Case Study Details

Client

Siemens and J Murphy & Son’s Ltd

Location

Richborough, UK

Product

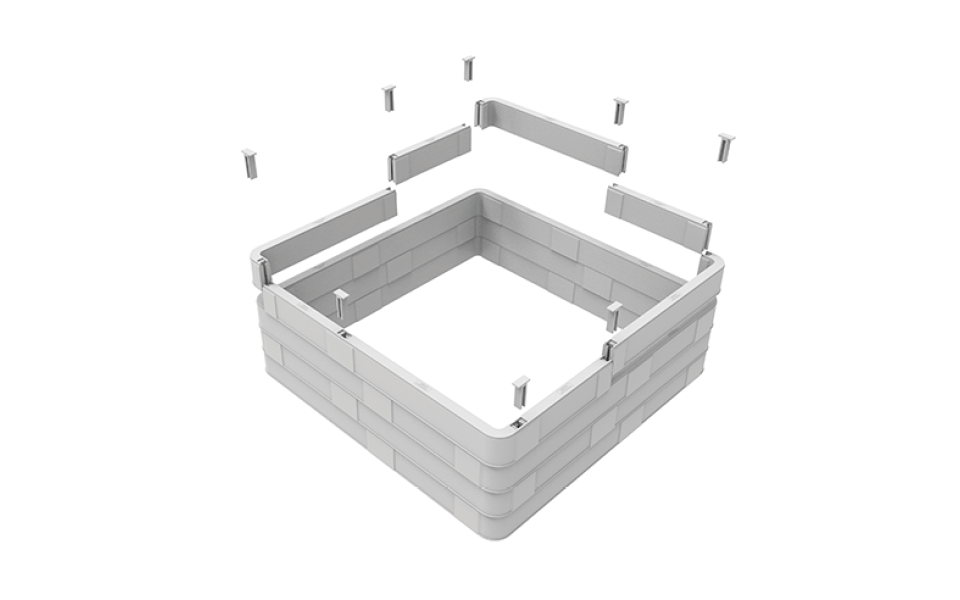

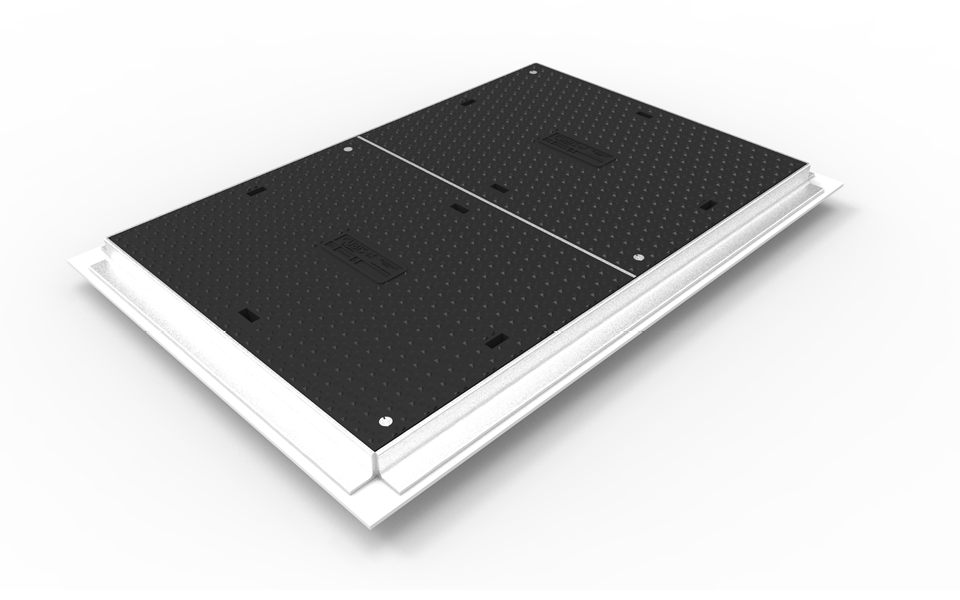

STAKKAbox™ ULTIMA Connect & AX-S™ Composite Access Cover, Concrete Cover Slab

Sector

Energy

Case Study

The Nemo Link® is a truly international collaboration in the construction of an electrical interconnector between the UK and Belgium’s electricity grids. Consisting of subsea and underground power cables connected to converter stations within each country, the cables allow for the flow of electricity in either direction.

The project involved building the power converter station on an 8 hectare site, formerly occupied by the Richborough Power Station. A similar converter station is being built in the industrial zone Herdersbrug in Bruges. The two sites will contain 24 converter towers with 2304 converter modules connecting consumers across European energy markets. Once completed the power converter station will be the largest in the UK.

The sites construction is a joint venture between National Grid and Elia with the groundworks delivered by Siemens and J Murphy & Son’s Ltd. As part of these construction works in the UK, Cubis Systems was approached to provide a HV receiver and diversion chamber system for use around the Richborough site.

Due to site location and complexity, the reduction of deliveries was of paramount importance for the contractors. Preliminary specification work was undertaken to determine the appropriate chamber and cover combination. This resulted in the delivery of 152nr 1.5m up to 2.6m ‘flat pack’ STAKKAbox™ ULTIMA Connect chamber systems for construction in-situ on site.

"The ease and speed of the installed STAKKAbox™ Connect chamber made operations stress free and gave a standardised format for the duct chambers and also reduced site movement not requiring crane or hi-ab use otherwise needed in traditional concrete installations" Main Contractor

The ULTIMA Connect chamber system had the added benefits of enabling the delivery of all the ‘flat pack’ components within 4 deliveries unlike a comparison concrete chamber that would have required 10+ deliveries. The individual 150mm deep sections of twin-wall GRP that make up the STAKKAbox™ ULTIMA Connect chamber system had the added flexibility of enabling the contractors to drill up to 300+ duct entries where required once installed as pre-drilling wasn’t possible due to extensive number of pre-existing power cables on site.