Trade moulding with Cubis Systems

Let's bring your product to life

At Cubis, we offer advanced injection and compression moulding services to support your product development. Whether you're in construction, automotive, or electrical industries, we help you take your idea from sketch to full-scale production.

Our capabilities include:

-

Collaborative ideation & feasibility studies

We work closely with your team to shape early concepts and explore material and design options. Our engineers help assess technical and commercial viability from the outset, reducing risk and setting your project up for success.

-

End-to-end project management

Your project is managed through our structured New Product Introduction (NPI) and Advanced Project Management (APM) frameworks. This ensures smooth progress from design through to full-scale production, with clear milestones and accountability.

-

FEA and mould flow simulations

We carry out Finite Element Analysis and mould flow studies to predict how your design will behave during manufacture and in use. In turn, this helps optimise performance, reduce material waste, and prevent costly rework.

-

Rapid prototyping and stakeholder approvals

We provide functional prototypes quickly, enabling real-world testing, design validation, and early feedback before full tooling is committed - saving you time and cost.

-

Customised materials (inc. fire-resistant SMC/BMC)

We offer a wide selection of materials, including tailored SMC/BMC composites with varying fire, strength, and durability properties — ideal for demanding infrastructure environments.

-

Bespoke assembly and in-house QA

Need more than a moulded part? We design and build custom jigs and fixtures for assembly, and carry out rigorous in-house quality checks to ensure everything meets spec.

-

Certified to BSI9001 and BSI14001

We operate to internationally recognised standards for quality and environmental management. So, you can trust in our processes as much as our products.

We offer end-to-end control of the manufacturing process. Our scope covers:

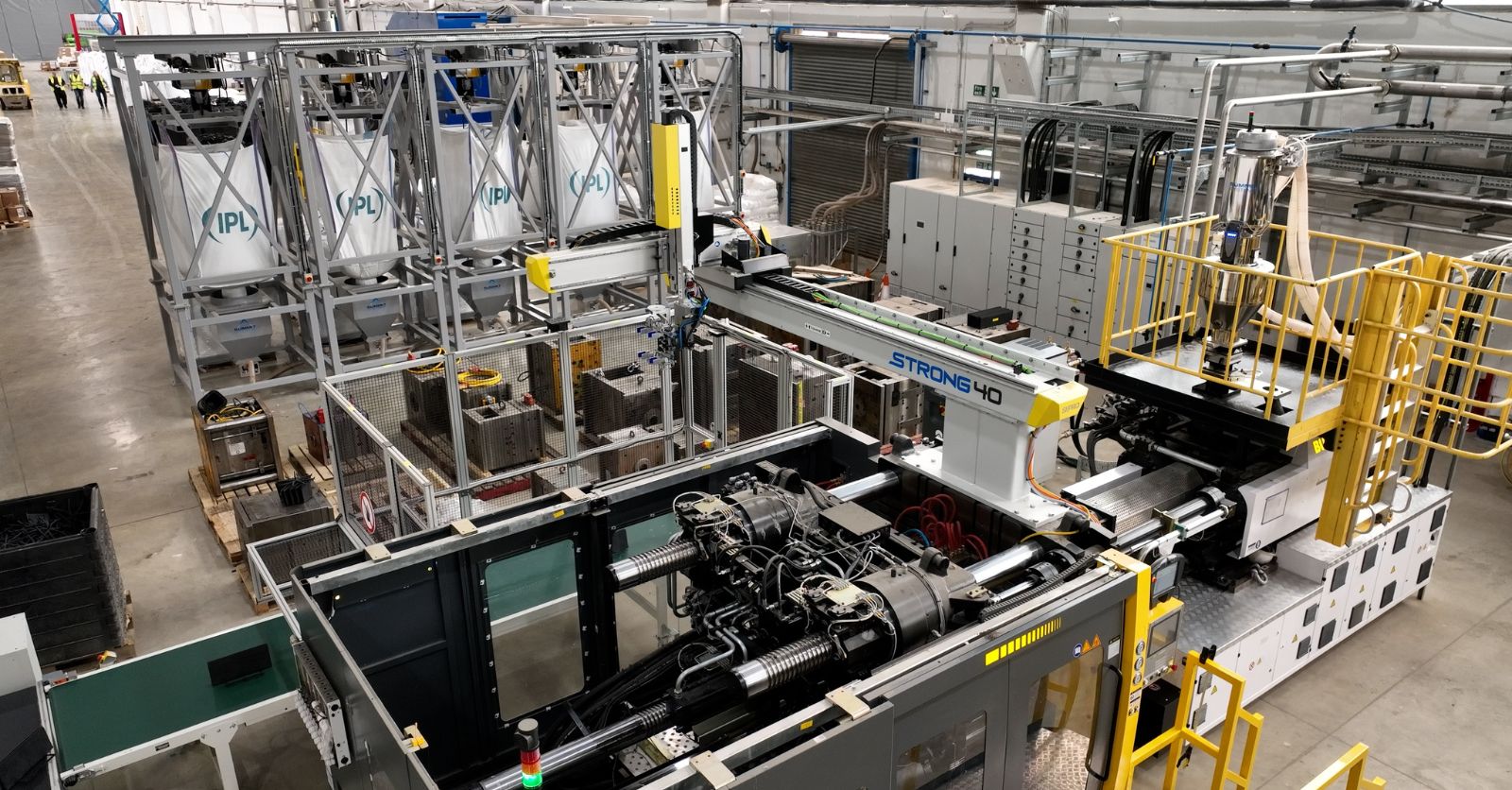

Injection moulding

Capacity snapshot:

- 8x state of the art 8 x injection mould machines

- Ranging from 130t – 1350t

- Robotic automation pick and place

- Shot capacity suitable for parts 0.42g – 9kg

- Suitable for LPDE, recycled polypropene, Nylon 6, and Acetal

Low pressure gas filled injection moulding

Capacity snapshot:

- 1 x 1000t LP material shot

- Capacity up to 76kg shot size

- Material HDPE gas filled

Compression moulding

Capacity snapshot

- 27 compression presses

- Tonnage 150t – 1200t

- Efficient mould tool steam heating

- Materials SMC & BMC (In house capability to produce BMC)

- SMC & BMC can be tailored for different levels of performance in fire properties

Assembly & quality assurance

We offer full assembly services for parts that require it, including the design and manufacture of bespoke jigs and fixtures to ensure precision and repeatability.

Our processes are backed by rigorous in-house quality control and fully certified to ISO standards, including:

- BSI 9001 – Quality Management

- BSI 14001 – Environmental Management

You get reliable, high-performance components - every time.

📍 Made in Britain

⚙️ Proven industrial capability

⚡ Rapid prototyping

🧪 Materials expertise

📝 Fit and functional tests

🦾 Short lead times

⚙️Flexible, tailored production

🏭 Seamless from concept to delivery

Our trade moulding process

-

➜ Step 1: Feasibility review

Following initial ideation, we assess your concept to ensure it is technically and commercially viable. This includes evaluating materials, performance requirements, and production feasibility.

-

➜ Step 2: Design & development

Once feasibility is confirmed, we begin the design phase. Your project is managed through our formal NPI (New Product Introduction) and APM (Advanced Project Management) processes, with a dedicated team assigned from start to finish.

-

➜ Step 3: Engineering analysis

We carry out detailed Finite Element Analysis (FEA) and, if required, mould flow simulations. This helps us understand how your product will behave with the selected material — reducing risk and improving reliability before tooling.

-

➜ Step 4: Prototyping & testing

We produce rapid prototypes to validate fit, function, and performance. This enables practical testing and stakeholder feedback ahead of final tooling.

-

➜ Step 5: Tooling & pre-production approval

Once the design is approved, we work with trusted toolmakers in the UK and Asia to produce production-ready tools. Initial moulded samples are delivered for final approval.

-

➜ Step 6: Full-scale manufacturing

With tooling signed off, we move into full production using our in-house injection and compression moulding capabilities — delivering consistent quality, reduced lead times, and scalable output.