Sports Centre Water Meter Installation

Case Study Details

Client

The Sleeman Sports Centre

Location

Queensland, Australia

Product

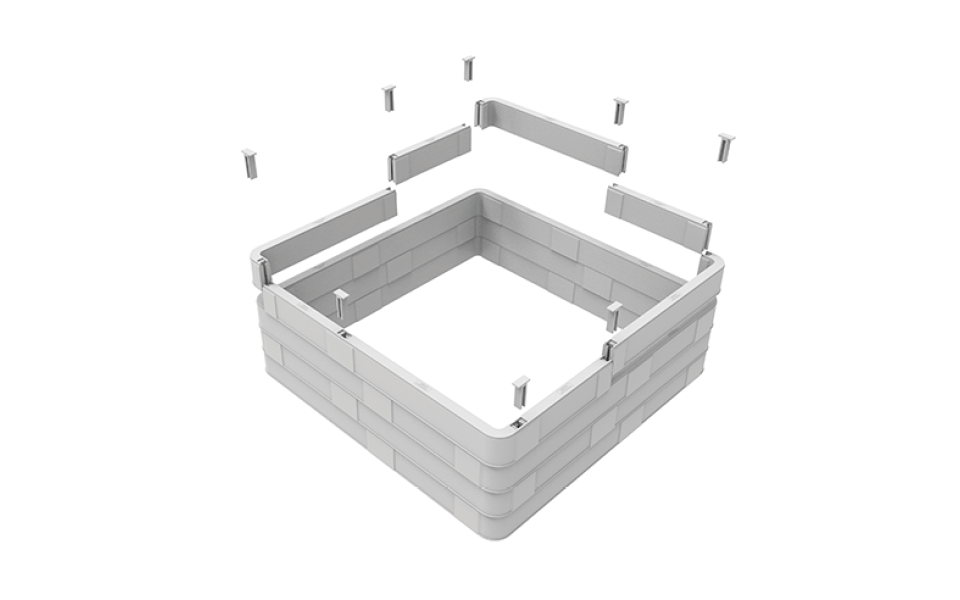

STAKKAbox™ ULTIMA Connect, Concrete Cover Slab

Sector

Water

Case Study

The Sleeman Sports Centre is one of Queensland’s premier sporting venues that recently hosted the Track Cycling Event for the 2018 Gold Coast Commonwealth Games (GC2018).

As part of a water meter installation for the centre’s existing water infrastructure, Cubis Systems were approached to provide an underground network access solution for asset protection.

Project Challenges

- Accommodate existing infrastructure

- Restricted installation timeframe

- Minimum Class B load rating (AS3996)

Due to a strict timeframe for installation of the new flow meter equipment and access chamber system, the contractor required an efficient and reliable alternative to the traditional cast in-situ concrete option. With a strong history of successful projects together, the contractor approached Cubis for a specialised, custom-engineered solution to meet their project requirements.

Cubis Solution

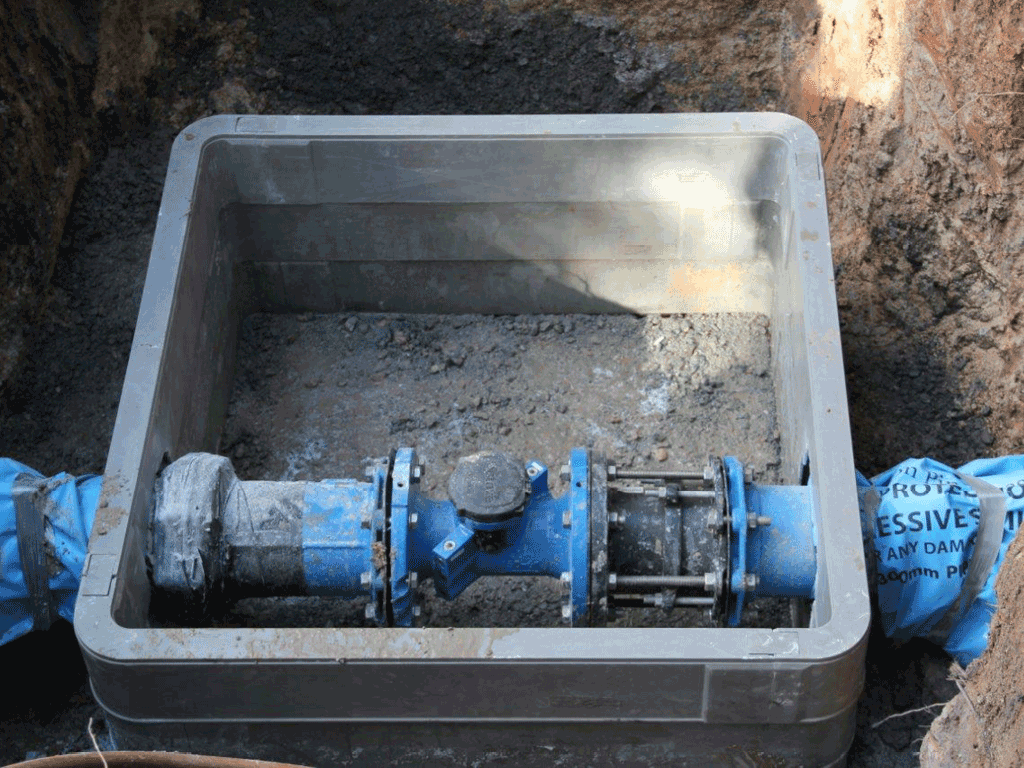

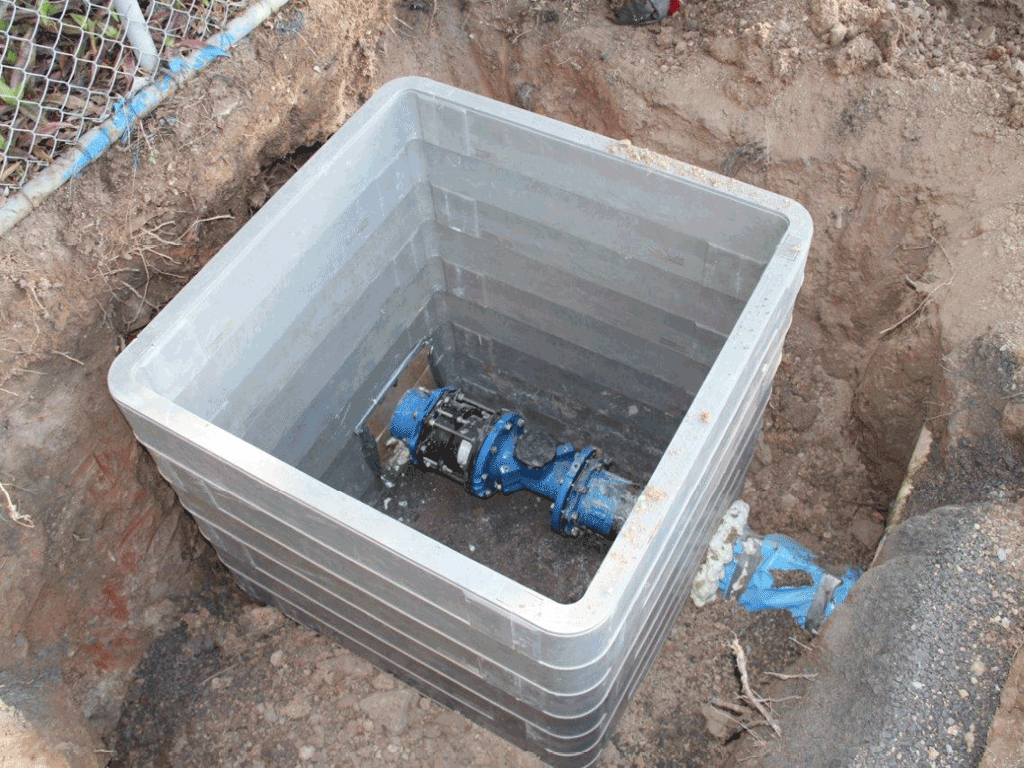

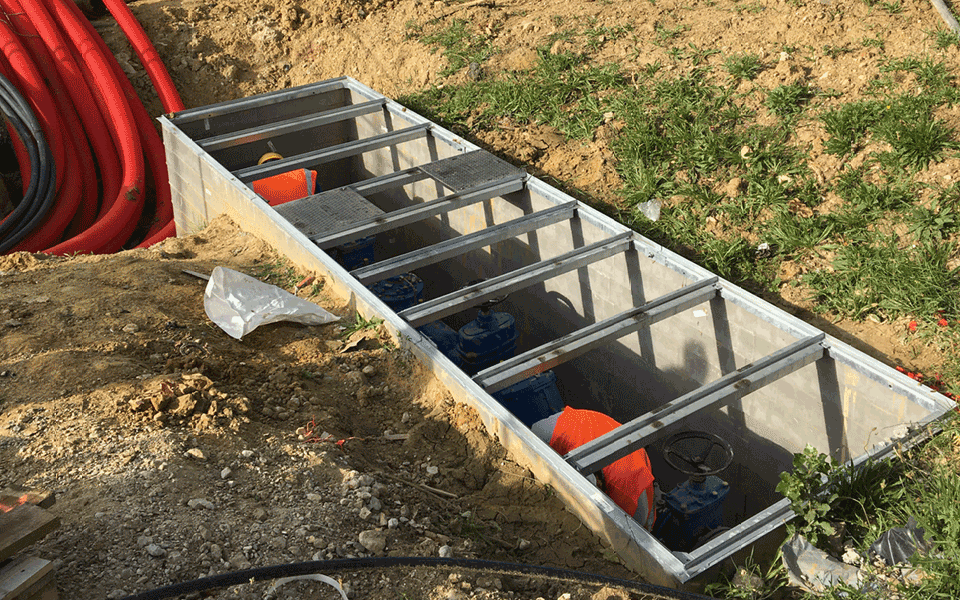

- Product: STAKKAbox™ ULTIMA Connect

- Load Rating: Class B

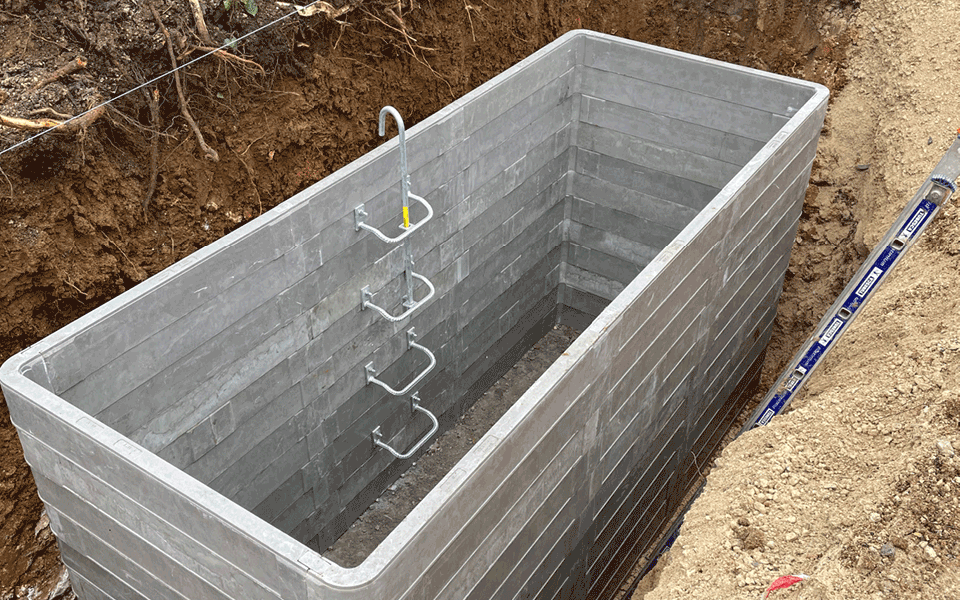

- Internal Dimensions (mm): 1000L x 1000W x 1500D

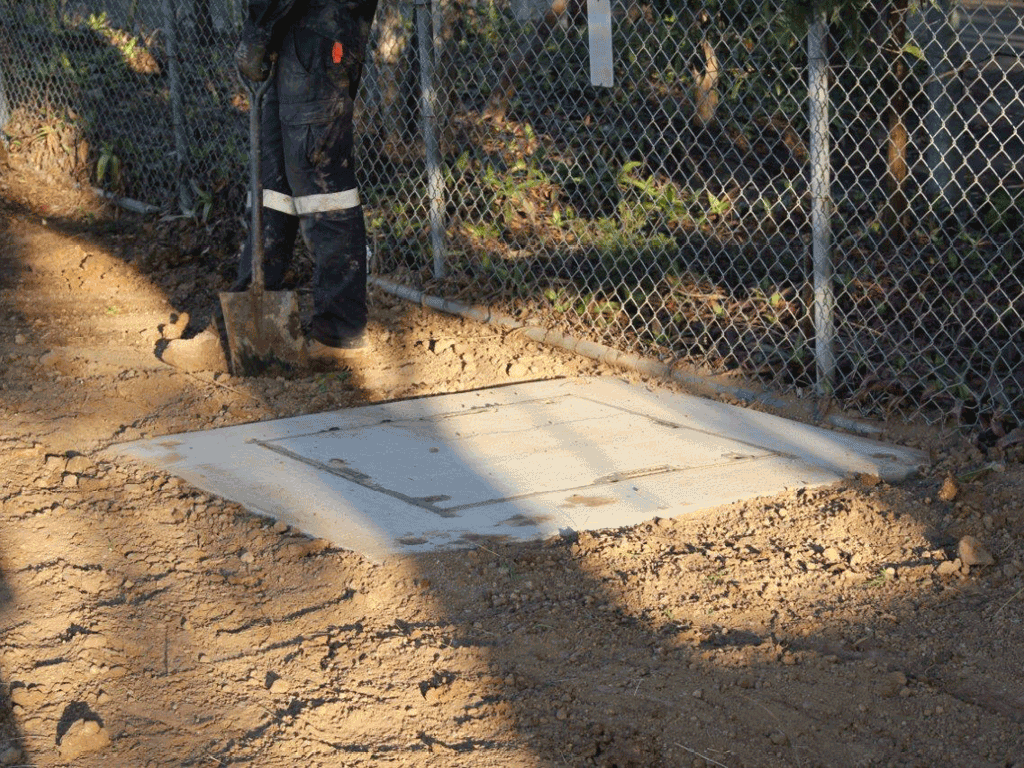

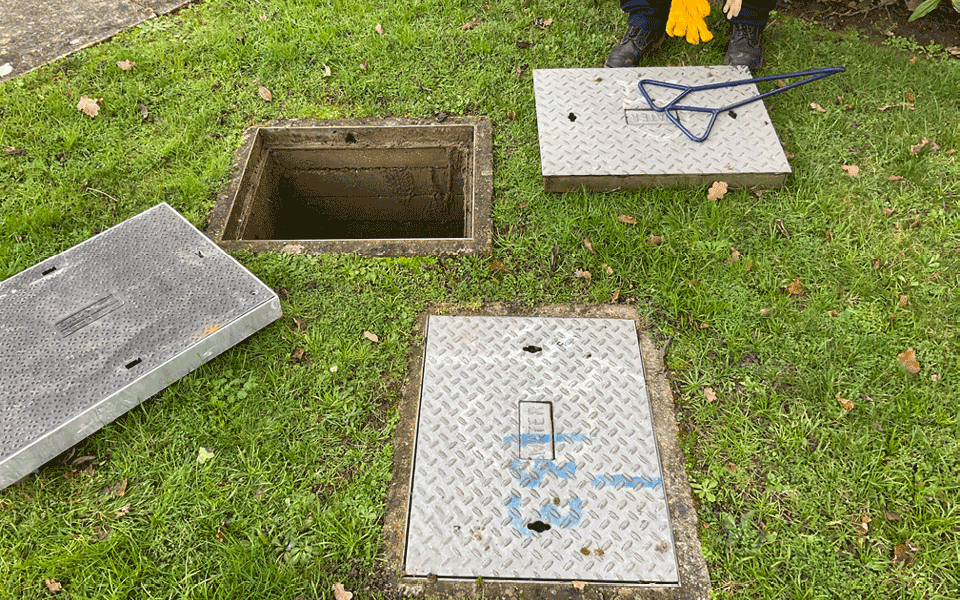

- Access Cover (mm): Precast Concrete Roof Slab with a 900L x 900W Class B Cast Iron Cover

Project Outcomes

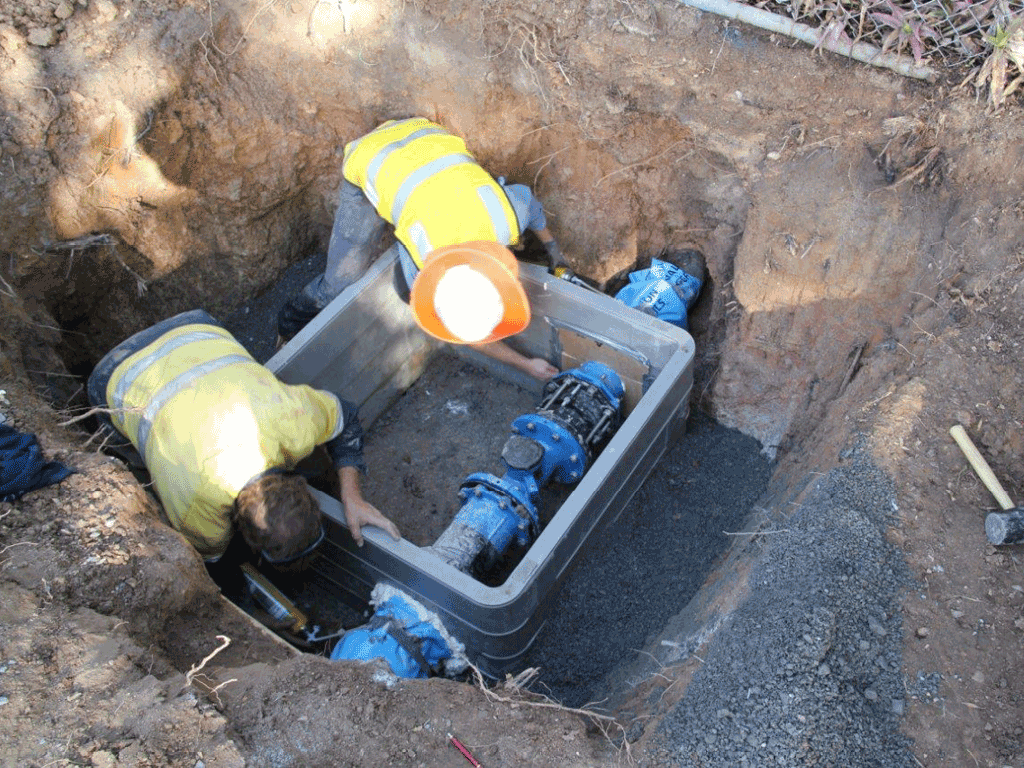

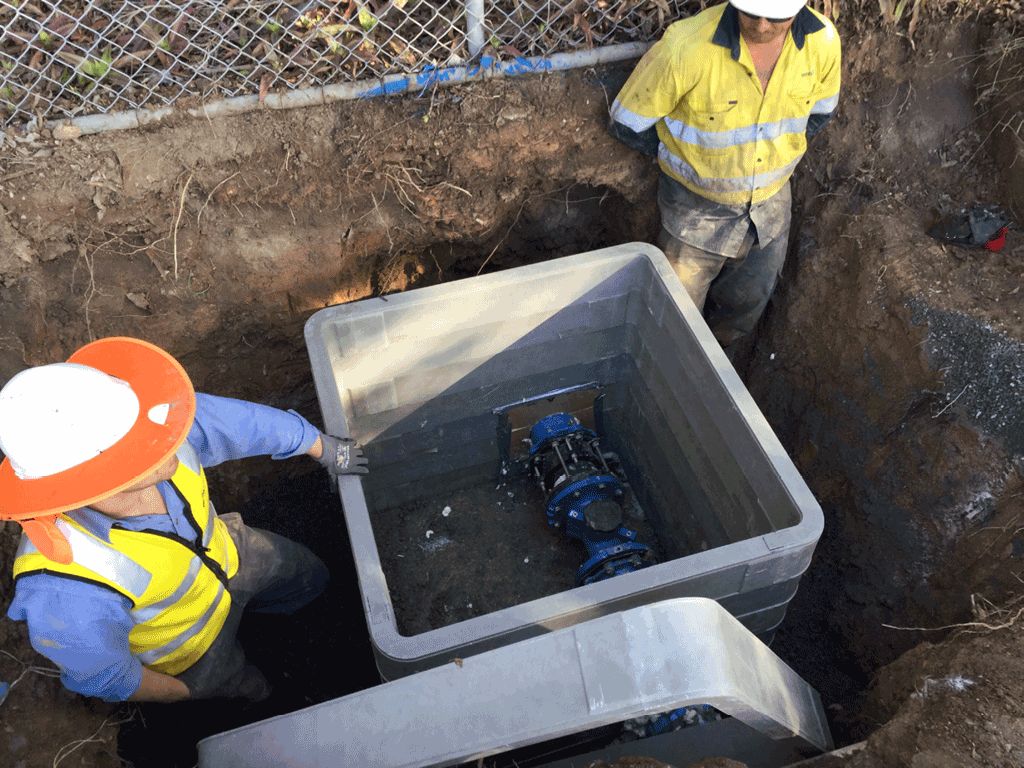

The modular and lightweight structure of the STAKKAbox™ ULTIMA Connect chamber system combined with its onsite modification capabilities provided the preferred solution for the project.

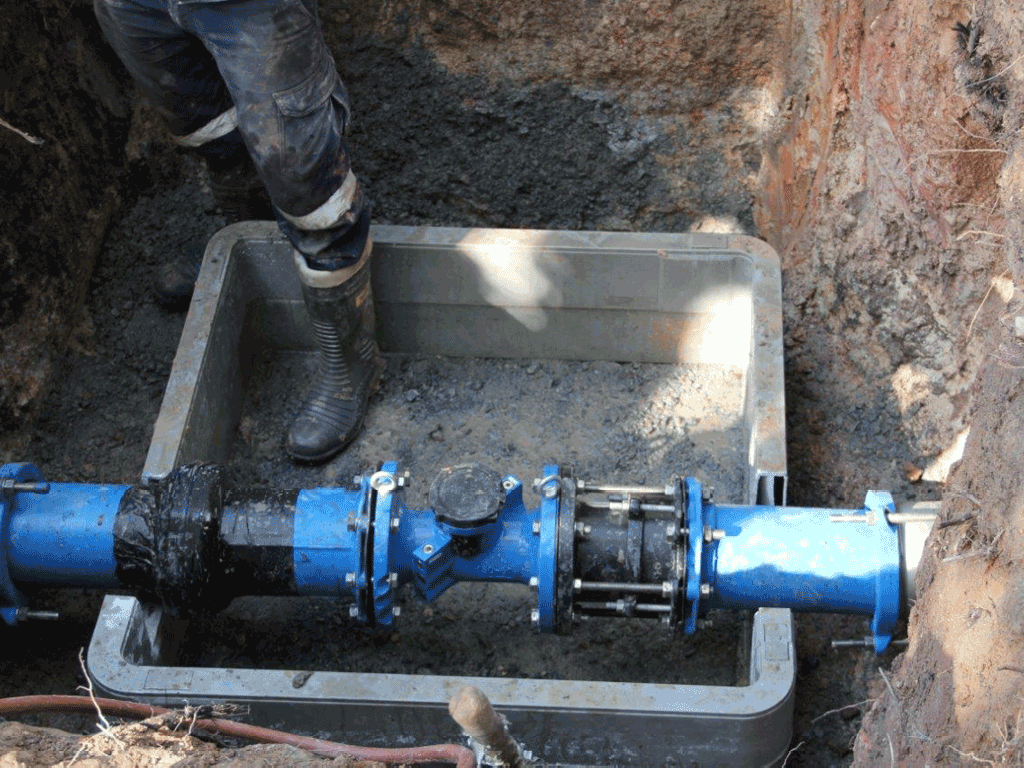

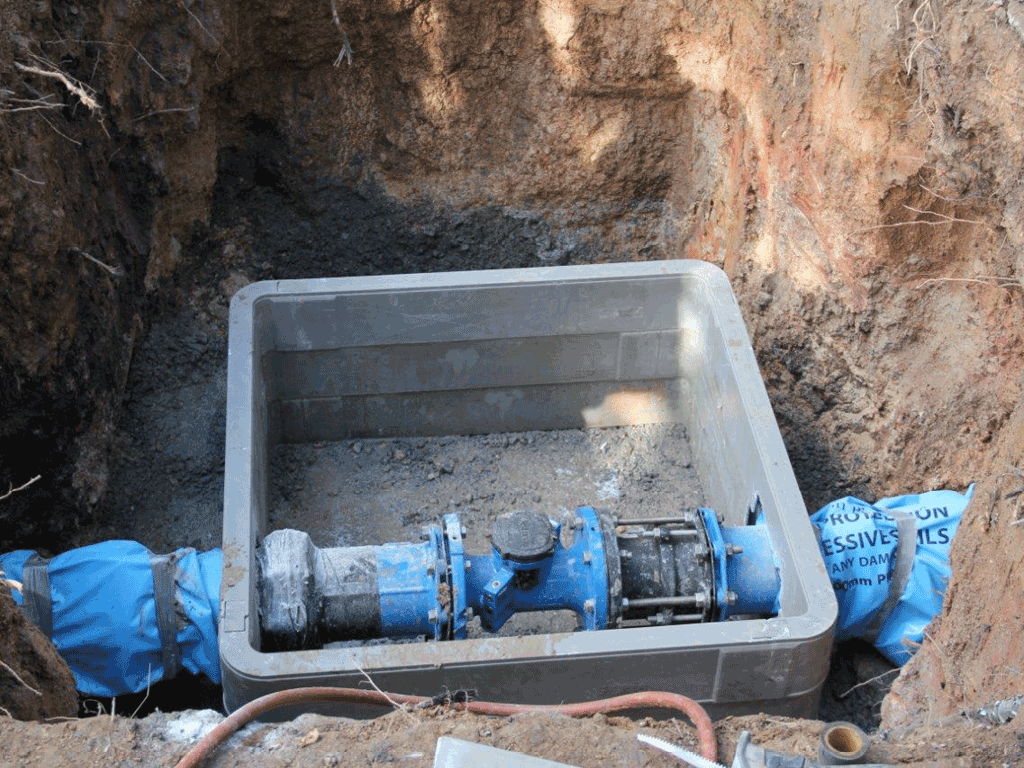

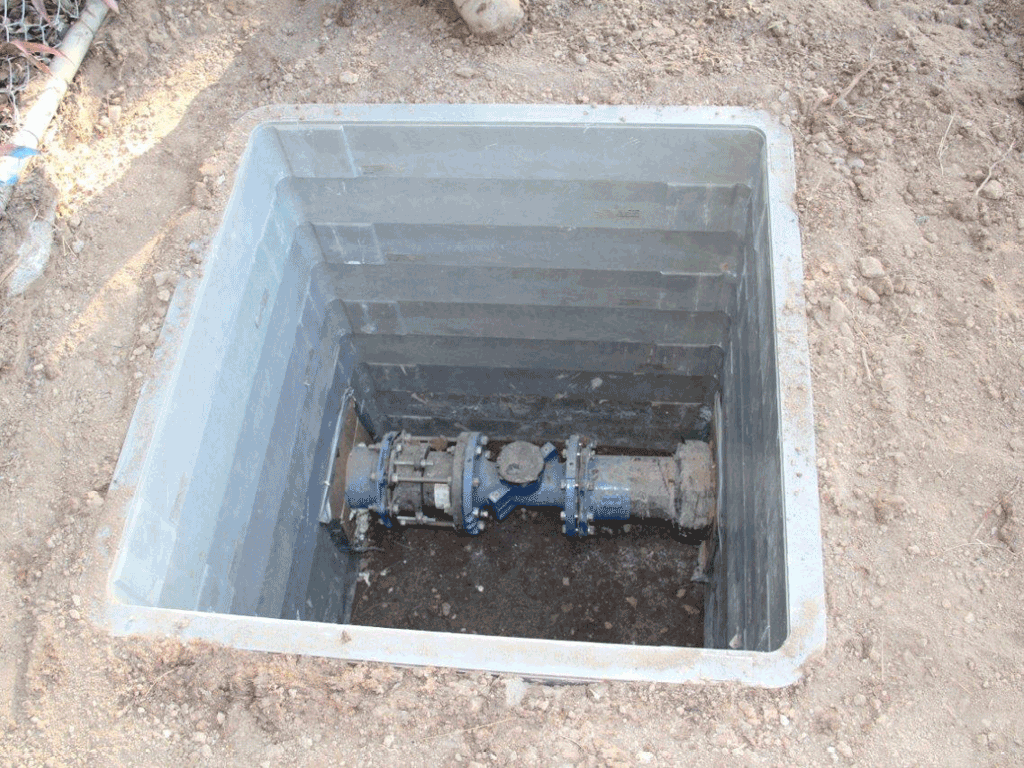

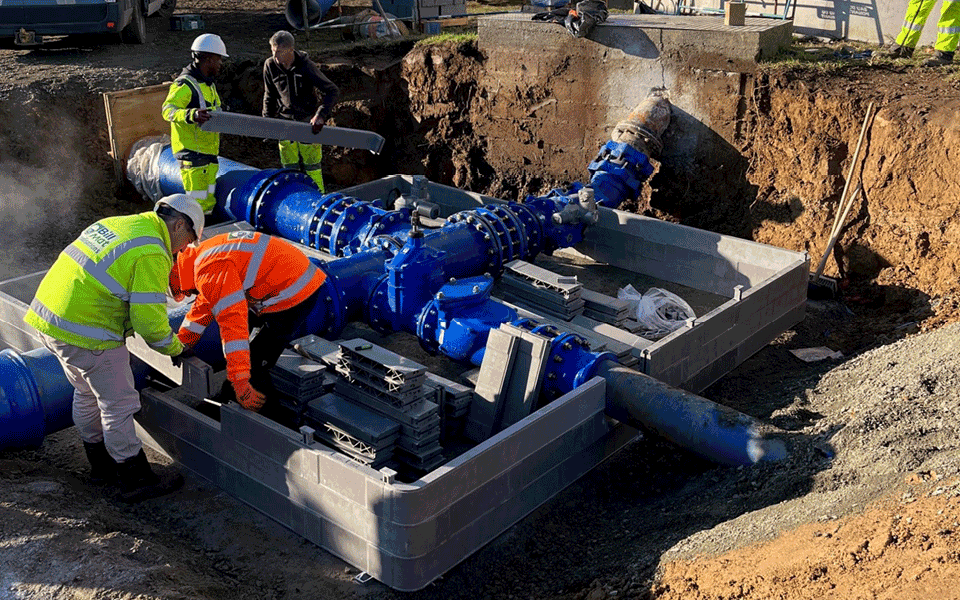

The STAKKAbox™ access chamber system was built around the existing 150mm water pipe buried at approximately 1300mm below ground. With time constraints a key consideration throughout this project, installation of the full chamber system was achieve within just one day, including excavation, cutting of the pipe and installation of the new flow water meter, assembly of the ULTIMA Connect chamber components and backfilling. Finally placement of Cubis’ precast concrete roof slab and cover was completed along with final landscaping.

The versatile modification capabilities provided by the STAKKAbox™ modular system enabled the ULTIMA Connect chamber to be built over and around the existing pipe work without the need for specialised tooling or builders.

Standard battery-powered and handheld tools, including a reciprocating saw and rubber mallet were all that was required to complete all the necessary modifications onsite. This ensured rapid installation of the new flow meter without any delay and in the end a very satisfied client.