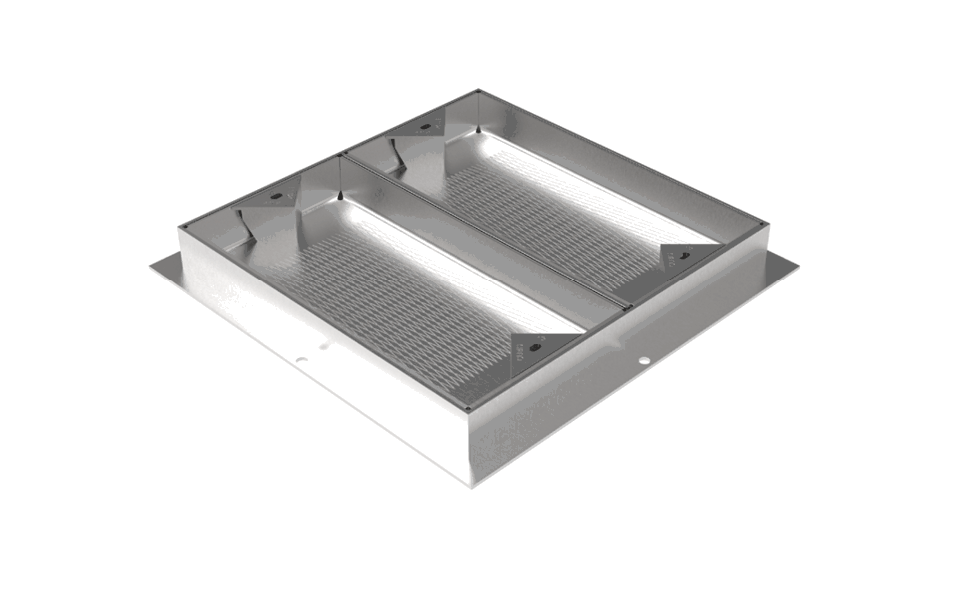

STAKKAbox™ ULTIMA Connect, AX-S™ Recessed Covers

Sector

Rail

Case Study

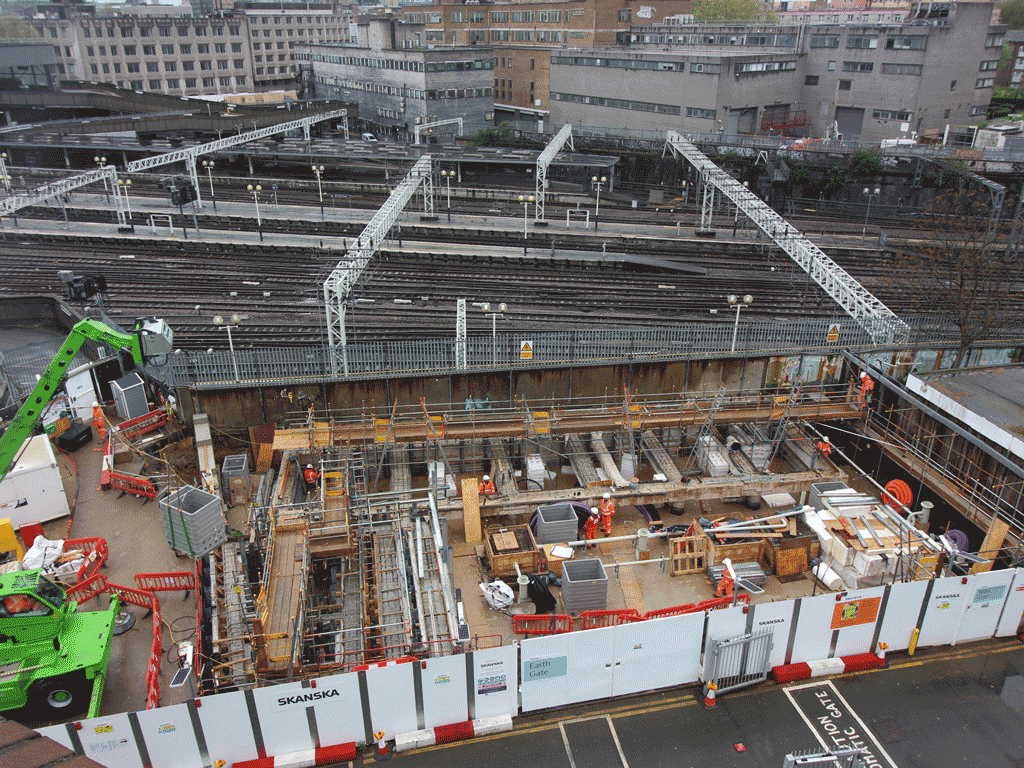

The vast scope of redevelopment to transform London Euston Station into the first modern, intercity transport hub for high-speed rail services is well underway. Euston Station is one of 4 stations that will be transformed ahead of the new High Speed 2 (HS2) rail line connecting London to the Midlands, the north of England and Scotland.

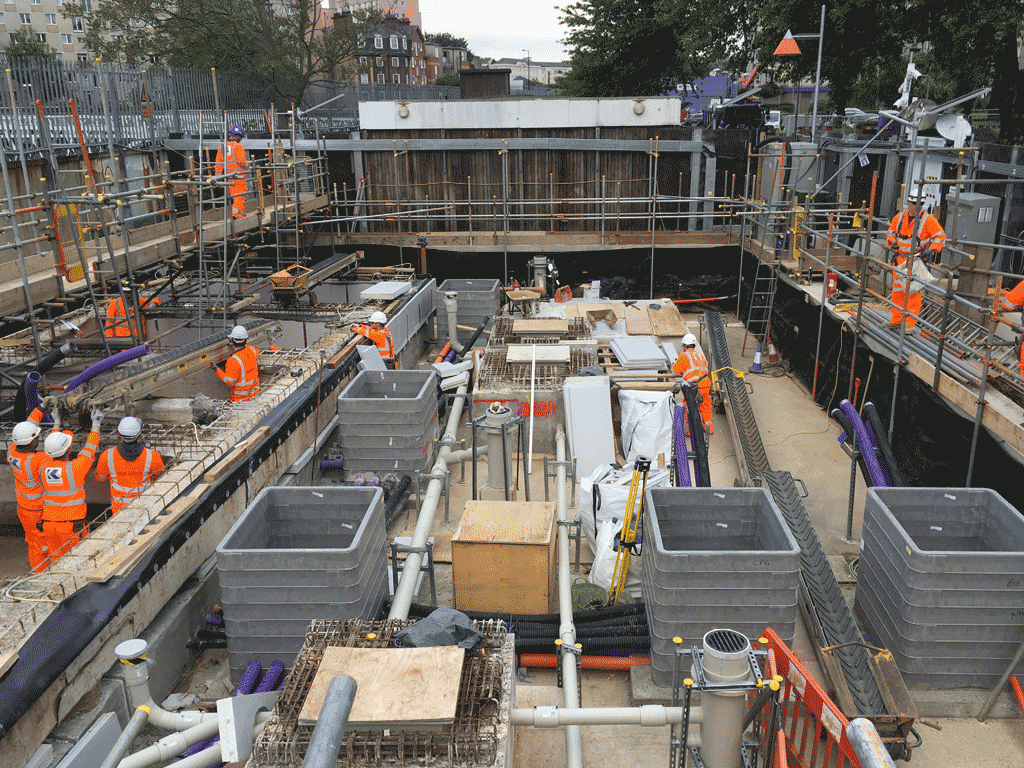

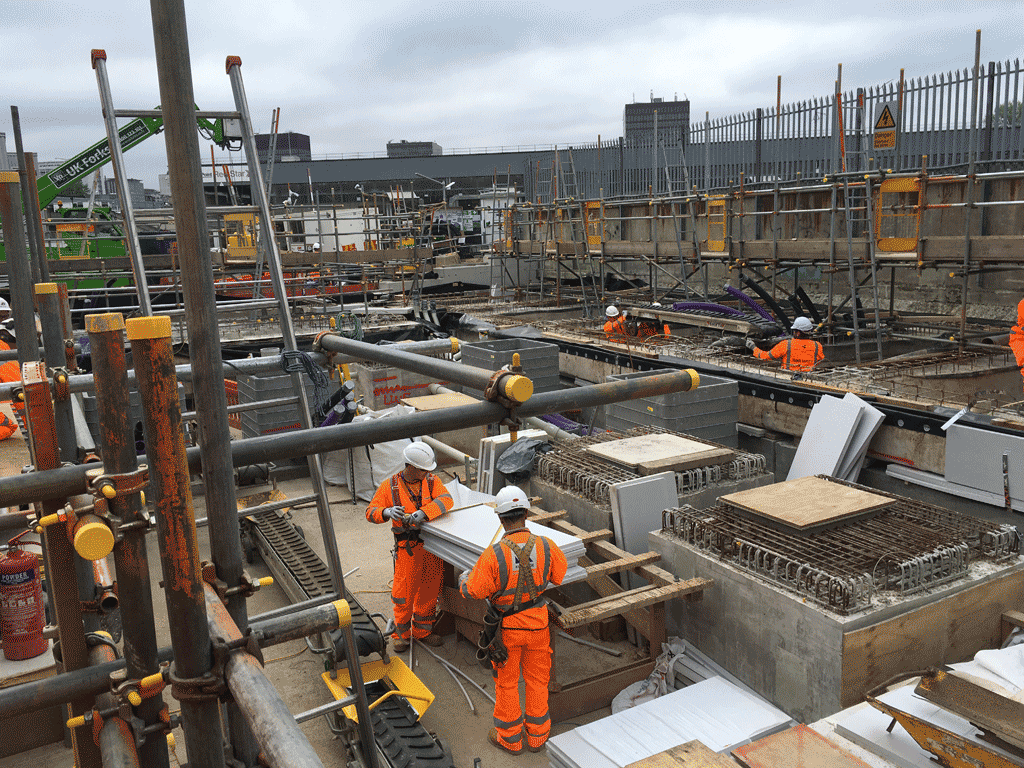

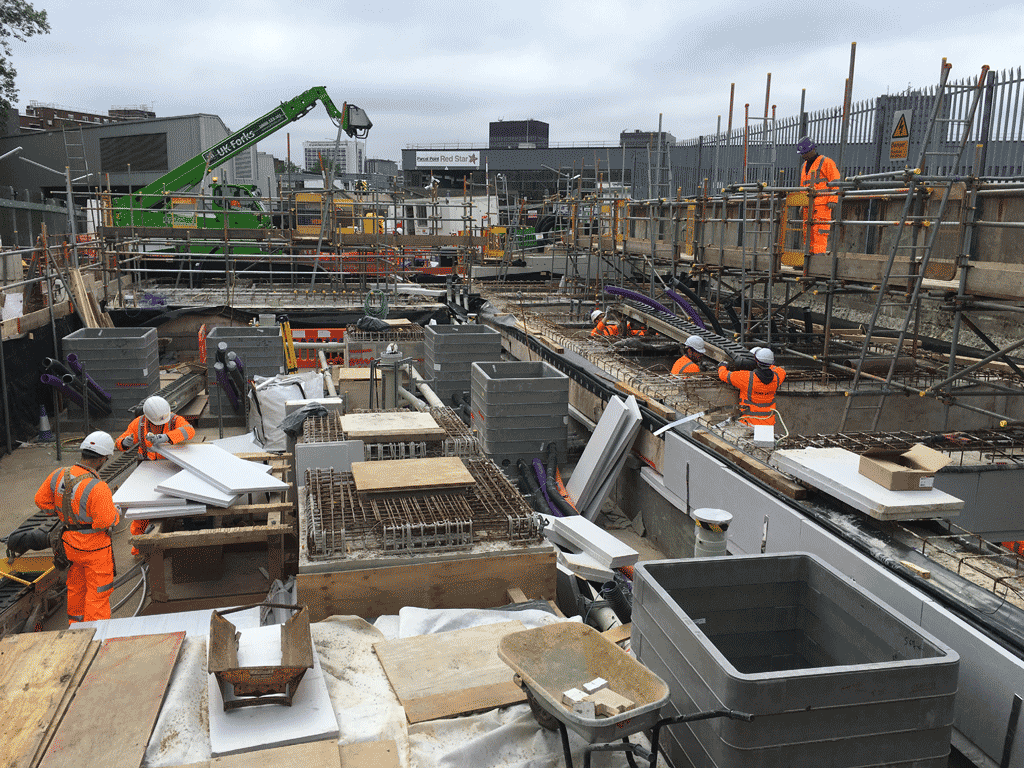

Network Rail and Skanska, on behalf of HS2 are delivering enabling works at the station and surrounding area, with the groundworks being subcontracted to Kilnbridge. This will see the eventual construction of a 25,260m² terminus, new high-speed platforms and improvements to the surrounding open public areas.

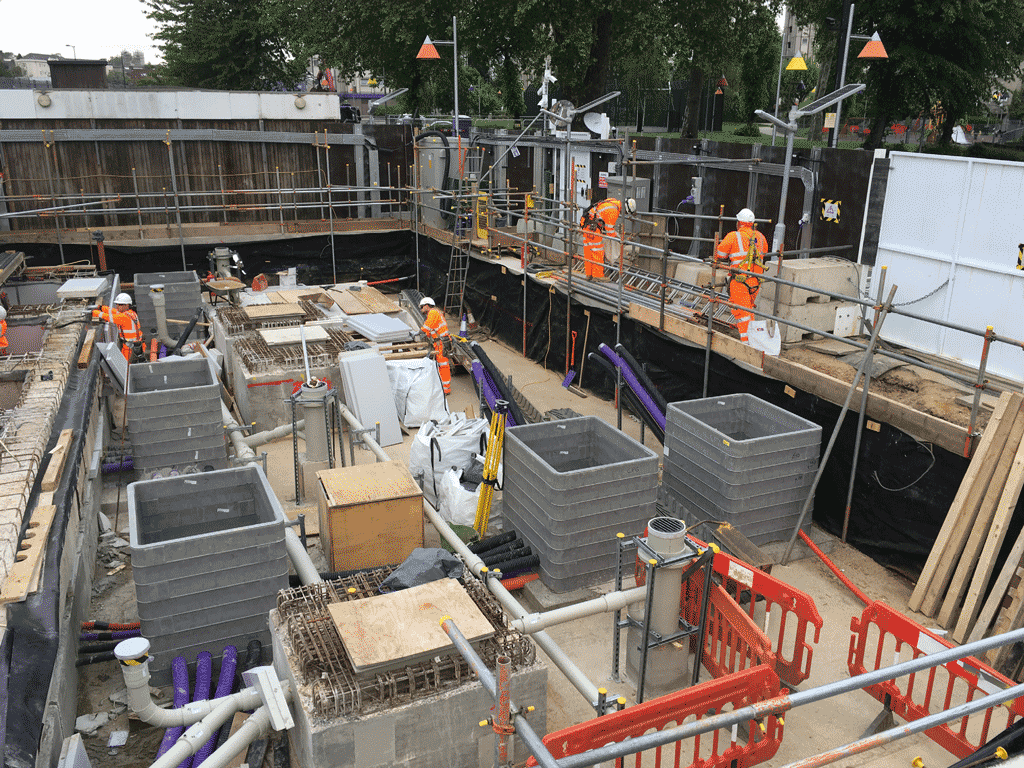

To enable the new Euston station development to take place, works have begun on constructing a new electrical substation that will assist in powering the station and its facilities. The new substation, located just off the main London Euston line at Barnby, has been erected to distribute both HV and LV power cables into the substation and onward to the track and station. The substation, like many new buildings in London, is located within a restricted area with limited access, storage and mobility.

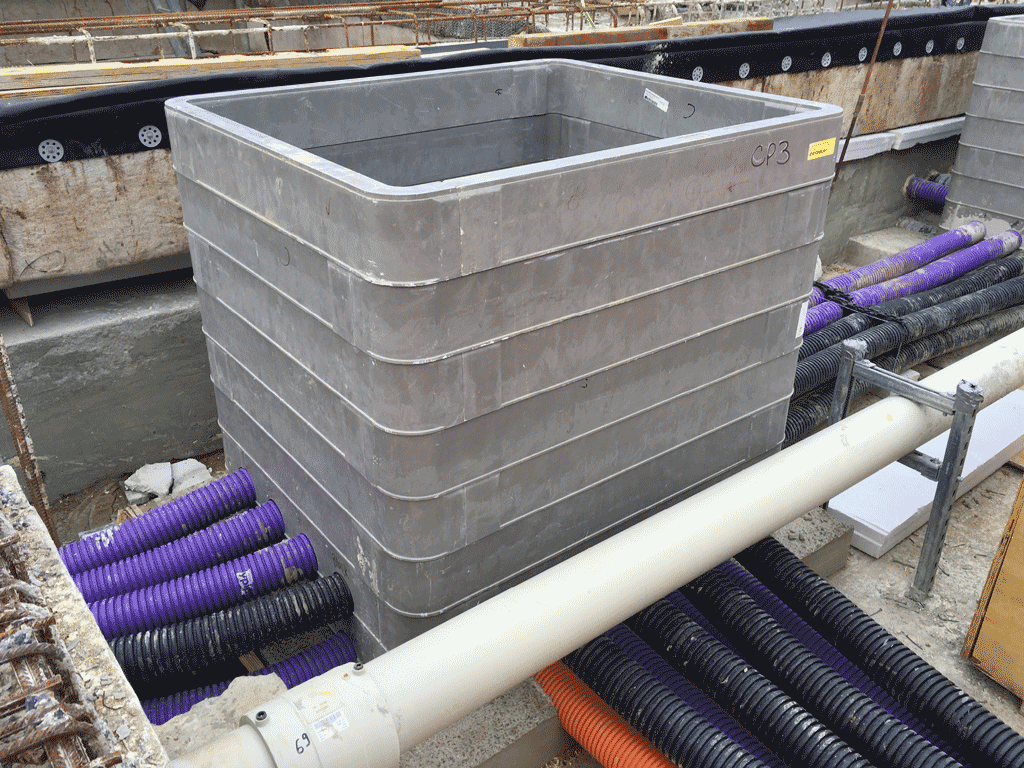

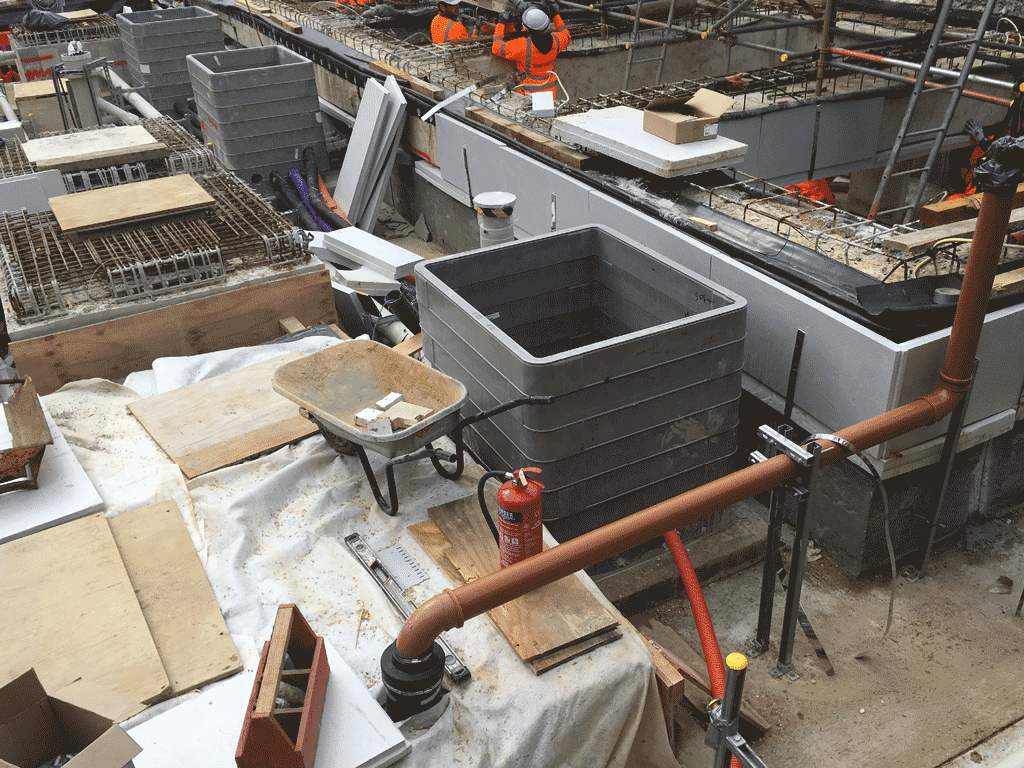

The project had a requirement for cable draw pits with easy accessibility for new power cables and in the future-proofing of the development for any new HS2 station and track cabling requirements. However, site conditions would not allow for a traditional concrete access chamber construction due weight and access restrictions. Cubis were approached to provide advice on our innovative, lightweight and modular access chamber range, STAKKAbox™ ULTIMA Connect.

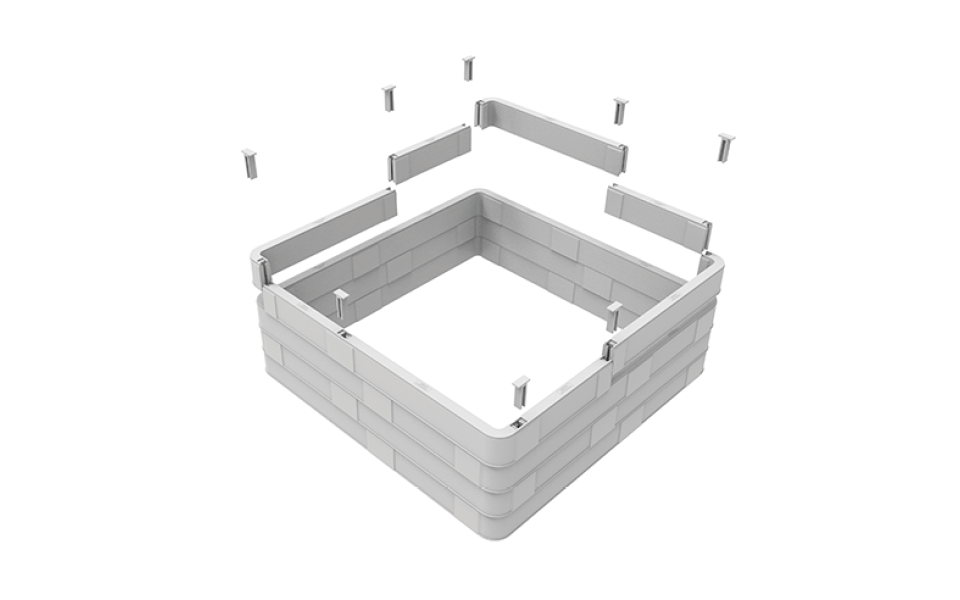

The team at Skanska worked with the Cubis Technical team to design and specify STAKKAbox™ ULTIMA Connect due to its lightweight and flexible onsite capabilities with the capacity to be installed manually without the need for skilled wet trades. The individual 150mm deep sections of twin-wall GRP that make up the ULTIMA Connect chamber system provided a lightweight, modular solution with components falling under 25kg making them suitable for a single person lift under manual handling regulations. With the added flexibility of being delivered to site with pre-drilled duct entries and the need only to reassemble the chamber components, the overall installation was significantly faster in comparison to conventional alternatives.

STAKKAbox™ ULTIMA Connect was designed and supplied to seamlessly integrate with Cubis’ B125 composite AX-S™ recessed access covers, providing a complete site chamber access and cover solution, while offering an improved aesthetic finish to the open public space, situated alongside the new substation. This integrated system offered a complete solution for the customer, reducing both time, health and safety risks and resulting in a significant overall cost saving.