[COMING SOON] D400 composite cover

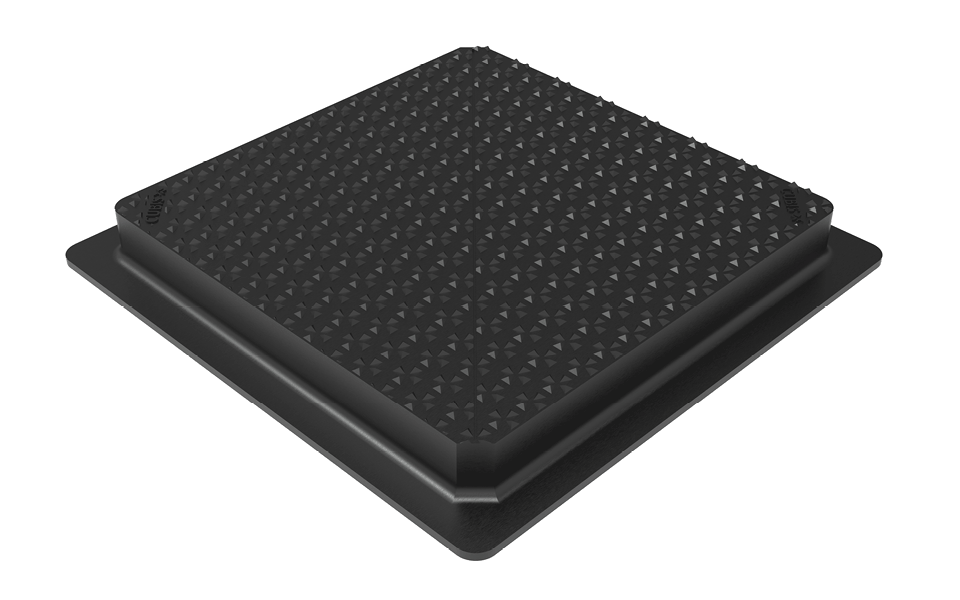

Get heavy-duty performance from a lightweight 25kg cover.

Our new D400 composite access cover range offers a significantly safer and easier installation option than traditional ductile iron covers – without compromising on strength.

The weight and inflexibility of existing solutions – precast concrete cover slabs, ductile iron covers – can pose installation setbacks.

Instead, our D400 composite system introduces a smarter alternative based on modularity, easy handling, and on-site adaptability.

Coming in early 2026 - get in touch for more information.

Features & benefits

Full access without machinery

D400 strength within a compact, lightweight cover that doesn't need to be hinged or gas-assisted to lift.

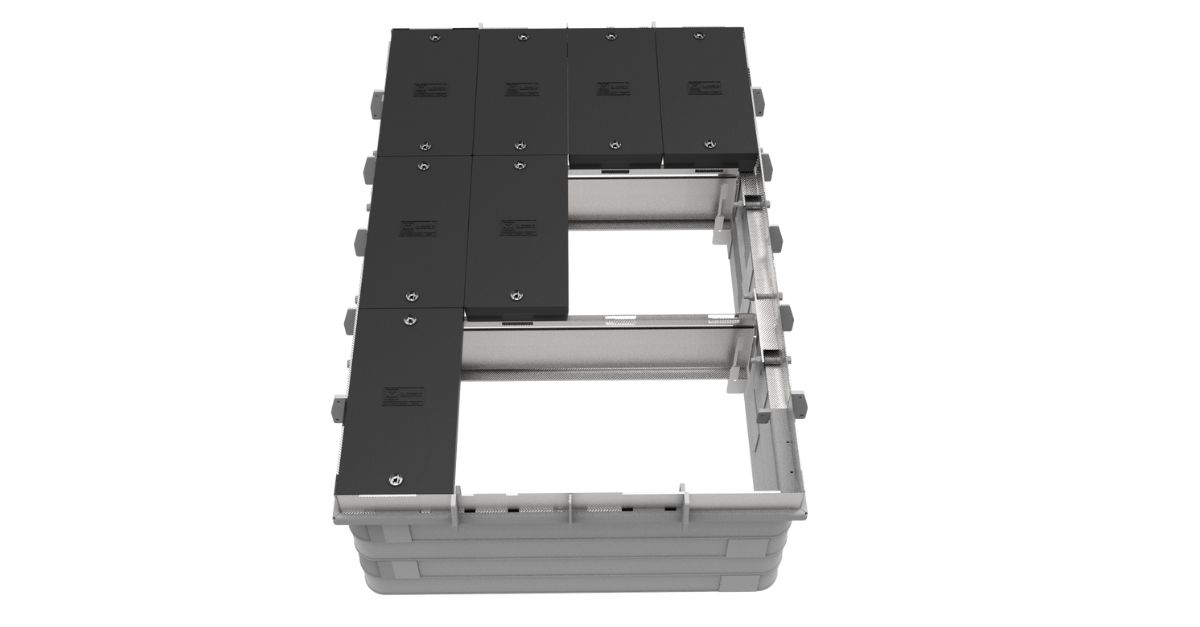

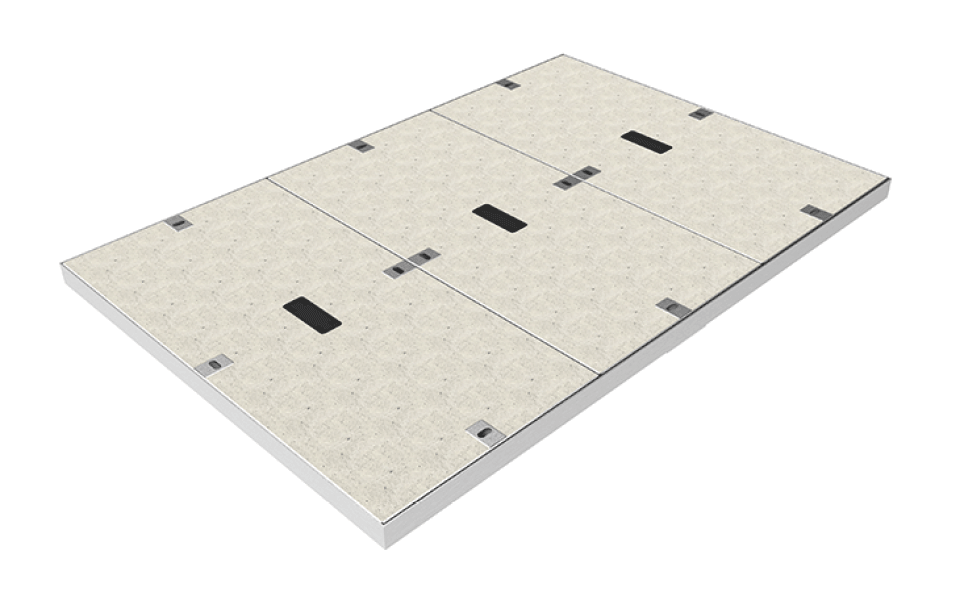

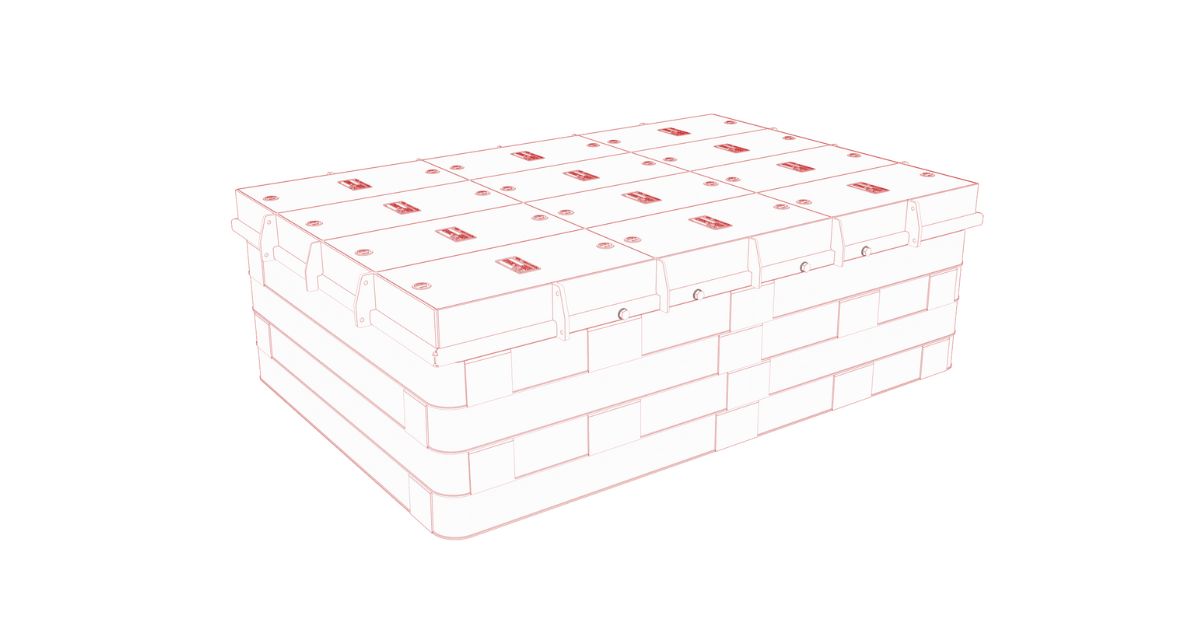

Flexible, multispan design

Support multiple covers within our multispan frame – giving you adaptability across varying site conditions and chamber configurations.

Safe manual handling

At 25kg per access cover, you can install quickly and safely by hand – reducing risk, plant, and installation time.

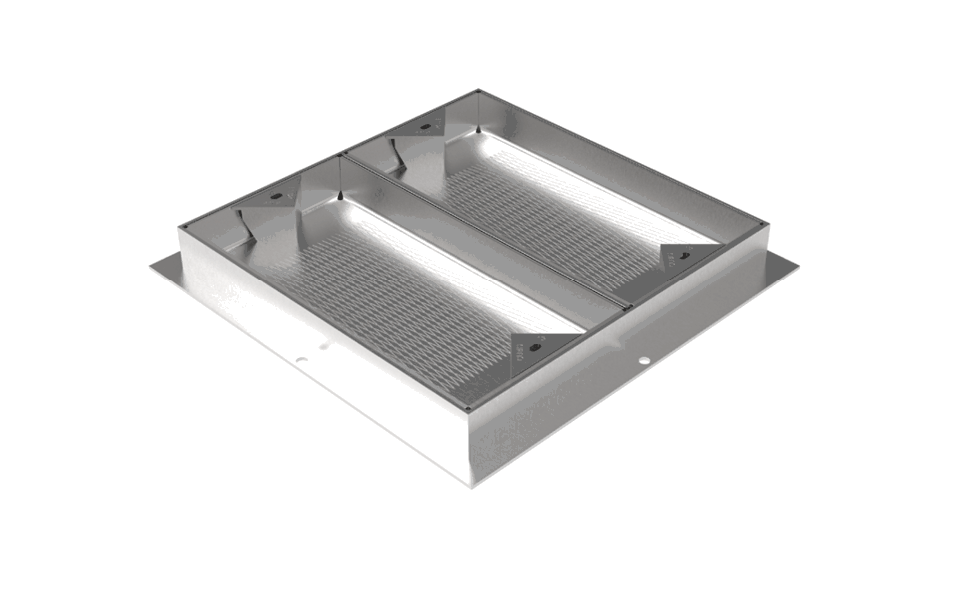

Modular construction

Sits within a fabricated steel frame built up of modular components – flat-packable for added site convenience.

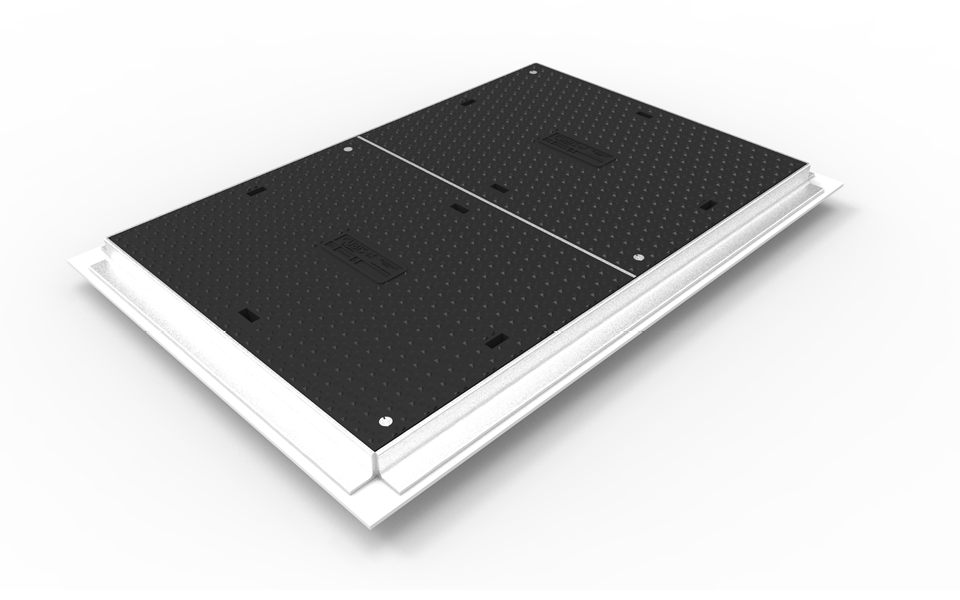

Self-locking mechanism

Supplied with a dual-purpose lifting and locking aid – simply lock the cover via a quarter turn locking latch.

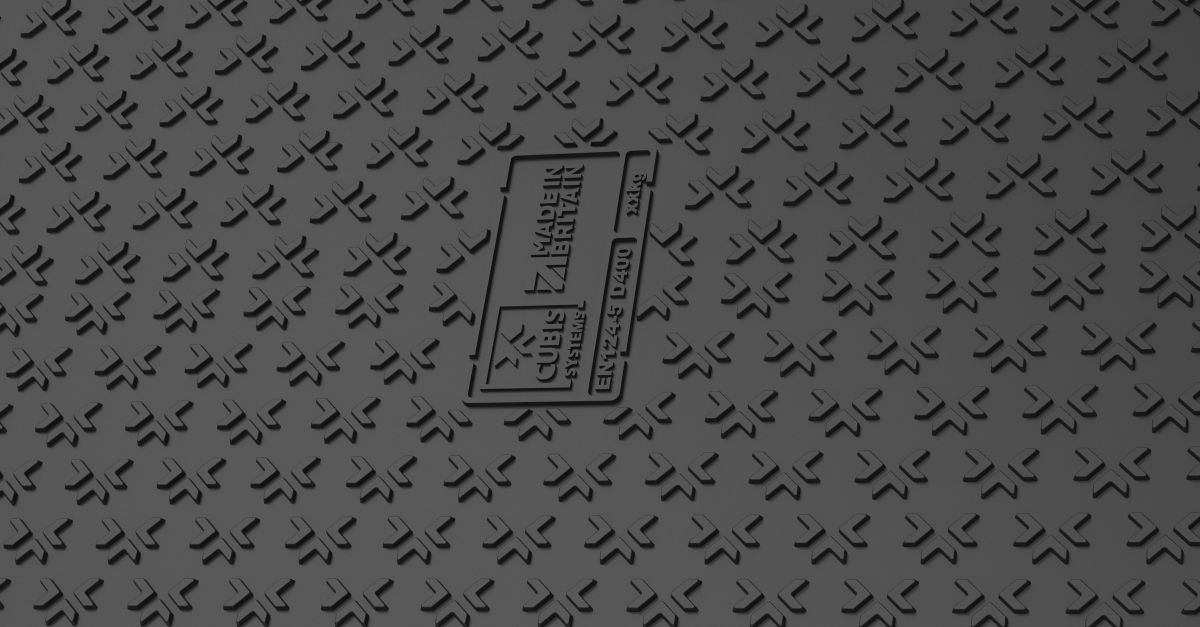

Anti-slip & customisable design

Incorporates our bespoke, non-slip tread pattern – with allocated space to hold any custom badging options for the asset owner.

Maximises clear opening spaces

Floating beam design means that the cover and its system components are easily removable to maximise working areas.

Seamless installation

Cover and frame options offer compatibility with our STAKKAbox™ access chamber offerings for a coordinated, structural solution.

How it works

Our D400 access cover range includes a modular steel frame, floating beams, and the composite access cover – all designed to integrate with our STAKKAbox™ chambers. To install, fit the frame and its assembly components (corner and length pieces) to the chamber top. Floating beams then slot into receivers independent of the chamber to support the composite cover(s).

Available sizes

Modular, multispan design allows for the covering of large or complex areas in a variety of sizes, for a variety of applications.

• Frame ranges from 1500x1500mm to 6300x3100 C/O (100mm total seating)

• Frame length increases in 800mm increments (driven by cover dimensions)

• Frame span increase in 400mm increments (driven by cover dimensions)

• Cover dimensions sit at 800x400mm per cover, with a 120mm depth

Properties & materials

Our D400 covers are built from lightweight but high-strength composite materials. The complete system is designed and tested in accordance with EN 124-5 for D400 loading.

- Covers manufactured using Resin Transfer Moulding (RTM) with integrated foam cores

- Frames, beam and corner/length pieces are manufactured from rolled steel section in compliance with BS1449

- Galvanised in compliance with BS EN ISO 1461

- D400 loading capacity – central and offset load position