From concrete to composites

A new vision for UK rail assets

The next 20 years of UK rail will be shaped by the decisions we make now. From replacing legacy materials to rethinking maintenance strategies, the shift toward sustainability is already underway.

But what will it take to truly optimise our rail assets?

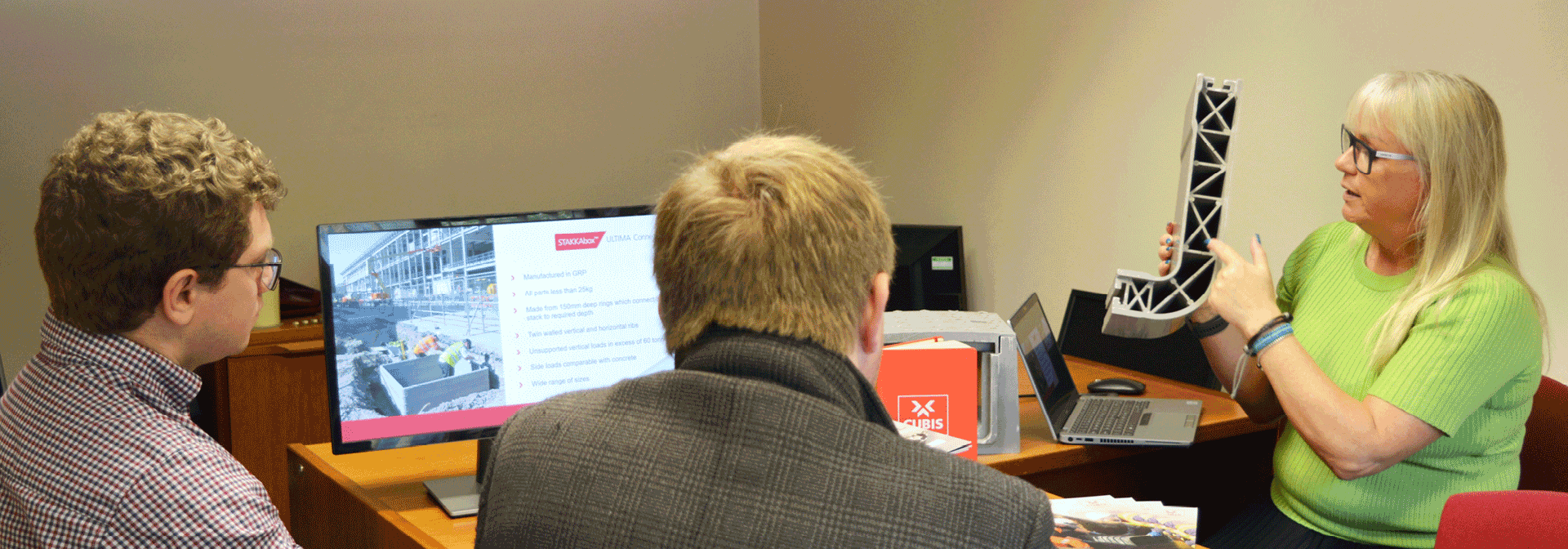

We sat down with Ryan Cunliffe, one of our resident rail sector experts here at Cubis Systems, to explore the practical challenges and opportunities ahead.

First, could you introduce yourself?

I’m Ryan Cunliffe, and I’m Business Development Manager for Rail here at Cubis. I started my career in rail groundworks, and then gradually progressed into technical sales as my skills and experience evolved.

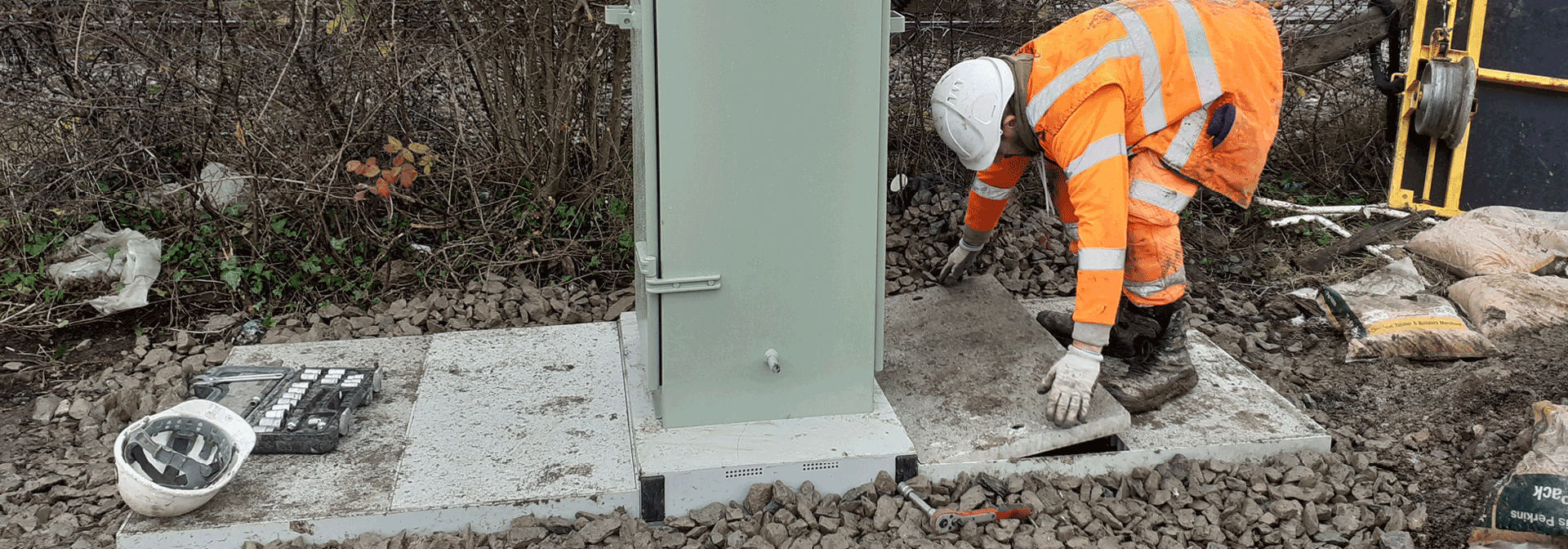

This hands-on, on-site background has given me a full 360° understanding of rail infrastructure projects. My roots in groundworks mean that I understand the pain points of installers and contractors, while my role in business development also sees me working closely with designers and asset owners.

Cubis was a natural employment choice for me. I was already familiar with installing the products from my early career years, and knew first-hand their advantages. Now, in my position as BDM, I feel proud to be able to introduce these solutions to partners and improve their project outcomes.

Next, could you tell us more about Cubis Systems and its rail capabilities?

Cubis Systems is a leading international rail infrastructure provider. We’re the sustainable partner of choice for light rail and major rail infrastructure projects across the UK, France, Scandinavia, North America and Australia.

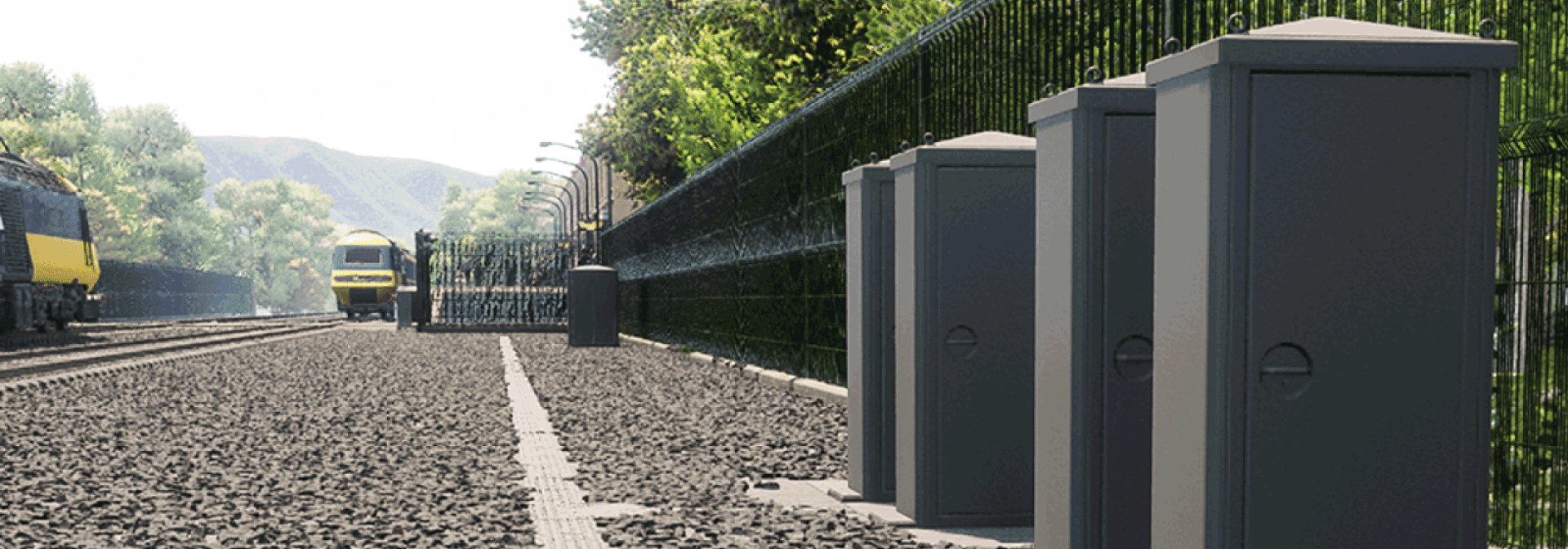

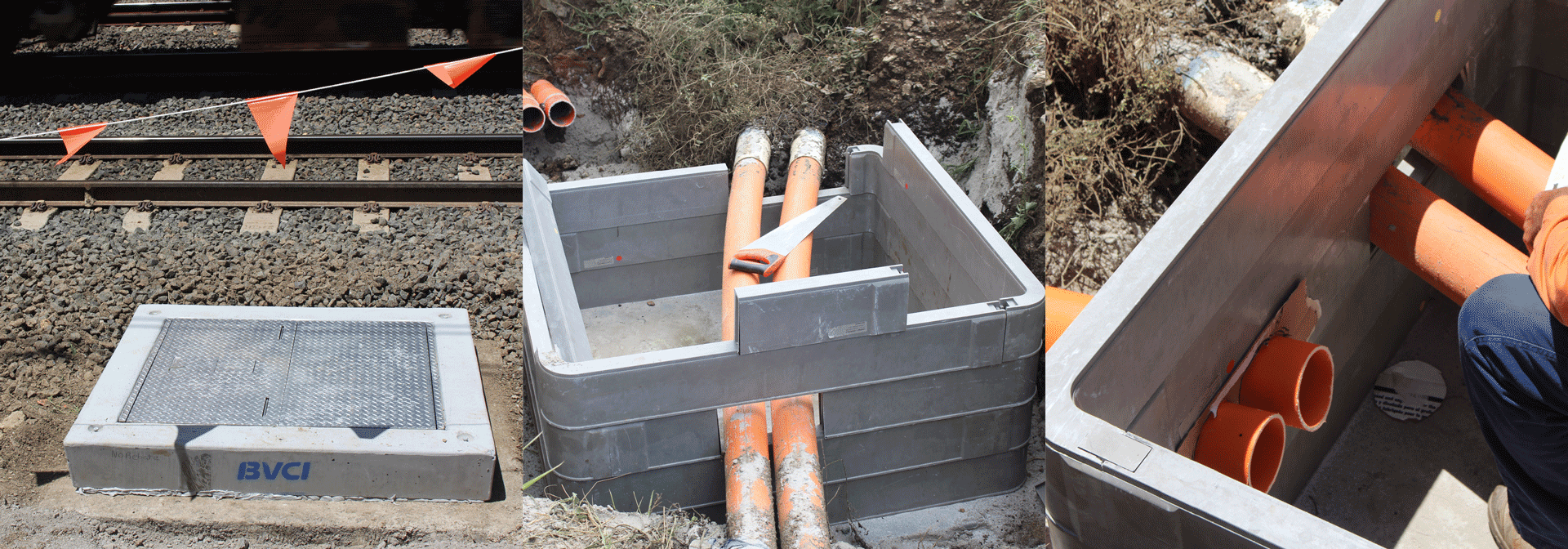

Specifically, we specialise in efficient, modern-day access systems for telecoms, drainage, trackside signalling, power and cabling. Our intelligent technical design applies across composite access chambers, access covers and cable protection features. Importantly, these solutions are modular, scalable and lightweight. All of which means that they can be built-on site – simply safely and with speed of installation.

This formula has proved winning for over fifteen years. Customers such as Network Rail (UK) and SNCF (France) have trusted our integrated product approach, direct delivery and innovative partnering.

It’s impossible to talk about Cubis without touching on sustainability. Our solutions are designed to significantly reduce carbon emissions and enhance project efficiency. The reduction in concrete systems through our lightweight, GRP alternative results in an 80.7% carbon reduction.

In short, Cubis is an industry leader, and our solutions are actively tackling rail infrastructure challenges head-on.

What is your USP in the rail sector?

Perhaps most obviously, we offer an integrated systems approach, where all products create a seamless integration. We don’t just manufacture products here at Cubis. Working with us means getting a full product design to production service – including a free digital BIM configuration tool.

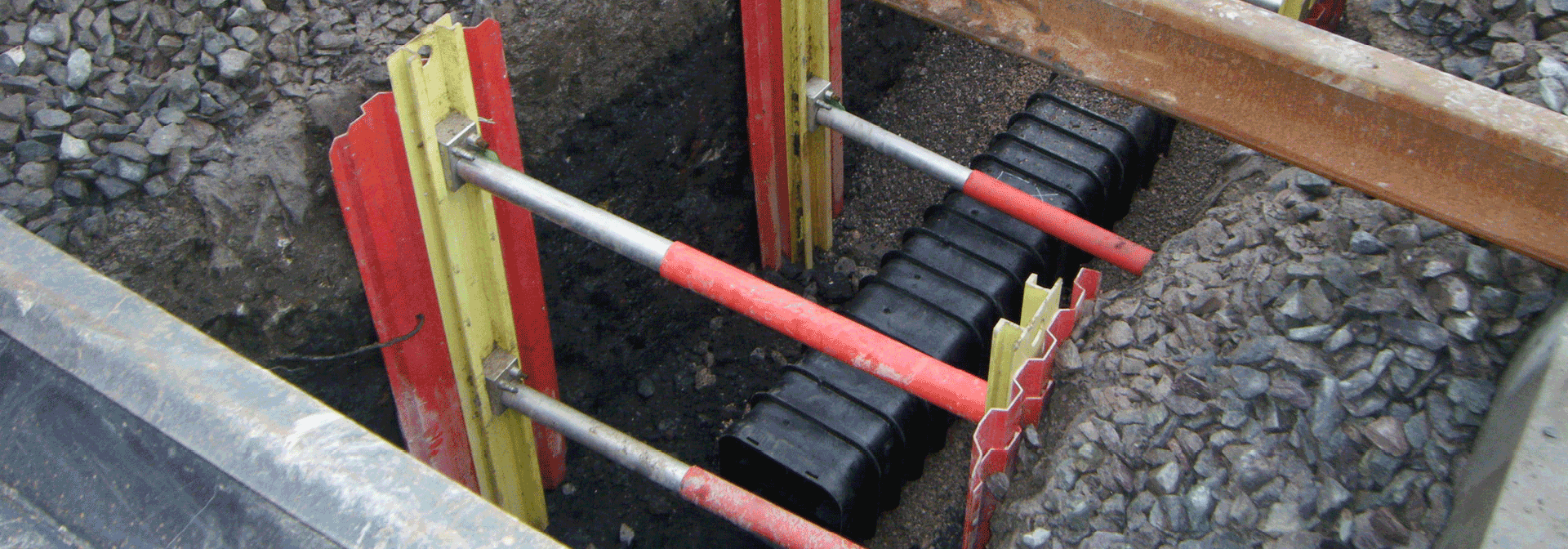

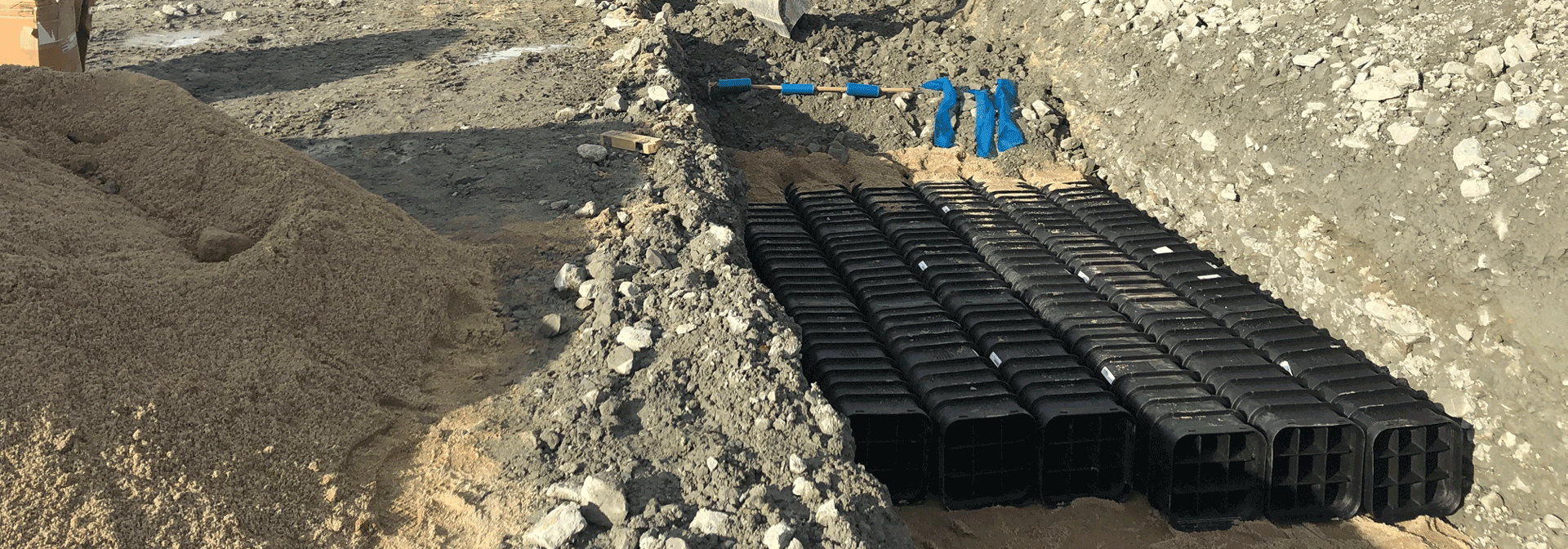

This isn’t to say that the products themselves aren’t uniquely beneficial – far from it. We supply lightweight but high strength composite products that are scalable, modular, and built with superior Glass Reinforced Polyester Resin. This makes for a highly flexible – but robust – solution that is fast and easy to install. For rail, we encompass multiple adaptable applications spanning under-track crossings, buried cable route systems, drainage catch pits, fixed telecommunications network solutions, and more.

Aside from their lightness and flexibility, another massive USP to our solutions is that they are made in Ireland and GB. So, as well as their innate sustainability, the green supply chain implications of using a UK and Ireland manufacturer are also obvious.

Architects, specifiers, and developers need not simply take our word on these sustainability USPs. To help them make better informed carbon decisions, we’ve also compiled a comprehensive library of Environmental Product Declarations (EPDs) for all our products.

Combined, these USPs offer consistently proven time, cost-saving, flexibility, and sustainability benefits to our customers.

How committed are you to sustainability in the rail sector, and what is your approach to sourcing materials?

As we’ve touched on, sustainability is at the heart of everything we do here at Cubis. To focus on how we source materials, we prioritise the use of recycled materials such as polypropylene (PP) and high-density polyethylene (HDPE) in the production of our access chambers, cable protection systems, and other infrastructure solutions.

These materials are not only environmentally friendly but also offer a longer operational lifespan. In turn, this durability reduces the need for frequent replacements and minimises waste.

Once the products have reached the end of their life, they can be fully recycled – further contributing to a circular economy.

Finally, in addition to using recycled materials, we are committed to reducing the demand for virgin raw materials. Our UK site has successfully achieved up to 100% recycled PP in its products, and our operations in the Republic of Ireland have been able to incorporate 80-100% recycled HDPE through investment in on-site material processors.

Could you share some of the key projects you have been part of over the years?

It would be nice to share a close-to-home example with you. Although we operate worldwide, railway renewals taking place across Northern Ireland recently afforded us the opportunity to work on several local projects. One of these was located less than two miles from our Head Offices and manufacturing site in Lurgan, Northern Ireland.

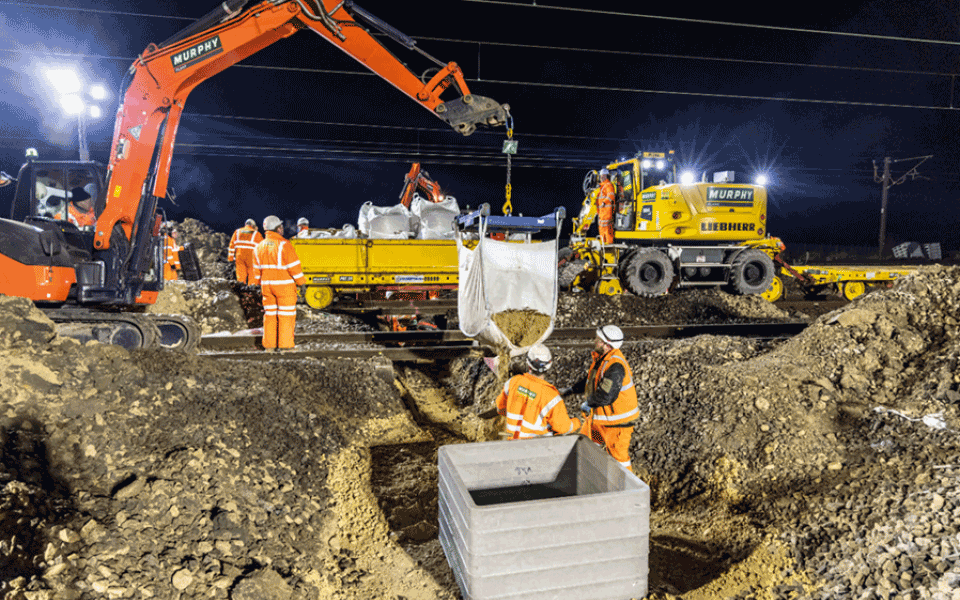

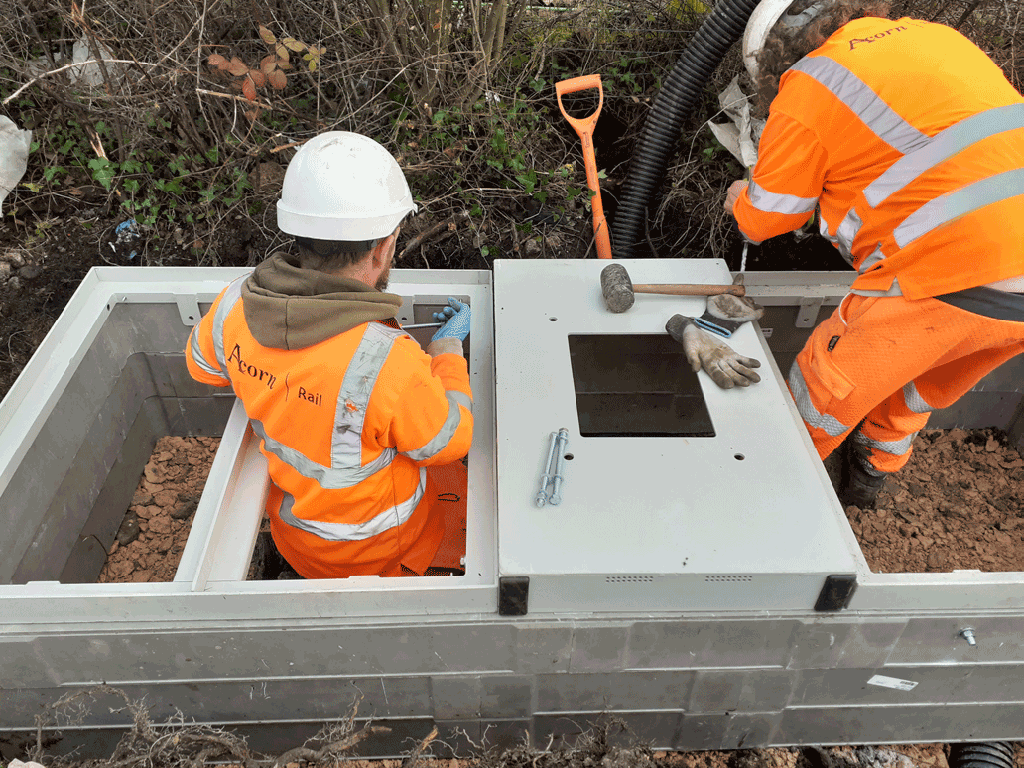

The project entailed delivering vital renewals and upgrades of nearly 9km of existing signalling and telecoms infrastructure. This included the construction of retaining walls in several locations, a new continuous duct route, and full lineside cable renewals. Cubis continuously supported the project through the supply of our network access chamber system STAKKAbox™ ULTIMA, our cable protection system MULTIduct™, and our lightweight troughing system PROtrough.

A study on the use of PROtrough concluded that, in comparison to a concrete alternative, PROtrough can offer an 80% reduction in the number of lorries required to transport 10,000 units of cable troughing from manufacturer to site.

So, this project is a great example of how we can provide the best solution due to being lightweight, fast to install, and easy to transport.

“What sets Cubis products apart is how easy they are to work with. Based on a T3 possession (when working hours are between 00:30- 04:45) on average we were able to install over 66 units of Cubis’ 6-way MULTIduct™ and at least one chamber per shift.” Lead engineers, Lurgan project

When a client approaches you with a specific issue, what process do you follow to devise a solution?

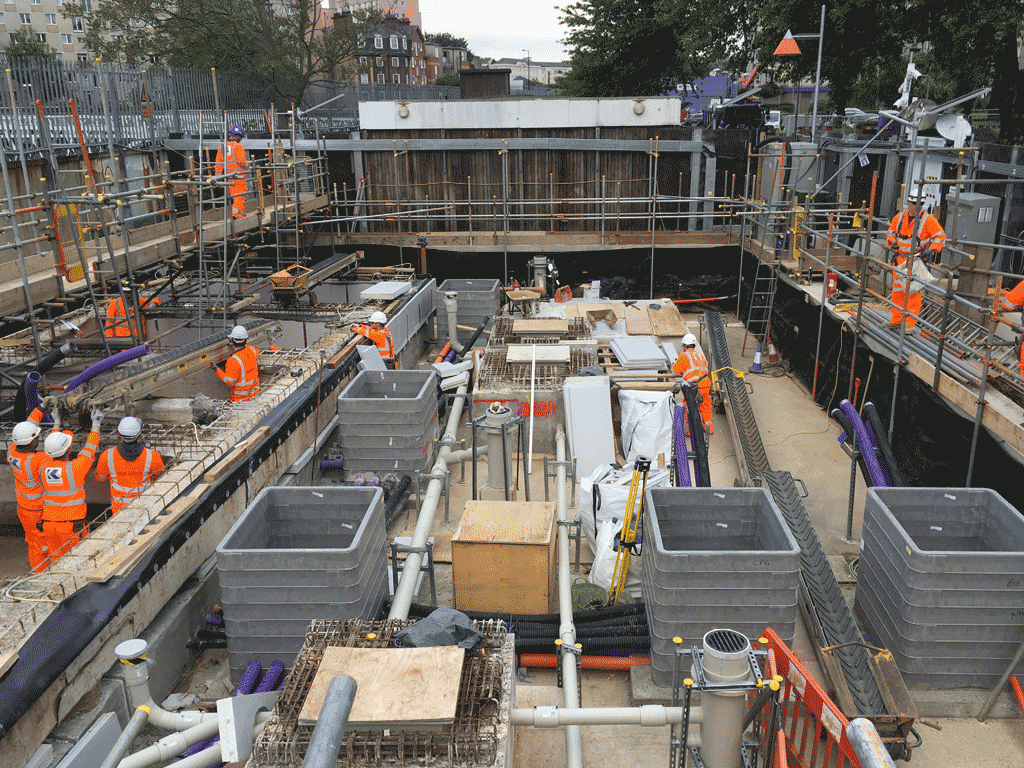

As standard, we collaborate with the designers to offer a suitable solution using our BIM tool. Another real-world example will serve as the best illustration of our approach. Recently, we worked with our client to redesign a critical rail infrastructure project – delivering them significant financial, environmental, and time-saving benefits.

Using our BIM-powered redesign, we replaced traditional concrete chambers and ducting with innovative Cubis Systems products like STAKKAbox™, PROtrough, and Multiduct™. By switching from traditional ducting to Cubis Multiduct™, the project achieved £235k savings on ducting and installation costs (a 48% reduction), and 282 tonnes of CO2 savings (a 75% reduction).

Then, in terms of chamber optimisation, the move from precast concrete chambers to Cubis Systems chambers resulted in a 30% reduction in the number of chambers required. This saved 25 tonnes of CO2 savings due to material efficiencies, and an additional 85 tonnes of CO2 savings from eliminating precast concrete.

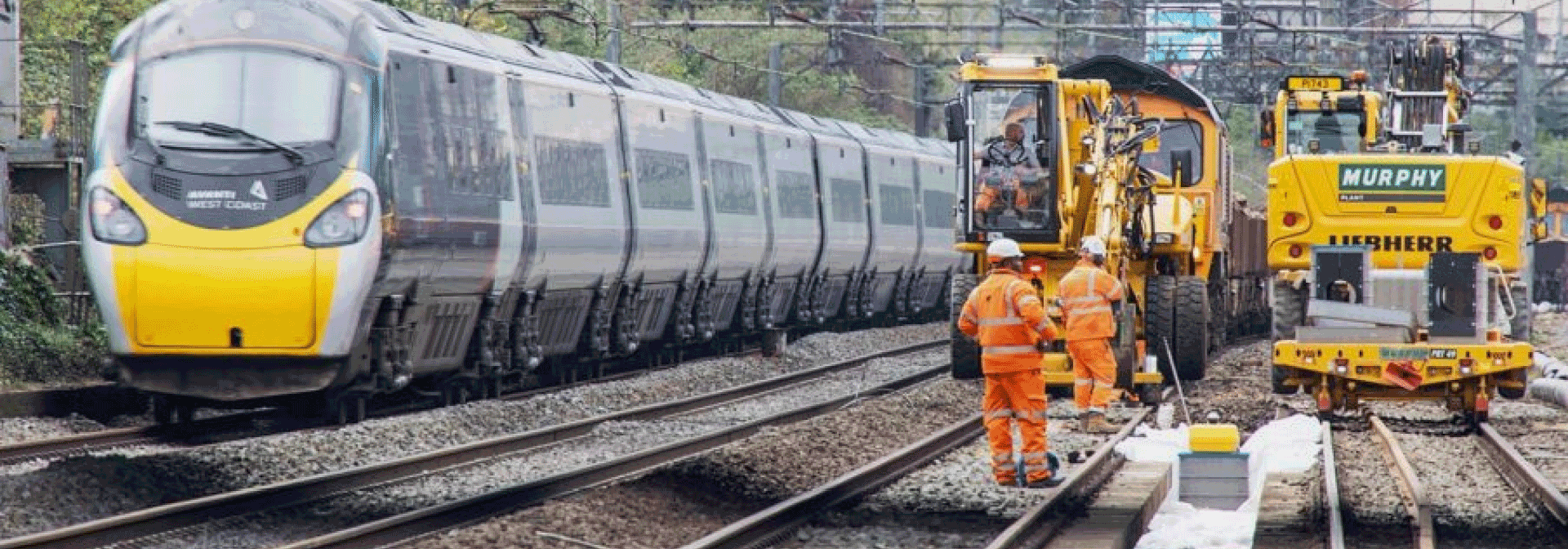

Plus, the redesigned plan also cut weeks off installation time. Disruption was reduced, safety was enhanced, and project delivery was accelerated.

What do you consider to be the most pressing challenge in the rail industry today?

The UK rail network is aging. Many parts of the rail network we rely on to this day were built between 1850 and 1920. So, as per the Lurgan project we mentioned earlier, significant investment in renewals and maintenance is required to keep services running smoothly.

While maintenance is essential, it can be challenging to keep up with the demands of a growing network. This is precisely where it becomes important to focus on forward-thinking solutions.

We now know that traditional concrete is not only problematic regarding the UK’s net-zero goals, but also vulnerable to chemical corrosion over time. Modern GRP access chambers – like those manufactured by Cubis – far outperform traditional construction materials in chemical resistance. This ensures a longer lifespan for the chambers, reducing the need for costly maintenance and replacements over time.

Simply put, to keep up with today’s needs, rail infrastructure projects need to prioritise speed, modularity, safety, and sustainability.

How can we optimise the use of rail assets, and what is your vision for rail in the next 10 or 20 years?

The reduction of concrete is key in optimising rail assets. Traditional construction materials, particularly concrete and steel, are resource-intensive to produce and have a high carbon footprint.

Concrete, for example, is responsible for between 4-8% of global CO2 emissions. In fact, if the cement industry were a country, it would be the world's third or fourth-largest emitter of carbon dioxide. The industry’s reliance on these materials contributes significantly to environmental degradation.

My vision is for the replacement of traditional concrete access systems with sustainable GRP alternatives.

Looking more closely to home, I’d also like to see the adoption of GRP solutions that are made in Ireland and Great Britain. As well as supporting local manufacturing, this would offer a dual sustainability boon. The materials themselves are sustainable, and the use of a local supply chain reduces carbon emissions. It’s a win-win scenario for UK rail.